What it is

Crosslinked is polyethylene with a modified mesh structure. Its molecules are connected to each other by additional lateral bonds. Cross-linking provides the material with maximum density and reduces its thermoplasticity.

Scope of application

Cross-linked polyethylene products are used in the production of:

- pressure water pipes;

- parts of hot water supply pipelines;

- gas pipelines for underground installation;

- elements of heating systems;

- protective sleeves for high voltage cable networks;

- various parts and elements in instrument making;

- special building materials.

Technical characteristics of cross-linked polyethylene

- Density 0.94 g/m³.

- Tensile strength 22–27 MPa.

- Elongation at break 350–550%.

- Elastic modulus more than 550 MPa.

- Impact resistance 441 kJ/cm².

- Shore hardness 64.

- Vicat hardness 124.5 ºС.

- Operating temperature range -100…+100 ºС.

- Temperature:

- softening - 150 ºС;

- melting - 200 ºС;

- combustion - 400 ºС.

- Linear expansion coefficient 1.4*10⁻⁴ (ºС⁻¹).

- Thermal conductivity coefficient is 0.35–0.41 W/mºС.

- Flammability class - G4.

- Flammability class - B3.

- The toxicity class of combustion products is T3.

Kinds

The material is divided into types depending on the method of stitching:

- Peroxide. Cross-linked with hydrogen peroxide. The process takes place under pressure and covers up to 85% of the molecules.

- Silane. Chemically cross-linked, when the raw material is saturated with organic silanides and hydrated. The resulting polymer has up to 70% cross-linked structure.

- Radiation. During cross-linking, the polymer is exposed to the energy of ionizing radiation. The proportion of linked molecules is up to 60%.

- Nitric. Nitrogen compounds are used for crosslinking. The structure of polyethylene with this method is 70% cross-linked.

Receipt

Cross-linked polymers are obtained by polymerization or polycondensation of polyfunctional monomers, less commonly oligomers. In addition, mesh plastics are often obtained by cross-linking ready-made linear or nonlinear macromolecules. Cross-linking occurs across reactive groups when exposed to chemicals called cross-linking agents, and can also be achieved by exposing polymers to high-energy radiation.

When a polymer network is formed, the system gradually changes its properties. Thus, the viscosity of the polymer, the glass transition temperature, and the elastic modulus increase. When a certain critical degree of cross-linking, called the “gelation point,” is reached, the material acquires the properties of insolubility and equilibrium elasticity. At the same time, the proportion of insoluble part, the so-called, appears and increases in the system. “gel fraction” and the proportion of soluble polymer, the so-called “sol fraction”, decreases.

The position of the gelation point is significantly influenced by the reaction conditions, mainly the participation of an active or passive solvent in the process. It is also important to fill the polymer with components that can influence the chemical interaction of system components or selectively absorb them or reaction products. This can be soot, various fibers and other fillers, pigments, etc.

Advantages and disadvantages

Products made from cross-linked polyethylene have the following advantages:

- high tensile and tensile strength;

- wear resistance;

- crack resistance;

- frost resistance;

- dielectric properties;

- corrosion resistance;

- easily withstands high temperatures;

- high resistance to chemicals;

- biological resistance.

The disadvantages include:

- Instability to ultraviolet radiation.

- The ability to oxidize when oxygen penetrates into the structure of the material. To mitigate this disadvantage, the material is coated with a film of ethylene vinyl alcohol: it reduces the diffusion of the outer layer.

Some structural features

Conventional non-crosslinked material is produced under low pressure when catalysts are present. It has large polymer molecules with side branches. Most of them are in some kind of free “floating” in the space between molecules. Cross-linking allows you to achieve lateral bonds that create an intermolecular network. As a result, it is possible to obtain a particularly strong structure, which has the appearance of a crystal lattice of solids.

