Metal-polymer pipes - the technical characteristics of such products cause a feeling of acute envy among all manufacturers of other types of rolled pipes.

After all, the alloy of metal and polymer gives these pipes high ring rigidity, excellent heat resistance, and absolute inertness to any aggressive substances. Therefore, multilayer metal-polymer pipes are gradually displacing their competitors from thematic departments of construction supermarkets and the hearts of potential buyers. And in view of the promise of this product, we suggest taking a closer look at such pipes: evaluating the material from which multilayer metal-polymer pipes are made, getting acquainted with the features of the product range and studying the installation process of such pipelines.

Advantages of ordering products in our store

- Wide range of pipes. From us you can order products of the required length and optimal diameter. Products are supplied in coils. This simplifies the process of transportation and use.

- Well-thought-out feedback system. You can ask our specialists any questions you have about the quality of the pipes offered and their characteristics. Managers will tell you about the features of the products. Our specialists will help you quickly make a choice in favor of those pipes that can successfully solve all the tasks.

- Possibility of exchange of goods of inadequate quality.

- Quick shipment approval and order confirmation. We sell all products on terms convenient for customers.

- Prompt delivery in Moscow and other cities.

Contact us!

Specialists will answer all questions regarding the sale of pipes and their return. The advantages of metal-polymer (metal-plastic) pipes are the absence of corrosion, resistance to overgrowth, the effects of aggressive building mixtures, strength, smooth internal surface, convenient transportation, technologically advanced, economical installation, impermeability to gas molecules, relatively low thermal linear elongation. VALTEC metal-plastic pipes are widely used in the installation of water supply systems, heating and cooling of buildings, and transportation of various technological media, including food.

Cross-linking of polyethylene inner and outer layers of the proposed metal-polymer pipes is carried out using the organosilanide method (PEX-b). The inner (working) layer has a crosslinking degree of 65%, the outer (protective) PEX layer has a crosslinking degree of 55%. This design solution makes the pipe more flexible. The metal layer is butt welded from pure aluminum foil with a thickness of 0.25–0.4 mm (for different sizes). The aluminum of the middle layer is welded using the TIG method, and the strength of the weld exceeds the strength of the aluminum layer itself. The strength of the adhesive connection of the layers is 70 N/10 mm, with the standard being 50 N/10 mm. Repeated temperature changes will not cause delamination of the metal polymer.

VALTEC PEX-AL-PEX metal-plastic pipes can be used in radiator heating (5th class of operation, GOST 32415-2013). Compliance with the passport operating conditions guarantees a 50-year service life of the product. The warranty period for VALTEC PEX-AL-PEX pipes is 10 years.

Metal-polymer pipes are an excellent combination of metal and plastic products.

They have proven themselves well as a material for cold and hot water supply, heating, underfloor heating systems, and transportation of process fluids. If all recommendations for installation and use are followed, their service life can be up to 50 years.

Valtec pipeline

Valtec metal-polymer pipes have become especially popular lately. They are used for heating, water supply, and cooling of buildings. The secret to the success of Valtec products lies in strict control over the production process and the high quality of the raw materials used.

Valtec uses an organosilanide cross-linking process (PEX-b). The manufacturer cross-links the inner layer by 65% and the outer layer by 55%. This allows Valtec to produce products that have high strength and excellent flexibility at the same time.

Also among the distinctive characteristics of Valtec products are:

- Light weight and practical length, which allow the pipeline to be transported and installed without much difficulty;

- Excellent sound-absorbing properties. Even with open installation, pipe lines do not require additional sound insulation;

- Possibility of hidden installation under a concrete screed, due to the small coefficient of linear expansion;

- High resistance to aggressive environments, which allows the pipeline to be used for transporting process fluids;

- Easily acquires the required shape and holds it;

- They have a diameter range from 16 to 40 mm;

- The sectional thickness of the pipe wall is from 2.0 to 3.5 mm;

- The manufacturer's warranty is 10 years.

