Three types of shut-off and control valves can be used on radiators - shut-off, tuning and regulating a specific device. But why can’t you reduce the cost and use one of the cheapest ball valves, or not use them at all…. How and why the piping is done, which taps to choose correctly for radiators so that the heating system works stably and for a long time...

Ball valves for shut-off

At a minimum, ball shut-off valves should be installed on radiators so that the device can be repaired without draining/stopping the heating system in winter. But ball valves cannot be used for adjustment. If only because it is not possible to make precise adjustments - at 7% of the rotation angle of 90 degrees there is an adjustment range of 85% of the flow.

The valve should not be in intermediate positions at all, since it is worn out by very quickly moving abrasive, cavitation bubbles, and pressing with a piece of wood also occurs, without the possibility of turning. Therefore, it is not recommended to use this unit in any way other than for its intended purpose - opened/closed.

Ball valve for shut-off only

Adjustment valves

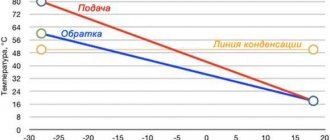

Designed to balance the entire heating system, and not to adjust the specific radiator on the return line of which they are installed. Quite often, it is necessary to first increase the hydraulic resistance for some radiators so that the coolant is distributed evenly across the heating devices.

For example, in a dead-end circuit with up to 4 radiators, balancing is usually not required and such a valve may not be installed. But with 5 radiators, it is desirable to increase the flow resistance on the first one so that the last one is not cold. And at 6, balancing is already needed on the first three radiators... In reality, the intricacies of pipes from experienced installers can be the most intricate, so they use the settings.

Adjustment on radiators

There are two types of control valves for radiators - manual and automatic, controlled by a thermal head or a servo. They serve as adjustments to quickly configure a specific radiator according to the user’s wishes. “I wanted it cooler - I went up and turned it off...”

Thermal heads control pressure control valves depending on the air temperature - a popular option for equipping batteries. But automation cannot be used in conjunction with solid fuel boilers without a heat accumulator.

Control taps and savings

The control valve is most useful because of the opportunity to save significantly. You can make secondary rooms cold and this gives up to 30% savings on heating in the house per season. If there is programmable automation (electronic thermal heads or a processor with servo drives), then you can set the “day-night” mode in such a way that the house warms up only in the evening, when the occupants are at home, and during the night it cools down and is cold during the day... But this saving, according to the European model, is quite impressive.

What taps to equip a radiator with?

- With extreme savings, they don’t install taps on radiators at all, hoping “at chance.”

- The minimum set is two ball disconnect devices.

- The usual option is a ball on the return and manual adjustment on the feed. You can adjust the device as desired and, if necessary, keep the adjustment as balancing.

- Adjustment - balancing on the return and adjustment on the supply - is used where it is necessary to balance a specific radiator.

- Automatic operation - there is automated adjustment on the supply, while the return may have a ball valve or balancing.

When the pipes are under the floor - bottom connection

Radiators with bottom connections are increasingly being used, and pipes are hidden under the floor. In this case, a radial wiring diagram from one collector is often used. In this case, the shut-off and control valves are installed on it, and a couple of tubes rise to the radiator and that’s it. But if balancing/adjustment is needed, manufacturers offer a connecting kit.

Diagram of the usual connection of radiators with bottom wiring in a radial system

It is also not uncommon for radiators with side connections to be used for underground wiring. Manufacturers also took care and supply heating devices with a set of “adjustment-balancing” valves, between which a jumper is installed to power the supply.

The heating system often includes control mechanisms and mechanisms that ensure safe operation. They are otherwise called heating system valves. With the help of these adjustment elements, the heat supply parameters change; they also ensure stable operation and perform automatic adjustment. Let's look at the valves and regulators of the heating system, since their purposes and functions differ.

