Some of the most famous manufacturers of cross-linked polyethylene at the moment are German and Italian. Rehau offers its customers pipes with a diameter of 12 -63 mm. VALTEC has a more modest range - pipes with a diameter of 16 and 20 mm. But this is quite enough for standard solutions of communication systems. All products of these companies have the necessary certificates confirming the required quality in accordance with European standards and Russian GOSTs. VALTEC pipes belong to class 4 according to GOST R 53630, and the Rehau cross-linked polyethylene pipe is developed in accordance with GOST and DVGW (DW-8501 AU2346).

What does a cross-linked polyethylene pipe look like?

Worth knowing! Due to its simple installation, the price of cross-linked polypropylene pipes is approximately 20-30% more profitable than metal-plastic analogues.

PEX Pipe Composition

This type of pipe is a five-layer structure. The hidden (first) layer and the outer (last) layer are cross-linked polyethylene, the second layer is an adhesive base, the third layer is an oxygen barrier, the fourth layer is an adhesive base.

Crosslinking methods for PEX pipes:

- physical cross-linking - irradiation with x-rays (radiation method). The product material sewn in this way is marked PEX C;

- silane crosslinking method - immersion in a chemical solution. The stitching process occurs from the outer and inner balls inwards, i.e. The inner and outer balls of the plumbing have stronger stitching than the middle of the wall. Marking – PEX B. Differs from plumbing fixtures with other markings due to the higher pressure coefficient;

- chemical process under high pressure with laser beam treatment (peroxide method). Marking – PEX A. The product is flexible and plastic, but it is inferior in terms of pressure;

- nitrogen method - nitrogen acts as a catalyst. Marking – PEXD.

Manufacturer Valtec

Valtec PEX Evoh pipe is molecularly cross-linked polyethylene. Pipe connections made of polyethylene have low heat resistance and are therefore not suitable for use in heating systems. Molecular cross-linked polyethylene has transferable bonds, which makes it more durable, and most importantly, extremely resistant to temperatures not exceeding 90 degrees. Cross-linking of polyethylene at the molecular level is based on 3 main methods:

- Proxy method. Organic peroxides + hydroperoxides, and the maximum crosslinking is about 75%.

- The molecular silane cross-linking technique occurs using organosilanides. The minimum degree of crosslinking is 65%.

- The radiation crosslinking technique is performed using a stream of charged particles, with a crosslinking degree of about 60%.

Valtec pipelines are cross-linked using the silane method, which guarantees its strength (about 70%). Also, quite important is the fact that this level of firmware allows you to “remember” and restore the original shape of the product, which means that kinks in this pipe are not dangerous. The process of restoring the original shape occurs due to internal stress resulting from heating.

PEX Evoh cross-linked polyethylene pipe is very easy to use and install. Without resorting to preheating, the required drainage area can be bent within a radius of five of its own diameters. If you need a bend of a smaller radius, pre-heating is required using a hair dryer (without breaking the material). By purchasing Valtec, you can be sure that you will be able to connect them with other similar components, since metal-polymer pipelines have a standard wall thickness of 16 x 2.0, which makes it possible to use much-needed fittings and couplings by pre-ordering them on the Rosterm website .

The PEX polymer pipe with an anti-diffusion layer from the manufacturer Valtec has a three-layer design, and the anti-diffusion layer itself is located on the outside. Repeated studies and tests have shown that PEX-glue-EVOH pipe is more practical and reliable than five-layer (PEX-glue-EVOH-glue-PEX).

The fact that a three-layer water supply system is many times more reliable than a five-layer one can be explained quite simply: in a three-layer one, the PEX ball is applied in one single and continuous layer, which is not the case in a five-layer one, since the same ball is interrupted by a layer of EVOH and glue. Due to the above factors, with a five-layer water supply there is a risk of ball delamination, which can occur during forced heating. There is an opinion that the EVOH layer can crumble and wear off, but many experts refute this opinion, since the PEX layer is softer and more susceptible to external physical influences.

Underfloor heating system

The underfloor heating system requires special consideration, because in recent years it has become very popular and relevant. The many positive reviews about the “warm floor” pipeline system speaks for itself. The previously used copper pipes have become obsolete, and the PEX Evoh floor heating pipe has taken one of the leading roles in construction and installation work.

The anti-diffusion layer in pipes of this type is located in the core of the product, which allows you not to worry about its possible damage, and makes it possible to cover the pipeline with concrete screed, marble or tiles. The following qualities should be noted in the “warm floor” system:

- The heat in the room is distributed evenly over the entire floor area;

- For him, it makes no difference what energy source he works on - it can be an oil boiler or central heating;

- Does not pose any harm to human health;

- Energy savings, which are generated due to optimal heat transfer;

- The installed thermostat makes all processes automated;

- Easy to install and does not require bulky equipment.

For an underfloor heating system there is no limit to the volume of installation - it can be either a small coil in the bathroom or a warehouse with a huge square footage. To give you an idea of what installing a heated floor looks like, we have specially prepared several photos.

A system similar to underfloor heating is increasingly used to heat open surfaces - concert venues, sidewalks, shopping pavilions, etc. A constant positive temperature (0 - +5) will help you forget about wetness, dirt and slush. Ease of use and the absence of the need to hire additional workers (for example, to clear snow) completely compensate for all the costs of both the material itself and its installation.