In addition to the pipes themselves, the manufacturer also produces Valtec compression and press fittings. They are manufactured in all standard sizes and are ideal for the pipeline of the same name. Valtek fittings are distinguished by their excellent quality and maximum ease of use.

Metal-polymer pipes, as the name implies, contain metal and polymers. The structure and materials used are different, but products that have a layer of aluminum foil protected on both sides by polymer materials and polymer pipes with an internal mesh metal frame are widely used. Manufacturers of metal-polymer multilayer pipes present both versions on the Russian market.

Minuses

Among all the disadvantages of polymer pipes, the following can be identified:

- Can't stand direct sunlight.

- Over time, a loss of strength characteristics occurs.

- The impossibility of using them for fire-fighting pipelines.

- Impossibility of use in a heating system.

- Flammability of the material.

- Deform when exposed to heat.

Features of metal-polymer pipes

Manufacturing technology

The technology for manufacturing pipe products from metal polymers involves several stages:

- The inner shell is extruded from a special device (extruder).

- On top of the shell, using a special adhesive layer, a supporting layer of aluminum foil is applied, which is welded along the seam using a laser method, end-to-end or overlapping.

- The extruded outer shell is glued onto the aluminum layer.

- All layers are simultaneously pressed.

The outer layer of the pipe protects the aluminum from oxygen and moisture. Aluminum foil ensures the strength of the product, and the inner layer is designed to protect the product from exposure to the working environment and the formation of condensation.

Advantages over metal products

Thanks to this technology, multilayer metal-polymer pipes obtain physical and mechanical characteristics that are significantly superior to metal pipes. First of all this:

- resistance against corrosion and aggressive environments;

- good heat resistance;

- ease of installation;

- maintaining geometric shape after bending;

- resistance against internal deposits;

- high throughput, etc.

Purpose and marking of products

Metal-polymer pipes are used for laying water pipelines, heating systems and sewerage systems. They are also quite suitable for gas.

For a clear, unambiguous classification of products, international marking of metal-plastic pipes has been adopted. The main purpose of applying information is to convey to the buyer the maximum useful information about the product.

The following instructions will help you understand the markings, revealing the main encoding:

- Type of plastic used for manufacturing:

- PEX-AL-PEX - cross-linked polyethylene;

- PERT-AL-PERT - heat-resistant polyethylene;

- PE-AL-PE - simple polyethylene;

- PP-AL-PP - polypropylene.

- Products made of cross-linked polyethylene in the abbreviation may contain letters that indicate how the material was cross-linked (a-pyroxide, b-silane, c-electronic).

- Product diameter and (minimum) wall thickness. The value is given in millimeters or inches.

- The nominal (working) pressure for which the pipe is designed. If the operating pressure is maintained, metal-polymer pipes can withstand more than 50 years of operation without deformation or other violations of technical characteristics.

- Maximum pressure. A relevant parameter for pipeline products designed for transporting a high-temperature working environment.

- Information about the working medium that can be transported through pipes.

- Batch number and production date of the product.

Example of product labeling

Connection methods

The use of metal-plastic pipes for laying pipelines requires solving problems with connecting products to each other or fitting products.

To ensure reliable connecting nodes, the following are used:

- Threaded fittings with a sealing split ring.

- Press fittings.

Threaded fittings are easier to install and do not require special tools. However, this type of connecting unit is the main disadvantage of metal-polymer products, since the connections lose their tightness over time and require constant monitoring and tightening.

Connecting units formed using press fittings are more reliable, but they are one-piece and require a special press tool to organize them.

Decoding of production markings

The marking contains basic information about the characteristics and purpose of the pipeline. The sequence of values may differ from manufacturer to manufacturer.

Standard designations:

- name of the manufacturing company;

- production standard, certificate number;

- type of materials used;

- nominal dimensions;

- maximum permissible pressure;

- environment suitable for transportation;

- additional operating conditions (temperature).

At the end, the batch number, shift number and production date are displayed.