When different cross-linking techniques are used, the result is a substance with a certain number of bonds, indicating greater or less impressive strength. Some versions of cross-linked polypropylene are obtained in the presence of hydrogen peroxide and have the highest percentage of cross-linking, which can reach 85%. The most common and applicable in a wide range of products is silane polymer, which has a 70% bonded structure.

Cross-linking will be 60% if the technology provides for a radiation manufacturing method. In the presence of nitrogen, a material is created with rather complex reaction conditions. As a result, it is possible to achieve the same 70% cross-linking. Cross-linked polypropylene with a high percentage of cross-linking is more expensive and has the greatest crack resistance, high melting point and impressive impact resistance. This cross-linking makes it possible to achieve higher hardness and less ductility of products, which does not mean high quality, but allows you to obtain various materials that will have their own purpose.

Which is better - cross-linked polyethylene or metal-plastic?

Products made from cross-linked polyethylene, polypropylene and metal-plastic have many of the same characteristics:

- corrosion resistance;

- elasticity;

- strength;

- durability;

- convenient installation.

But metal-plastic pipes heat up faster and have greater thermal conductivity. This is an advantage for using them in heating systems. However, the metal plastic has a different coefficient of linear expansion of the layers, which can lead to wall delamination. It won’t even withstand several cycles of freezing and thawing; it will simply burst.

Products made from cross-linked polyethylene do not have all these disadvantages. But they must be installed with care so as not to damage the anti-diffusion protection layer on the outside.

Polyethylene cross-linking technologies and comparison with polypropylene

It is clear that the implementation of this technology requires an understanding of the specific problems associated specifically with the use of plastic under conditions of high pressure and elevated temperatures. Thus, it is known that the use of ordinary polyethylene as a material for pipes is possible only for cold water supply, but not for heat supply due to the low long-term strength of polyethylene. An alternative to conventional polyethylene can be a material such as “cross-linked” polyethylene, which has strength properties that allow its use in the production of pipes for heat supply. The main production technology options and some physical properties of cross-linked polyethylene are described below. Technologies for the production of cross-linked (X) polyethylene

There are several types of polyethylene - a product obtained by polymerization of ethylene, o low density (LDPE);

o medium density (MDPE); o high density (HDPE); o ultra-high molecular density (UHMWPE) cross-linked (PEX). In regular (raw or non-crosslinked) polyethylene (PE), the long molecules are not bonded to each other in the polymer matrix. At the same time, such mechanical properties as rigidity, tensile strength, etc. depend decisively on the relative position and “entanglement” of the molecules. It is therefore not surprising that the possibility of forcibly linking molecules to each other is of great interest. The chemical bonding of molecules, known as cross-linking, changes the properties of raw polyethylene to such an extent that it becomes possible to use the material for pipes in heating supply. (Note that physical cross-linking is also possible due to the presence of small inclusion particles; it is not considered here.) However, interest in cross-linking has also led to a fair amount of confusion regarding production methods and the benefits of this or that technology. What is PEX?

PEX is a designation for cross-linked polyethylene.

The last sign should not be considered the letter X - it is just a symbol of the cross (an ancient Western tradition that originated in Christian literature). There are three PEX production technologies: 1. Peroxide (heating in the presence of peroxides); 2. Silane (moisture treatment of HDPE, into which silane + catalyst was previously implanted); 3. Radiation (irradiation with electrons). In European standards, the following designations are adopted: PEX-A, PEX-B, PEX-C. All three technologies cross-link individual polyethylene molecules together at different locations to create a network. Accordingly, the concept of the degree or density of cross-linking (gel percentage) is introduced as a percentage, which reflects the proportion of the number of bonds between polyethylene molecules. The recommended value is 65-80%. To experimentally determine the crosslink density, having a sample of the material in hand, use the xylene extraction process according, for example, to the American standard ASTM D2765. The main purpose of crosslinking is to obtain thermal stability of the material under pressure. For example, for pipes made of high-density polyethylene (HDPE), the possibility of carrying out continuous loads at a temperature of 60°C is extremely rare. After cross-linking, the operating temperature can reach 100-120°C. The specific limit depends on the initial density, degree and type of crosslinking. ESCR (Exposure to Cracking Resistance) is also significantly improved. The tensile strength remains the same or slightly higher, but the elongation at break becomes less. Crosslinking makes polyethylene tougher. ~1~ Cross-linked polyethylene is characterized by such parameters as: o the proportion of cross-linking; o the proportion of material in the form of a crystallite; o tensile strength; o elongation at break. Peroxide technologies

Peroxides are certain chemicals that are activated at elevated temperatures, generating free radicals.

