Hello, dear guest.

Today I propose to pay attention to the profile pipe. The same one from which greenhouses, furniture, fences, house frames and a bunch of other necessary and important structures are made. Steel profile pipes are very common in our lives. We encounter them every day and do not pay the slightest attention to them.

But in vain. Therefore, the production of profile pipes is a real gold mine even for a novice entrepreneur. The initial capital can be increased significantly, and in the shortest possible time.

Therefore, in today’s article we will take a detailed look at all the technological stages of profile production and learn how to organize pipe production on a small “home” scale.

And also, exclusively for visitors to our site, I will reveal some secrets of making a profit that you will not find in other sources.

So, make yourself comfortable - we're starting.

Technology

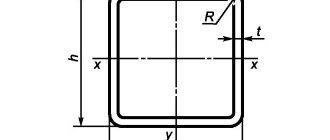

Profile pipes have a square or rectangular cross-section with side sizes from 15 to 300 mm. Due to the wide range of sizes, they are used in almost all sectors of construction and economics. They are several times lighter than a solid metal rod and much more economical.

The production of profile products is more difficult than round ones. Initially, you should prepare a semi-finished product in the form of a metal strip (strip), then a round profile is formed from it on a special machine. A rectangular or square product is formed from the resulting workpiece using rolling.

Strip processing

Strip is a metal strip made of low-alloy or carbon steel. Supplied to production in rolls. It is produced by longitudinal cutting of rolled steel sheets on special rolling mills.

Initially, the strip is much wider than the required blank for the pipe. The production line includes equipment for cutting the tape to length. The result is stripes with a width of 50mm.

The metal strips obtained after cutting are welded and wound onto a constantly rotating drum.

Important! The thickness of the strip determines the wall thickness of the finished product.

Round Pipe Forming and Welding

The next stage is feeding the metal strip to the machine to produce the workpiece. On the mill, a billet with a round cross-section is formed using rollers in several stands. Typically this stage occurs without heat treatment.

After the section is formed, the workpiece is transferred to a welding installation, where its free edges are welded using high-frequency currents. At the same time, the pressure of the rollers continues and promotes the removal of excess metal (burr). The burr is removed using cutters installed on the mill. After welding, the workpieces are cooled with special emulsions.

Important! Most profile pipes are electric welded. An electric-welded pipe differs from a seamless pipe in the presence of a weld seam.

Profiling

During the cooling process with emulsion solutions, the round billet is fed to the next rollers - calibration rollers. They make it even along its entire length.

At the next stage - the next special rollers, crimping. It is they who, squeezing the workpiece from four sides, form the finished product. After this, the pipe is cut into the required lengths.

Control

The weak point of any electric welded pipe is the seam. Therefore, before allowing a profile for sale, it is necessary to evaluate its quality.

Quality control of finished products is carried out using the following methods:

- Eddy current flaw detection.

In this method, eddy currents are recorded by a receiving meter. Their intensity determines the presence of voids, cavities and other defects in the metal.

- Visual inspection

An inspection specialist (he must have confirmed high qualifications) inspects the pipe and identifies all external defects - cracks, unwanted marks of profiling rollers, welding defects, mechanical damage.

Ideally, both of these methods are used in parallel, but in a production facility with a large volume of products you cannot inspect every pipe, so it is necessary to systematically carry out mandatory preventive maintenance of all equipment in the workshop...

Heat treatment

To increase the strength and durability of the product, steel must be hardened. Therefore, the finished pipe undergoes mandatory heat treatment. In this case, all internal stresses arising during the deformation of steel are “released”.

Hardened products have a higher cost, so not every mini-factory practices this process.

What is a profile pipe?

This is the name of shaped metal products made from metal sheets or blanks. For this, different types of steel are used:

- carbon (St3);

- low-alloy structural;

- special steels characterized by improved properties: heat and chemical resistant;

- stainless.

Other materials are also used: aluminum and alloys based on it, copper, brass. Such products can have an oval, flat-oval, rectangular or square cross-section. At one stage of production, a round billet is formed, but then it passes through the rolls of a rolling machine, acquiring the desired shape. If such a need arises, a triangular or polygonal pipe is made, but this is only possible on an individual order.

Products are divided into types, differing in the production method and properties of the finished products:

- cold-rolled profile pipes;

- hot-rolled seamless products;

- cold rolled electric welded products.

The first option is often used because it is durable and characterized by sufficient elasticity, which allows it to withstand deformation loads (tensile, compression). Hot-rolled seamless products are also durable. They are installed in areas with high loads. Additionally, the resistance of such products to the negative effects of aggressive substances and corrosion is noted.

Electric welded pipes are produced by welding a workpiece. Such products are durable, despite the presence of a seam connection. Modern technologies make it possible to obtain high quality products that will serve for a long period. After the pipes are manufactured, the strength of the seam joints is assessed. Scope of use of such products:

- construction of objects based on metal structures;

- production of greenhouses, canopies;

- setting up a production line for commercial equipment;

- fencing;

- furniture industry;

- laying a gas pipeline (for copper products);

- industry;

- agriculture, etc.