When assembling the pipeline, it is advisable to leave the surface of the pipe with markings within visual reach. In the future, information about the material may be needed

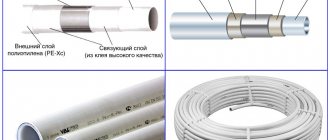

Multilayer metal-polymer pipes with an aluminum layer

Most of these pipe systems are intended for organizing heating systems (including floor heating) and water supply (cold and hot). The design of the products is indicated in GOST R 53630-2009 for multilayer metal-polymer pipes.

Layer structure:

- outer;

- adhesive;

- barrier;

- adhesive;

- interior.

Materials for the manufacture of metal-polymer pipes

In the production of metal-polymer pipes (MPP), the following can be used:

- ordinary polyethylene, PE or PEHD - for low-pressure cold water supply systems;

- heat-resistant polyethylene, PERT - for cold and hot water supply systems, as well as heating (up to 70 ° C) medium pressure;

- cross-linked polyethylene, PEX – high pressure and temperature pipelines, ultraviolet resistance (from some manufacturers);

- polypropylene.

The thickness of the aluminum layer differs among different manufacturers of metal-polymer pipes and can vary in assortment even within the same production. The thickness of the aluminum layer affects the rigidity of the pipe and should be selected based on the task at hand.

The adhesive composition is extremely important, because it is what forms the single, albeit multilayer, structure of the MPT. The main requirement is good adhesion to aluminum and polymer. The best manufacturers of such adhesives:

- Equistar, USA;

- Hyundai, South Korea;

- Mitsui, Japan.

Russian manufacturers of MPT

The best Russian manufacturers of MPT produce products not only for heating and water supply, but also for many technical and process pipelines.

Products under the COMPIPE brand are produced in the Moscow region (Kashira), and since 2015, partially in Switzerland. In addition to the standard purpose, pipes are used in the distribution of intra-house gas pipelines, in the heating of open areas, and in the organization of “warm floors”. The quality of MPT COMPIPETM made of cross-linked polyethylene, according to reviews, is high. There is feedback from the manufacturer. The company also produces fittings, fittings and tools under the Comtek brand.

NPP Mayak-93 is not only a manufacturer of MPTs, but also develops and supplies equipment for their production. In addition to the above capabilities, their pipes are intended for laying and insulating electrical wiring, in the systems of sea vessels and Russian Railways trains, as well as for technological needs (compressed air, aggressive liquids).

For heating and water supply, the Kazan Metal-Polymer Pipes company produces MPT, in which the inner and outer layers consist of polypropylene. Aluminum foil is welded "overlapping". The thermal conductivity of the walls is lower than with protective layers of polyethylene, so the coolant loses less thermal energy in the route.

The Komplekt-service+ LLC enterprise, Tatarstan, produces products using European technology and from European materials, however, their metal-polymer pipes comply with GOST R 53630-2009 and specifications approved by the Scientific Research Institute of Plumbing. They also use high temperature polypropylene as a protective layer with high resistance to chemical environments. Operating temperature – up to +110 °C. The fittings produced for metal-polymer pipes are universal and suitable for both MPT and polypropylene pipes.

A joint production between Russia and Italy produces Valtec pipes with polyethylene in protective layers. The production features make it possible to use such MPTs with frequent changes in ambient temperature with short-term “peaks” of up to 130°C.

Foreign MMT suppliers

The sales leaders are recognized manufacturers of multilayer metal-polymer pipes with technical characteristics that meet all the requirements of long-term operation. Warranties issued are often 10 years, which indicates the manufacturer's confidence in its products. Here are just a few of them:

Variety FRÄNKISCHE ROHRWERKE

- FRÄNKISCHE ROHRWERKE, Germany;

- HERZ, Austria

- HENCO, Belgium

- RBM, Italy;

- TECE, Germany;

- REHAU, France;

- GIACOMINI, Italy;

- COES, Italy.