Three way heating valve

Typically, boiler automation cannot meet the need for water at different temperatures for several circuits of the heating system. A three-way thermostatic mixing valve of the heating system comes to the rescue, which maintains the necessary thermal parameters of the coolant in the circuits of the heating system, as well as in the small circuit of the system. The valve looks like a simple tee, the metal is bronze or brass. An adjusting washer is installed at the top of this tee, under which there is material sensitive to temperature changes. And if necessary, it presses on the working rod coming out of the housing. The main task of the valve is based on maintaining the temperature of the coolant at the outlet within specified limits by adding cold or hot water . During unsuitable temperature changes, the external valve actuator presses on the stem. Next, the cone leaves the saddle and a passage opens between all channels. During operation, the three-way valve is controlled according to temperature by an external actuator.

—

CONDITION 1

RESULTS ROOM ¸ÐºÐ°Ð¼Ð ¸ regurgitation ÑелÑкой. â

RESULTS ºÑÐ°Ð½Ñ ÑÑÑанавливаÑÑ Ñ Ð½Ð°Ð³ÑеваÑелÑнÑÑ Ð¿ÑибоÑоР²Ñи ÑÑем оÑоплениÑ; RESULTS ¾Ð´Ñ, поÑÑпаÑÑей в нагÑеваÑелÑнÑй п ÑибоÑ. â

| RESULTS. â |

RESEARCH, RESULTS ASSESSMENT I'm sorry. RESPONSIBILITY, RESPONSIBILITY ¿Ð¾Ð»Ð¾Ð¶ÐµÐ½ близко к ÑÑоÑÐºÑ Ð¸ Ñоеди → ´Ð¸Ð°Ð¼ÐµÑÑа, ÑÑо ÑаÑе вÑего вÑÑÑÑеÑаеÑÑÑÑ Ð¿°Ñи Ð¾Ð´Ð½Ð¾Ñ ÑÑбной Ñи ASSURANCE, ASSURANCE, CONTROL ±Ð¾Ñом и ÑÑоÑком ÑеÑез обÑаÑнÑÑ Ð¿Ð¾Ð´Ð²Ð¾Ð´ÐºÑ Ð¿ÑÐ ¾ RESULTS RESULTS , , , , , , , , , , , ²ÑаÑаеÑÑÑ Ð² ÑÑоÑк по ниР¶Ð½ÐµÐ¹ ÑаÑÑи подводки. â

Ðñ ° ðory ð´²²ð¹ð¹ð½^ ñ ñµices ”ðñ½ºð (ð¿ñuthently ( " registry ¾Ð±ÑаÑной) ÑоглаÑно пÑоекÑÑ. RESULTS RESULTS ¾Ð²ÐºÐ¸ пÑи RESULTS with the ÑоÑодР°. â

| RESULTS . â |

RESULTS RESULTS Ñ Ð ¿Ð¾ диамеÑÑам в ÑÑÑÐºÐ°Ñ Ñ Ð¿Ð¾Ð´Ñазделением на RESULTS. â

| RESULTS ÑлиÑовки ной ÑегÑлиÑовки. â |

RESULTS 100 Ð ¡. 100 rubles. â

| RESPONSIBILITY. â |

RESEARCH (No. 132, No.) A Ð¾Ð¿Ð»ÐµÐ½Ð¸Ñ . â

| ROSS-READY.| RESULTS. â |

RESULTS RESULTS Ñи гоÑÑÑей Ð²Ð¾Ð´Ñ Ð² нагÑеваÑелÑнÑе пÑибоÑÑ. â

RESULTS Ñ Ð´Ð»Ñ ÑиÑÑем Ð²Ð¾Ð´Ñ Ð½Ð¾Ð³Ð¾ оÑоплениÑ. â

RESULTS RESEARCH, RESEARCH, RESEARCH ¸Ð»Ð¾, подводÑÑей к нагÑеваÑелÑнÑм пÑибР¾Ñам ÑÑÑбе. RESULTS RESULTS ¾Ð²ÐºÐ¸ пÑи RESULTS Ñ ÑÑÑанавливÑÑÑÑÑ Ñ Ñ Ð¿Ð¾Ð»Ð½Ð¾ÑÑÑÑÑ Ð¾ÑкÑÑÑÑм ÑеÑение м пÑоÑоР´Ð°. â