The radical abstracts a hydrogen atom from a carbon atom in the polyethylene chain, leaving a PE radical. Such an active molecule can combine with a similar one and form a bond, i.e. stitching. The most popular peroxide is 2,5-dimethyl-2,5-di-(butylperoxy)hexane. At room temperature it is in the liquid phase, but can be adsorbed on a wide variety of surfaces. At high (180-220°C) temperatures it decomposes, forming free radicals. The peroxide is adsorbed on lumps or coils of polyethylene, then the mixture is fed into a cylinder with a reciprocating piston, where it quickly melts (Thomas Engel process). Passing through a conventional die, polyethylene is formed into a pipe. Further heating of the resulting still liquid pipe leads directly to the crosslinking reaction and the peroxide performs its task. The most important thing in this process is to provide the right thermal profile to prevent too early cross-linking in the extruder barrel, which in turn prevents large pressure losses. In such cases, it is recommended to use special screws. Only this technology (peroxide) crosslinks in the molten phase. This ensures a random distribution of cross-linking “stitches” throughout the melt volume. The consequence is also a lower density of the hardened material. Temperature control is fundamentally important here. Typically, peroxide suppliers take the trouble to provide the manufacturer with the necessary temperature-time dependencies. The maximum crosslinking fraction is determined by the amount of peroxide. Silane

This technology was born in the late 60s.

There are two varieties: monosil and sioplas. Monosil technology introduces vinyl silane into polyethylene at the time of conventional extrusion of a polyethylene pipe. The sioplas technology uses a ready-made mixture of polyethylene and silane supplied by the polyethylene manufacturer - polyethylene + vinyl silane + peroxide. A rubber catalyst (the so-called “accelerator”) is added to this mixture, all of which is subsequently fed into an extruder to be converted into a pipe. In both cases, the pipe at the exit from the extruder “reaches” its condition in a steam bath at high temperature for several hours, where the crosslinking process occurs (already in the solid phase) due to the diffusion of moisture into the material (water reacts with silane, forming active radical groups , which cross-link polyethylene molecules). In principle, this diffusion limits the rate of the process. Here cross-linking occurs in the solid phase. Those who prefer to use monosil technology do everything themselves. Those who use sioplas technology must choose where to buy silane-saturated polyethylene and where to buy catalyst rubber. It should be borne in mind that saturated polyethylene is not stored for a long time - a maximum of 4 to 6 months. The main thing in monosil, compared with sioplas technology, is the adsorption of liquid silane by a porous polymer carrier (coils, etc.). This is the main reason for the improved dispersibility of silane, which makes it possible to produce large cross-section pipes. Pipes using this technology can withstand temperatures up to 110°C. The maximum crosslinking fraction is determined by the amount of vinyl silane and the exposure time in the steam bath. Radiation

Irradiation of polyethylene with electrons at moderate temperatures does not require the addition of any substances.

In practice, the pipe passes through the linear accelerator many times. The higher the dose (usually expressed in megarads), the greater the proportion of cross-linking that also occurs in the solid phase. The maximum cross-linking fraction is determined by the radiation dose. What's better?

The resulting cross-linked polyethylene structures and thermomechanical properties differ from each other under different technologies.