There are many Italian and German manufacturers of high-quality MPT. There are also manufacturers from Korea and China on the market. When choosing the technical characteristics of metal-polymer pipes from various manufacturers, take time to study the product labeling. There are many fakes on the market, especially HERZ and HENCO, which do not correspond to the original pipes.

Smooth and corrugated pipes GIACOMINI for gas supply

Metal-polymer pipes have proven themselves well in heating, water and gas supply, and other areas. The products have a long service life and reliable guarantees, but beware of fakes and poor-quality installation - contact professionals.

Solving the leak problem

Troubles with leaks were associated exclusively with the method of connection with fittings.

To understand what exactly the problem is, you need to familiarize yourself with the structure of a metal-plastic pipe and the process of connecting sections of such products.

A metal-polymer pipe, by definition multilayer, consists of three main layers and two adhesive layers. In order, these are: plastic (usually mesh polyethylene, although there are options), adhesive, a thin aluminum tube with a welded seam, again adhesive, and on the outside there is a layer of plastic.

The procedure for connecting pipes using fittings:

- A split ring and a union nut are put on the end of the pipe.

- A chamfer is removed from the inside of the end, after which the fitting fitting is inserted inside. Reliability of the connection is ensured by the use of several rubber rings placed on the fitting, and polymer crimping of the fitting material - brass.

- The union ring is lowered, the nut is put on the thread and screwed. This provides additional crimping of the fitting.

The result is a tight, airtight connection with good waterproofing. However, after some time, due to the increased temperature of the coolant, the rubber rings lose their elasticity and ductility and simply begin to crumble.

This is the most common problem, but another possible problem is inaccuracy during assembly.

In particular, before connecting oval-shaped pipes, they should be carefully aligned using a calibrator and be sure to chamfer the ends. A high-quality calibrator for metal-plastic pipes will cope with this task without any difficulties.

Otherwise, the seals are likely to move and the connection will begin to leak almost immediately.

In this regard, metal-propylene pipes are much more reliable and resistant to high temperatures. In multilayer polypropylene pipes, aluminum performs only a reinforcing function, reducing the coefficient of thermal expansion.

Polypropylene, unlike polyethylene, can be welded (soldered), therefore, when assembling water supply or heating circuits from this material, you can use not only compression fittings, but also welding machines and electric couplings.

Another modern way of connecting metal-plastic pipes is the use of press fittings, in which the split ring is replaced with a brass sleeve. This connection is more airtight, but requires a crimping machine to make it.

GOST requirements for the manufacture of metal-plastic pipes

Requirements for the quality of manufacturing of a metal-plastic pipeline are imposed by GOST 53630-2009. The regulatory document defines the main classes of material by diameter, as well as maximum operating pressure, regulates raw materials for production, the procedure for packaging and transportation of products.

According to GOST, metal-polymer pipes are divided into two main groups depending on the diameter:

- Products 10-63 mm;

- Products 75-110mm.

GOST also regulates the production of products with the following nominal pressure:

- 0.6 MPa;

- 2.5 MPa.

The pipeline manufactured in accordance with GOST has a confirming quality certificate

You should pay attention to this when purchasing materials in stores.

GOST also determines product labeling. The first thing manufacturers should indicate is what kind of plastic is used to make the pipe. There may be several options:

- PE – polyethylene;

- PEX – cross-linked polyethylene;

- PERT – heat-resistant polyethylene;

- PP – polypropylene.

If cross-linked polyethylene is used for production, a letter designation (a, b, c) is applied to the product, indicating the cross-linking method.

Conclusion

Today, metal-polymer pipes are used everywhere. Pipelines made from metal polymers can be used for several decades. To maximize chemical and corrosion resistance, pipelines are coated with special galvanic solutions.

The strength of such pipes is several times higher than polymer ones; this is achieved through a special reinforcing metal frame. In the video presented in this article you will find additional information on this topic.