Heating check valve

A complex heating system contains a fairly large number of auxiliary elements, the task of which is to ensure reliability and uninterrupted operation. One of these elements is the heating system check valve. A check valve is installed to prevent flow in the opposite direction . Its elements have very high hydraulic resistance. Due to this circumstance, there are restrictions on the use of check valves in a heating system with natural circulation. There is too little pressure in such a system. At minimum pressure, it is necessary to install gravity valves with a butterfly valve; some of them can operate at a pressure of 0.001 bar. The main part of the check valve is the spring, used in almost all models. It is the spring that closes the shutter when normal parameters change. This is the principle of operation of a check valve.

It is necessary to take into account the operating parameters in a particular heating system. Therefore, select a heating system valve that has the required spring elasticity. Shut-off valves used in heating systems are usually made of the following materials: steel; brass; stainless steel; gray cast iron. Check valves are divided into the following types: disc valves; petal; ball; bivalve. These types of valves are distinguished by a locking device.

Criterias of choice

When deciding which taps are best to install on heating radiators, the following series of criteria must be taken into account:

- Type of heating system, its operating characteristics - temperature, pressure, coolant used and its chemical properties.

- Functionality, purpose, type, properties and quality of the material of the tap itself.

- The method of activation is manually, automatically using sensors and a controller, or semi-automatically.

- Technical parameters of the valves - maximum permissible pressure, operating temperature, etc.

- Corresponding to the diameter of the system pipes.

- Type of connection, thread location (external or internal), pitch.

Heating control (shut-off and control) valves

Regulating and shut-off and control heating valves systematically change the flow of coolant, from maximum to minimum , with the valve open and closed. Shut-off or shut-off valves control the coolant discretely when the valve is in the fully open or fully closed position. A control valve consists of three main blocks: the body, the throttle assembly, and the valve actuator. The closing and regulating element of the valve is the throttle assembly. When choosing a sleeve, seat, or plunger, you should pay attention to the operating conditions of the valve. The medium and its temperature, the presence of impurities, and throughput are taken into account. The main and important importance in the operation of the valve is the correct direction of supply of the working medium. It is usually marked with an arrow on the working surface of the case.

Installation of ball valves on batteries

A conventional ball valve is designed only to switch to 2 positions: “open” and “closed”. It cannot be used to regulate the flow of coolant through the radiator, only shut it off. The figure below shows a simple connection diagram for a heating device with this type of fittings:

The proposed scheme is the best option for an unregulated connection of a radiator to the central heating risers in an apartment. You won’t have to balance it anyway, and installing a thermostatic valve is pointless due to the poor quality of the coolant. Instead of a ball valve at the outlet, it is also practiced to install a so-called shut-off valve; its difference is only in appearance.

Depending on the layout of appliances and heating pipes, you can choose an angle valve for a radiator with or without a decorative coating

Also, when choosing a product, it is recommended to pay attention to the operating pressure indicated on the product body or in its passport. It must correspond to the pressure in the heating network of the apartment building

Advice. For installation on the radiator, choose good taps made of thick-walled brass and a connection with an American union nut. It will allow you to quickly disconnect the connections without rotating the elements. On a single-pipe riser, do not forget to install the bypass with a slight offset away from the main pipe.