To answer the question “which technology is better”, a comparison was made [1]; The test sample was the same material - HDPE with implanted vinyl silane without a catalyst. The process conditions for three technologies - peroxide, radiation and silane (hereinafter designated as 1, 2 and 3, respectively) were as follows: 1. a mixture of raw materials with peroxides was processed at 170°C. 2. the raw material was irradiated with 1 MEV radiation. 3. A mixture of raw materials (95%) and accelerator (5%) was exposed to moisture in humid air (90% humidity) at 40°C. Measurements during the experiments were carried out regarding: o the proportion of cross-linking; o behavior of the material during crystallization; o properties of the melt (at 190°C); o resistance (at 150°C); o elongation at break (at 150°C). The figures below show the results of studies of the properties of materials obtained using three technologies. In Fig. 1-3 ~2~ shows the influence of the parameters corresponding to the three technologies on the crosslinking fraction. In Fig. 4-5 ~2~, ~3~ - influence of the crosslinking fraction on mechanical properties. In Fig. 6 ~3~—influence of cross-linking fraction on the degree of crystallinity. The numbers in brackets above the curves indicate technologies: 1 - peroxide; 2 - radiation; 3 - silane. Rice. 6 ~3~ gives the following conclusion: the fundamental difference between silane technology is that the fraction of crystallinity of the material does not depend on the degree of cross-linking (the sample retains the crystalline phase unchanged at any degree of cross-linking). The explanation for this fact is as follows: the formation of the structure of the crystalline phase occurred during the implantation of silane into the original polyethylene (at the polyethylene manufacturer, for example, in the case of sioplas technology). Thus, in the raw (original) polyethylene, the placement sites of vinyl-silane formed a crystalline structure (slightly less than 70%, as can be seen from Fig. 6 ~3~). Subsequent stitching occurs precisely at these center points. Therefore, cross-linking cannot change the crystallinity, because this had already been done before her by the introduction of silane. But for peroxide or radiation technologies, the stitches don't necessarily happen where the silane is placed - rather in random places. So, sinal technology preserves crystallinity, one of the main parameters of the polymer. As for the mechanical properties, from Fig. 4-5 ~2~ , ~3~ we can conclude that cross-linking is more uniform in the case of peroxide technology (curve 1). In general, the difference is insignificant. From a consumer point of view, any of the technologies gives similar results if all process conditions are met. Peroxide technology requires a piston extruder or an extruder with suitable modifications due to the high back pressure generated in the extruder barrel at the time of crosslinking. Peroxides must be handled with care. The possibility of varying the final cross-linking in this method is maximum. The degree of crosslinking is directly proportional to the amount of peroxide, antioxidant level and temperature. But this is also the most demanding process. Silane technology is less demanding and can be performed on almost any extrusion equipment. The only drawback is the need to operate the steam bath in strict accordance with the speed of the process. The ability to recycle (process) cross-linked polyethylene using this technology back into the original (raw) polyethylene can be considered an advantage. To do this, the material is processed in water or methanol at high temperatures (above critical). The polyethylene obtained in this way has the same molecular weight as crude polyethylene, and the gel fraction (crosslinking fraction) can be achieved to zero. The physical and mechanical properties are practically no different from those of the raw material. Silane technology generally allows for a more flexible and cost-effective crosslinking process. In contrast to other methods, polyethylene is cross-linked by silane-oxygen-silane radicals rather than carbon-carbon radicals. The disadvantages of the radiation method include its high cost. It is used more often in the production of heat-shrinkable sleeves or insulating material for cables. Its advantage over peroxide technology (the same as silane technology, however) is that cross-linking occurs in a ready-made object. Despite the shortcomings of this method, the number of its adherents is steadily growing. Comparison of PEX with polypropylene