Scope of application of cross-linked polyethylene pipes

Pipes made of cross-linked polyethylene for heating can be operated at high temperatures (up to 95°C, and with short-term exposure - above 100°C) without being subject to deformation. The melting point of the products is 200°C, the combustion temperature is 400°C. The number one material for installing heated floors and heating systems. Valtec products will give your home warmth and comfort.

Beware of counterfeit products. The product must be marked on the outside. Mandatory to indicate: stitching method; date of manufacture; wall thickness and diameter; operational indicators; quality checking.

Products manufactured using the listed methods can be used for laying drinking and process water, sewerage, supplying compressed air and chemical compounds.

Products can be used for up to 50 years. They vary in diameter (from 10 to 200 mm). The most popular pipes are with a diameter of 16-25 mm.

What is cross-linked polyethylene?

Why choose cross-linked polyethylene?

Cross-linked polyethylene pipe is a modern generation building material. The origins of its creation lie in the last century. It was then that the first PEX - cross-linked polyethylene - was produced. But today this material has a completely new image, with many advantages and possibilities.

The basis of cross-linked polyethylene is its processing under high pressure and the creation of special bridges between the layers. This process is called “stitching”. Hence the name of the material itself - Rehau pipes made of cross-linked polyethylene.

There are several pipe stitching technologies:

- Peroxide technology (PEXa).

- Gas treatment (PEXb).

- Creation of an electromagnetic field and irradiation of a material with electrons (PEXc).

- Treatment thanks to nitrogen compound (PEXd).

For example, Valtec cross-linked polyethylene pipe is created using PEXb technology, and Rehau products are created using PEXa and PEXc technology.

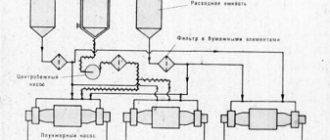

Diagram of a polyethylene cross-linked pipe

The choice of pipe largely depends on the production method. For operation at high temperatures, PEXa is preferred, while PEXc is low cost and ideal for operation at low temperatures.

Where is cross-linked polyethylene used?

Cross-linked polyethylene technology is used in the arrangement of hot and cold water supply, as well as for heating systems in homes, offices and apartments. Rehau polyethylene pipes are also used to install warm water floors. In this case, the home owner does not have to worry about the integrity of the pipe even at high temperatures.

Rehau products can significantly increase the service life of the communication system. During production, this material is deprived of its crystalline form, which makes it flexible and practical. With it you can create heat and water supply systems with a large number of bends.

The service life of pipes depends on the operating temperature. At temperatures up to 75º and pressure up to 9 bar, Rehau polyethylene pipes will last up to 50 years. If the operating temperature in the pipes reaches 95 º, then the service life is reduced to 15 years. Rehau polyethylene pipes tolerate low temperatures more easily due to the existence of cross-links. But a Valtec cross-linked polyethylene pipe can be operated at a temperature of no more than 80 º and a pressure of 6 bar. Raising the temperature to 95 º is possible only for short periods. In this case, the estimated service life is 50 years.

Warm wall system made of cross-linked polypropylene

Advantages of the material

The advantages of this material are as follows:

- Reliability and long service life.

- Resistance to chemical processes, including oxidation.

- The presence of a diffusion barrier, which avoids the penetration of oxygen from outside.

- High resistance to hydrodynamic and mechanical pressure.

- There are practically no cracks on the surface of the pipes.

- Stable operation at high and low temperatures from -200 to +200°.

- The ability to recover, i.e., to acquire previous performance when receiving damage in the form of deformation.

- Absence of manifestations of the corrosion process - the appearance of rust on the surface of the pipes.

- High shrinkage rates.

- No release of harmful substances even when working at high temperatures.

- Absence of heavy metals.

- Saving time during installation.

- Affordable cost of material.

Pipe Valtec PEX-EVOH 16×2.0

Valtec Pex-Evoh polymer pipes 16 mm X 2.0 mm are used in modern water supply and heating systems. Their special feature is their unique design, which ensures strength and reliability. To produce such pipes, specialists from an Italian company use cross-linked polyethylene, which has a fairly high density. It is made from polyethylene using PEX (B-Monosil) silane cross-linking technology. It significantly increases the strength and resistance of pipes to high temperatures. Their top layer is made of a special material Evoh (ethylene vinylol). It protects the coolant from the penetration of oxygen molecules. High-quality and durable Valtec Pex-Evoh pipe 16 mm X 2.0 mm is suitable for use in water supply systems, including drinking water. In heating systems, they can only be used if the operating temperature of the coolant does not exceed 80°C. Pipes of this series fully comply with high quality standards and can be used in underfloor heating systems. Thanks to the use of high-tech equipment and innovative materials, such pipes are distinguished by impeccable quality, reliability and functionality.

Modern Valtec Pex-Evoh pipes 16 mm X 2.0 mm have a number of significant advantages that ensure their durability. They are characterized by low hydraulic resistance and can withstand high pressure. Their inner layer is resistant to corrosion and alkali. They do not emit substances harmful to the human body even at high coolant temperatures. They perfectly absorb noise and are electrically inert. Able to withstand fairly low temperatures without destroying the inner layer. Valtec Pex-Evoh pipe 16 mm X 2.0 mm is supplied in special coils of different sizes. Its installation is quite easy using special press fittings from the Italian company Valtec. Such pipes are quite flexible, which also ensures ease and convenience during installation. However, they are not protected from ultraviolet rays, so it is recommended to use them only for interior work. Italian brand pipes of this series fully comply with international quality standards, as they are produced in accordance with GOST and have a high 4th class of operation. Their use in various heating systems of residential buildings and commercial premises is allowed.