Thermostatic valve

In modern realities, a thermostatic valve is a prerequisite for modern and reliable equipment in a heating system. The valve temperature is automatically adjusted. The operation of a heating system mixing valve for radiators is to limit the supply level to an individual heating radiator. The valve stem makes movements to open and close the hole. Through this hole, coolant enters the radiator. When the valve with a thermostatic head heats up, the inlet opening is closed, as a result of which the coolant flow rate decreases. The thermostatic valve constantly changes its position. And an important factor is the quality of the materials on which this product is made. The product may fail due to sticking of the rod, as well as significant corrosion and breakthrough of sealing materials. But even if the thermostatic valve fails, you can extend its service life by replacing the thermostatic element.

Heating system valves with thermal heads differ depending on the shape and type of supply to the heating system. They can be angular when connected to radiators from the floor, or they can be straight, which connect the pipes to the battery relative to the wall surface. Axial, mainly when connecting pipes from the wall to the battery. When connecting batteries sideways, a special kit is required. It uses thermostatic heads and valves. Batteries that come with a bottom connection are obviously equipped with valve-type inserts.

Options for organizing the supply and removal of coolant to radiators

When installing heating systems, two main wirings are used: with one or two pipes; a combined supply of free-standing heat exchangers is often practiced. In many cases, the connection points for radiators are their two pipes located on the sides; modifications with two lower outlets are similarly connected when installed using special N-shaped bottom connection units (binoculars).

Fig. 5 Top supply in an apartment building - traffic diagram

Single pipe system

This wiring has become widespread in public utilities and everyday life due to its following advantages and features:

- The option with one pipe is the most profitable from a financial point of view, allowing you to save materials twice as much as compared to a two-pipe one.

- In addition to saving materials, the complexity of installation is reduced and, accordingly, the cost of arranging a single-pipe distribution is reduced - fewer grooves are made in the walls, a relatively small number of different types of fittings are purchased: bends, tees, shut-off and control valves, couplings, the work on assembling the pipeline is accelerated by soldering, press or compression fittings.

- In a line with one pipe, the coolant moves sequentially along the entire chain of radiators, with the first one, closest to the heating boiler or heating network, having the highest heat transfer, and the last one being the coldest.

Pressure regulator

The operation of the batteries and the pump is disrupted due to high or low pressure levels. Correct control of the heating system will help to avoid this negative factor. The pressure in the system plays a significant role, it ensures that water gets into the pipes and radiators. Heat loss will be reduced if the pressure is standard and maintained. This is where water pressure regulators come to the rescue. Their mission is primarily to protect the system from too much pressure . The operating principle of this device is based on the fact that the heating system valve located in the regulator works as a force equalizer. Depending on the type of pressure, regulators are classified into: statistical, dynamic. It is necessary to select a pressure regulator based on throughput. This is the ability to pass the required volume of coolant, in the presence of the required constant pressure drop.

Varieties

In modern private houses, the following 4 types of shut-off and control valves are used for radiators:

- Ball overlapping.

- Regulator valves.

- Thermostat valves.

- Air removal mechanisms.

Let us examine in detail their structure, scope of application and operating features.

Ball

Ball valves for heating are classified as shut-off valves. They function only in opposite positions - open or closed. With their help, it is impossible to reduce or increase the coolant flow - but only to completely open or shut off. Therefore, their main area of application is a place where, if necessary, you need to quickly stop the water supply, for example, in front of a battery - when it needs to be replaced or repaired, and also in the event of a leak - the device will quickly shut off the flow.

Ball valve Source aqua-therm.org

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

The design of the mechanism is based on a steel ball with a through hole. It is connected directly to the handle. In the open position, coolant flows through it. When the handle is turned at a right angle, the spherical element also turns 90 ° and completely stops the flow.

Ball valves are classified according to the following characteristics:

- Type of material. As a rule, the body is made of brass, as well as silumin alloy or plastic.

- Changing the direction of flow - straight and angular.

- Throughput indicator. In its standard form, its value does not exceed 0.8, in full-bore specimens – 1.

- Recommended network pressure parameters.

- Connection method: coupling, welded, flange.