Polypropylene is obtained by polymerization of propylene. Its varieties: o homopolymer (PP-H); o block copolymer (PP-B); o random copolymer (PP-RC). One of the main indicators of pipe quality is resistance to long-term loads, both from pressure and temperature. It should be noted that there is a pronounced temperature-time dependence of the strength of polymer pipes. For pipes made of cross-linked polyethylene, this dependence has a standardized form: ~5~, where s is the hoop stress (in American literature), MPa; t—temperature, K; T—life or operation life, hours; A = -105.8616; B = 57895.49; C = -24.7997; D = -18506.15. The values of these coefficients are established in the international standard ISO 15875 “Pipelines for hot and cold water supply made of cross-linked polyethylene”. For polypropylene there will be not one, but two equations, which is due to the presence of a transition from plastic to brittle type of fracture at elevated temperatures and service life (ISO 15874): A = -55.725; B = 25502.2; C = 6.39; D = -9484.11; A1 = 19.98; B1 = 9507; C1 = -4.11. In Fig. 7 ~6~ shows the dependences of “permissible hoop stress depending on service life” for cross-linked polyethylene (PE-X) and polypropylene (PP-C) at an operating temperature of 95°C. We see that the rate of decrease in strength with increasing temperature for polypropylene pipes is much greater than for cross-linked polyethylene. Let us further compare PEX and PPRC, taking in both cases pipes of type PN20 (type PN40, for example, means, by definition, that this pipe can withstand a pressure of 40 atm at 20°C for 50 years) with different outer diameters of 20 and 110 mm and Let's compare the wall thicknesses: ~4~ The wall thicknesses of PEX pipes are smaller than for PP pipes. Let us now compare the permissible operating pressures for PN20 pipes at different temperatures, but under one general condition, the service life is 50 years: ~7~ From this comparison it is clear that PEX pipes are able to withstand higher pressures at high temperatures than PPRC pipes. Installation of polypropylene pipes under channelless installation conditions is carried out in straight sections, requiring special technologies for connection (welding, soldering, glue). Strong stresses occurring in PP pipes require the installation of compensation devices. PEX pipelines do not have all these disadvantages, since they are flexible and self-compensating routes, the installation of which is carried out using coils. Replacing steel pipes with PEX in urban conditions is superior to replacing them with propylene, because... It is in this case that a particularly masterly laying of the route is required, preserving the existing structure of other communications without changes. If we consider the trends in the use of different plastic pipes in Europe, then, again, PEX is in the lead (Fig. 8 ~6~). It should be noted that in a number of regions of Russia there is experience in the practical use of plastic pipelines in polyurethane foam insulation and a waterproof polyethylene sheath. The TVEL production association has mastered the production of pre-insulated pipelines in polyurethane foam insulation with a protective layer of polyethylene and a supporting pipe made of cross-linked polyethylene. To date, the maximum amount of work on laying new and replacing old heating mains has been carried out by the association in the city of Neftyugansk. Work was also carried out in St. Petersburg, Surgut and other cities. It is interesting to note an example of replacing a worn-out heating main laid by the channel method in the city of Veliky Novgorod. The pipes that had become unusable were dismantled, and instead a plastic pipeline 50 m long and a supporting pipe diameter of 110 mm was laid in an existing reinforced concrete box. During hydraulic tests, it was in an unfilled state. At the moment of applying pressure and temperature (7 atm, 50°C), the pipeline showed no signs of deformation.

References 1. S. Venkatraman, L. Kleiner Propeties of three types of crosslinked polyethylene. Adv. in Polym. Tech. 9, 3, 1989.

PEX pipe joining method

PEX pipe products are produced from different types of cross-linked polyethylene and differ in their characteristics. Types of markings:

- RE-Ha. Cross-linked using the peroxide method. Uniform structure with the largest number of cross-linked molecules, durable and safe for human health.

- PE-Xb. Crosslinked using the silane method. No less durable products than peroxide polyethylene pipes, but more rigid and less able to restore their original shape. Some varieties contain chemicals and are intended only for the manufacture of cable sheaths. Therefore, when choosing water pipes, you need to be guided by the data in the hygiene certificate;

- PE-Xs made from radiation cross-linked polyethylene are more rigid, prone to creases and are inferior in structure uniformity to peroxide materials.