Did you like the article? Subscribe to our Yandex.Zen channel

Installation of heated floors made of metal-polymer pipes

Due to their long service life, high technology and ease of installation, metal-polymer pipes can be used for installing heated floors in a country house. The use of heated floors as a heating system for a country house is more effective than conventional radiators, primarily in terms of efficiency (in the Scandinavian countries, which are closest to us in terms of climatic conditions, currently over 80% of houses are equipped with heated floors). Savings occur due to the fact that with a warm floor there is no longer a need to increase the power of heating systems in order to warm up the coldest zone, which includes the floor. Before the advent of metal-polymer pipes, heated floors

were arranged only with the help of electrical cable systems, where the heat source was an electric heating element (cable) laid in a concrete floor. By using metal-polymer pipes instead of cables, you can stop using expensive electricity and, in addition, there is no need for additional insulation and grounding work.

In principle, work on installing a heated floor from metal-polymer pipes is carried out in the following sequence; 1. The base of the floor is covered with a layer of heat-insulating material, on which aluminum foil is laid to reflect heat rays. 2. Then a contour of several turns of a metal-polymer pipe is laid out on the floor, indicating the necessary heating zones. 3. The whole thing is poured with concrete with a layer thickness of 3-5 cm. 4. When the concrete hardens and gains its strength, it can be covered with any finishing material; parquet, linoleum, carpeting, ceramic tiles.

The main advantage of a heated floor made from a metal-polymer pipe is that the radiation of heat does not begin 20-40 cm from the floor, as when using wall-mounted radiators or heating panels, but the floor itself is heated. Thanks to this, the most comfortable temperature balance is created in the room with a smooth decrease in height. From the point of view of preserving the health of the inhabitants of the house, this scheme is more preferable than with conventional radiators under the window, in which the cold floor is combined with warm air rising from the radiators, which creates a large temperature difference and provokes the appearance of drafts. It is most justified to install heated floors from metal-polymer pipes in bathrooms, as well as in saunas and swimming pools.

CLAIM

A method of connecting multilayer metal-polymer pipes by welding through a connecting device having at least two connecting elements with seating sockets for the end sections of pipes, along the outer, inner and end surfaces of the final section of the pipe, covered by the internal surfaces of the seating socket of the connecting device, with preliminary simultaneous heating of the end section pipe and the mounting socket of the connecting device and subsequent combination of pre-heated sections of the pipe and the connecting device, characterized in that in order to avoid destruction of the polymer layers, exposure of the internal metal layer and removal of the adhesive layers of the pipe applied to the metal layer when combining it with the connecting device, the final section of the pipe is heated to the softening temperature of the material of the outer and inner layers of the pipe, and the mounting socket of the connecting device, made in the form of a connecting element of the connecting device of an annular groove coaxial with the internal hole of the mounting socket with a cylindrical wall on the side of the outer surface of the connected pipe, and a conical wall truncated along the plane of the end of the connecting element , the wall on the side of the inner surface of the connected pipe, is preheated to the melting temperature of the material of the connecting device, while preheating of the final section of the pipe and the mounting socket of the connecting device is carried out using a welding device having a control unit and a heater on which the pipe tool and fitting tool are located , while the temperature of the heater and the fitting tool having direct contact with the surface of the heater, equal to the melting temperature of the material of the connecting device, is set by the control unit and maintained by it at a constant level within a given error, while limiting the heating of the final section of the pipe to a temperature not exceeding the temperature softening of the material of the outer and inner layers of the pipe is ensured by fixing the pipe tool to the heater through the adapter sleeve, while in order to adjust the heating temperature when external conditions change, the pipe tool can move along the axis of the adapter sleeve.

How to choose a product: price and quality

Before purchasing metal-plastic pipes, familiarize yourself with the manufacturing technology and the number of layers, how the connection and welding were carried out. If the welding was carried out with a laser, then there will not be a single seam on the product; such a pipe is high-quality and expensive, and very durable to use.

If the product is ultrasonic welded, the metal overlaps with the plastic. In this method, compensation was used for the thick weld that was formed during manufacturing, thus the metal layer became thinner. This means that the product is fragile and installation causes some difficulties. Metal-polymer pipes are very popular.