Advice! For connection to radiators in a private house, mainly those with a coupling connection are used. Flange models have a greater safety margin and are suitable for installation on centralized pipelines.

Typical radiator tap Source sopytka.ru

Balancing valves

The heating control valve is equipped with a valve connected to a cone-shaped threaded rod. The smooth movement of the valve ensures a gradual increase or decrease in flow. Using it, it is possible to manually adjust the required flow and pressure in a given section of the heating system. Often such a mechanism is mounted at the outlet of the battery.

The material used for their manufacture is brass or bronze alloy. Budget models are often made from polypropylene. However, it is better to install such taps on pipes of a similar composition. With respect to the direction of flow, they can be either straight or angular. They are used for rough adjustment of the heating level of radiators in various parts of the heating system.

Valves for thermoregulation

An automatic thermostatic valve for a heating radiator is today’s best option for a mechanism for controlling energy consumption in a private heating system. The principle of its operation is based on the compression-expansion of a special gas or liquid in a container connected by a piston to a closing device in the tap.

Tap for automatic control of battery heating Source gopb.ru

Heating bypass valve

To relieve the working medium, use the bypass valve of the heating system thermostat, which operates in the return direction when the pressure increases significantly . As a rule, the pressure increases due to the achievement of the maximum temperature set manually, the supply of coolant to the radiator decreases, as a result of which the pressure increases. Heating system bypass valves are basically designed to ensure a stable difference between the return and supply pipes. When the heat load decreases, the thermostatic valves close, resulting in a pressure difference between the pipelines. As a result of using a bypass valve, the load on the pump is reduced, the return temperature increases, and the boiler is protected from corrosion. The scope of application of the heating system bypass valve is quite wide; it is also used to prevent noise generation of thermostats. Bypass valves are installed not only on an unregulated pump, but also on riser jumpers.

Air valves and radiator fittings

Almost all modern radiators provide the possibility of installing Mayevsky manual valves for air discharge. Some manufacturers even complete their products with them. If desired, instead of a manual air vent, you can install an automatic one, but in practice it does not look very presentable.

Recently, laying heating lines below floor level and using radiators with bottom connections has become increasingly popular. Then there remains a small gap between the battery and the floor, where it is not always possible to place any fittings. For this case, there is a special connection headset with built-in taps, shown in the picture (left):

On the right is a headset for the bottom connection of a conventional radiator with side plugs; it also has valves plus the ability to connect a thermal head. Such solutions look very aesthetically pleasing, but will require maximum financial costs. More information about the headset is shown in the video:

Safety valves

Any boiler equipment is a source of danger. Boilers are considered explosive because they have a water jacket, i.e. pressure vessel. One of the most reliable and widespread safety devices that reduces the danger to a minimum is the safety valve of the heating system. The installation of this device is due to the protection of heating systems from excess pressure . Often this pressure occurs as a result of boiling water in the boiler. The safety valve is installed on the supply pipe, as close to the boiler as possible. The valve has a fairly simple design. The body is made of good quality brass. The main working element of the valve is the spring. The spring, in turn, acts on the membrane, which closes the passage to the outside. The membrane is made of polymer materials, the spring is made of steel. When choosing a safety valve, it should be taken into account that full opening occurs when the pressure in the heating system increases above the value by 10%, and full closure occurs when the pressure drops below the response value by 20%. Due to these characteristics, it is necessary to select a valve with a response pressure higher than 20-30% of the actual one.

Why is a pipeline buried?

Backfilling of the pipeline is carried out after the final installation of the water supply system. Such backfilling is carried out in order to hold the laid pipes in a stationary position.

Fixing pipes with backfill is carried out in several stages.

- Manual filling with shovels. This is the initial stage. It is carried out on both sides.

- Backfilling after compacting and joining pipe joints.

- Sprinkling of pipes. This is also done on both sides.