Major manufacturers of polyethylene pipes

On the modern construction market you can find a large number of different polyethylene pipes from a variety of manufacturers. Therefore, any person who decides to install a pipeline on their own involuntarily has the question: “Which brand should I prefer?”

The most reliable manufacturing companies, according to experts, are:

- "Rehau", "Vega", TESE, Polymutan (all Germany).

- KAN (EU).

- Virsbo (Sweden).

Among the budget options, it is worth paying attention to the products of such companies:

- "Aquatherm Polska" (Poland)

- DAK-K (Ukraine).

Tips on how to choose

The selection of pipes should begin with a visual inspection. They must have a smooth surface. Slight waviness and the presence of longitudinal stripes are acceptable provided that they do not thicken the wall beyond the permitted values. In addition, the pipes must have a uniform color, and the surfaces must be free of cracks, bubbles, foreign inclusions, and cavities.

Information on the main characteristics of pipes is included in the marking. From it you can find out what type of stitching was used in manufacturing, as well as the geometric parameters of the product.

Popular manufacturers

Pipe products from the following brands have proven well:

- TECEflex (Germany). The company produces pipes of the PE-Xs brand. Crosslinking is carried out by the electron beam method. Ethylene vinyl alcohol is used for anti-diffusion protection. It forms an oxygen-blocking layer that is resistant to mechanical damage.

- UNIDELTA (Italy). Manufactures pipes with an internal protective layer of EVOH, cross-linked using the silane method.

- REHAU (Germany). The company produces products from peroxide polyethylene with an external anti-diffusion coating, painted red.

approximate price

Materials made from cross-linked polyethylene are cheaper than polypropylene products, which are also used for assembling plumbing and heating systems. The cost of PEX pipes depends on the method of cross-linking polyethylene.

Reviews on the use of material for household needs

A warm floor made of cross-linked polypropylene, according to home craftsmen, will be a highly efficient system. Such pipes are considered today the most modern choice, since their characteristics fully meet the requirements. Among the disadvantages here, according to buyers, one can note only low flexibility, due to which the products do not hold their shape well during installation.

Cross-linked polypropylene is also used quite often for heating. However, here, as consumers emphasize, problems may arise due to the oxygen permeability of the material, which may cause the activation of corrosion processes on structural elements. Therefore, for heated floors, for example, experts advise using pipes with diffusion protection.

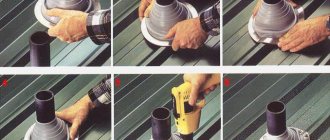

Connection methods

Polyethylene pipes are connected in three ways:

- Compression fittings. Compression-type fittings are easier to install and can be used to assemble cold and hot water supply pipelines.

- Press fittings. With the help of press fittings, permanent joints of parts are obtained. Due to the property of the material to restore its shape after deformation, the polymer molecules in the joint area straighten after crimping and fill all the gaps between the pipe and the connecting elements. The result is a pipeline with very reliable connections that do not require additional maintenance.

- Electric welded couplings. The electric welding method promotes the formation of monolithic joints that are not inferior in strength to the product itself.

Features of installation and operation

Polyethylene pipelines are installed according to standard schemes, with the exception of small nuances:

- The pipes are brought into the room for 2–3 hours so that they warm up to room temperature.

- It is advisable to cover pipe lines made of cross-linked polyethylene with protective boxes or place them in niches to avoid accidental mechanical damage.

- Niches and boxes must have a margin in size, since pipes made of cross-linked polyethylene expand when heated.

- Detachable fittings cannot be embedded in walls or concrete floor screed; they must be easily accessible for maintenance.

- The bending area is first heated with a hair dryer, then the workpiece is placed in a mandrel made of boards, plywood or other available materials until it cools completely.

- Burrs must be removed from the ends of the cut parts, as they can clog the pipeline.

- To fix the wiring to the walls, special fasteners are used - clips held by dowels.