Equipment and equipment of the workshop. Line composition

Ready-made factory lines include several units. Depending on the required number of output products, the power and productivity of each pipe production machine may be different, but the operating principle remains the same. Let's consider the full production cycle step by step.

Unwinder

The apparatus necessary for unwinding the strip. The most common is console. The cantilever decoiler is available with manual and automatic blade expansion drives, weighing from 300 kg to 4 tons.

Rolling mill. Types and principle of operation

The following types of rolling mills are found in modern production shops:

- Single-roll bending machine

Used to shape sheet metal. Such equipment is used to create simple profiles - gutters, ebbs, consoles.

- Three roller machine

This technique is used to form tubular products and rolled profiles. The power of the device depends on the clamping mechanism. If the force generator is a regular clamp connected to a pressure roller, the productivity of the unit will be extremely low. To increase the force, replace the clamp with a hydraulic drive.

- Four roller machine

The four-roll machine is equipped only with a mechanical drive. It has the ability to form a profile of any section. It features increased energy consumption and is used in serial enterprises.

Cutting device

After rolling, the profile product goes to the cutting device.

There are three types of cutting devices.

- Band saw machine

Cuts using a saw made of high-speed steel in the form of a closed band. They are mainly used in large enterprises.

- Hacksaw machine

Here the cutting tool is a saw blade mounted in a frame. There are manual and electromechanical options. Compact, simple and reliable. Common in small industries.

- Device with cutting disc

The most popular unit with a circular saw as a cutting tool. They are characterized by simplicity and low energy consumption. Most often used in small production workshops.

Receiving device with roller conveyor

A roller conveyor is necessary for transporting finished profile pipes to the storage location (in the so-called “pockets”). A standard receiving device with a roller conveyor includes a drive section, a frame with idle rollers, and a mechanism for dropping pipes into pockets.

The drive section supports the pipe and sets it in motion; a frame with rollers moves the pipe along the roller conveyor to the dropping mechanism. The release mechanism sends the product into the pockets.

Auto control system

The automatic control system allows you to control the rolling speed, regulate the length and number of products and regulate pauses in the production cycle.

Equipped with a control panel with an indication system of basic parameters and, ideally, an emergency warning signal.

Requirements for premises and personnel

For small batch production it will be enough:

- Area of at least 4×18m;

- Lifting equipment - at least 5 tons;

- Service personnel - at least 1 operator and 1 assistant;

- The service life of equipment for the production of profile pipes must be at least 10 years.

Important! For the production of large-sized pipes, it is necessary to select units with increased power.

Business financial plan

Even in a mini-shop, it is possible to produce 15 meters of profile pipe per minute. And the enterprise’s income also depends on what size this pipe will be. With an average cost of a small pipe of 15 rubles per meter, its price on the market is twice that. Now it is about 30 rubles per meter of production. Already from one linear meter of a profile pipe, a profit of 15 rubles is obtained. If the sales channels of goods at the enterprise are well established, then in a month of work you can increase the revenue from the sale of finished products to 4 million rubles. It is difficult to imagine higher rates of profitability and profitability of modern business.

Excellent business profitability can be achieved by purchasing pipe manufacturing equipment that has even low power. Some entrepreneurs, without having significant start-up capital, begin to earn money by making a profile pipe with their own hands. In this case, the simplest equipment is required; the price of a machine for individual manual work does not exceed 200 thousand rubles. Considering that the demand for products is currently only increasing, even in such a small version of organizing your own business you can make a good profit.

Over time, having studied the intricacies of the market for the sale of finished products and the supply of sheet steel raw materials, you can move on to the production of galvanized profile pipes. The price for these products is significantly higher than for pipes made of black and white steel. Attracting more and more customers to his product, each businessman gradually enlarges his profitable business and begins to master the production of building materials of related design.

Who to sell the pipe to

Profile pipe is used everywhere. Therefore, the pipe sales market is huge.

The product is used in the following areas:

- Building frames (including popular low-rise frame construction);

- Construction of bridges;

- Construction of building trusses;

- Mechanical engineering;

- Furniture manufacture;

- Advertising;

- Partitions;

- Metal hangars.

And this is not a complete list of activities.

All organizations specializing in any activity from the list purchase a profile pipe and can become your clients.

Sales of finished products

In order for the costs of a mini plant for the production of profile pipes to pay off as quickly as possible, even before launching the workshop, you need to think about how and to whom you will sell the finished product. The ideal option is to find and establish cooperation with several wholesale buyers. This way the line will be fully loaded, and you won’t have to worry about how to sell the pipes. It may be difficult to find large buyers. Therefore, get ready for the fact that at first you will sell most of your products to small construction companies and private individuals. This is a common practice for new businessmen. Be sure to allocate some part of your budget for an advertising campaign. Do not underestimate the role of advertising for a new business. The following sites are perfect:

- Own website. Here you can tell your customers about what kind of profile pipe production line you have in your workshop, describe the advantages of your particular product, indicate contact details and prices.

- Advertisements in the media and specialized catalogues. This way you have a chance to interest wholesale customers.

- Leaflets. Also a good option, more designed for individual buyers.