Balancing valve

The balancing valve of the heating system is intended to regulate the coolant passing through . Liquid consumption depends on pressure. The higher the pressure, the more fluid is consumed. This device is installed on risers. A balanced system ensures continuous operation. The manual valve is used as a diaphragm, and the automatic valve maintains pressure and consumption in the risers. A manual balancing valve can shut off the system. The design is a valve type device. Manual valves can be installed in conjunction with shut-off valves.

Using valves with thermal heads

These are the best taps that can be installed on radiators in the heating system of a private home. Tuned to a certain air temperature, the thermal head acts on the valve stem, forcing it to open or close its flow area. In this way, automatic quantitative regulation of the coolant passing through the heating device occurs.

The thermostatic valve is installed on the supply line to the battery, and a balancing valve is installed on the return line. It is a mistake to assume that the system will be automatically balanced by thermal heads; valves are needed in any case. Installation of conventional ball valves instead of them is allowed for centralized heating or in systems with associated coolant movement (Tichelman loop). But it is unacceptable to regulate the coolant flow using a ball valve, and it will not work.

Advice. Most models of thermal valves have a mechanical blocking mode for the flow area. If you received products without such a mode, then to service the battery you will have to install an additional cut-off device, as shown in the diagram:

Flow regulator

Having installed energy metering devices, the question naturally arises of how you can regulate and control the supply of coolant, limit or add its flow. For this purpose, there are all kinds of automatic regulators, the use of which allows you to save money; they operate from outside air temperature sensors and return pipeline sensors. Another advantage of temperature controllers is that they control the temperature directly at the radiator installation site, unlike other devices. This advantage gives priority in obtaining a uniform temperature background for a comfortable stay in the room. The regulator will prevent overheating of the air in the room, which sensors on centralized automation cannot always track. It is possible to adjust the temperature for each room separately. Sometimes, when solving the adjustment issue, ordinary taps are installed. Of course, this solution reduces financial costs, but deprives a number of useful advantages. The faucet has limited functionality to open and close. There is a danger of stopping or airing the riser. By adjusting the heating using taps it is impossible to achieve the required temperature. Using automatic regulators, you can adjust the system accurately and efficiently.

The valve on the radiator is on the return line, you need

Well, as I understand it, there will be no heating in the whole house until you return the radiator or close the system. Again, as far as I understand, frequent flushing of radiators (systems) is not advisable, but I don’t care.

Frequent flushing is beneficial to the system, but only if you then fill it with prepared water. And yes, until you fix it, you won’t turn it on.

If the system is on water, the water is the same year after year, it is better than fresh because

1 it is degassed - there are few gases dissolved in it, which can create air pockets. 2 it is already neutral in relation to the system - it has dissolved what could be dissolved, where it was possible to deposit a precipitate - it has already deposited.

And if instead of water there is antifreeze, then God himself ordered to save it. It is more expensive than taps.

Of course, if installed, the taps are full bore.

It's better to put it in, of course. It’s not a fact that you will rarely use it, because... Now in a crisis, radiators can be molded from such a thing. draining the system in a couple of minutes?! Yes, you can go to the sewer, if there is one. Is it necessary to overfill the septic tank or have a capacity of 300 or more liters?

If the system is on water, the water is the same year after year, it is better than fresh because

1 it is degassed - there are few gases dissolved in it, which can create air pockets. 2 it is already neutral in relation to the system - it has dissolved what could be dissolved, where it was possible to deposit a precipitate - it has already deposited.

And if instead of water there is antifreeze, then God himself ordered to save it. It is more expensive than taps.

Of course, if installed, the taps are full bore.

I decided to install a return valve. Somewhere I came across an article on adjusting two-pipe systems if there are several radiators in the CO branch using a valve on the return line. I can't find this article right now. But as I remember, the point is that as you move away from the manifold, the valves are clamped less and less tightly. I'm right? I can find ball valves without any problems - will they fit? Or do you need a non-ball one?