The effectiveness and reliability of a fire suppression system is equally dependent on the quality and technical characteristics of each component, including the external and internal piping network. The material of pipes for internal fire water supply systems in modern systems can be very diverse, and the choice of a specific option is made at the design stage, taking into account the specifics of the facility and the operating features of the system:

- traditional hot-formed and electric-welded steel pipes have proven themselves well, but require additional protection from corrosive factors;

- galvanized pipes are in demand in gas fire extinguishing systems, as well as in systems that include sprinklers and deluge sprinklers;

- Fire-fighting water supply pipes made of a special type of polypropylene (for example, fusiolen FS) are becoming increasingly common in the construction of stationary fire extinguishing systems.

Polymer materials (polyethylene, PVC, polypropylene) are also included in metal and fiberglass pipes, which today are used in conventional water installations and in fire extinguishing systems with finely sprayed water. Stainless steel pipes, for all their excellent qualities, are too expensive and are almost never used in the process of creating an AUPT.

In general, the choice of materials and characteristics of fire extinguishing system pipes is regulated by the provisions of clause 11.20 of SP 31.13330.2012, which are carried out on a voluntary basis.

Classification of internal fire-fighting water supply

The internal fire water supply system is:

- water filled (under pressure)

- air (usually for rooms with negative temperatures)

- dry pipe (usually for multi-storey buildings)

The launch of the ERW system can be either manual or automatic.

Fire cabinets for the internal fire water supply system can be located on the following systems of the designed facility:

- on the drinking water supply system

- on the process water supply system

- on an automatic fire extinguishing system

- on the system of integrated drinking water and process water supply

- as a separate fire water supply system.

According to MGSN 4.19-2005, in high-rise buildings, the water supply systems of the ERW, AUP, utility and drinking and process water supply systems must be separate.

Checking the functionality of the ERW

The methodology for examining internal fire-fighting water supply systems includes the use of measuring instruments and testing:

- monthly:

- pumps are checked.

- once a quarter:

- visual inspection;

- once every 6 months (spring and autumn) testing and testing:

- water supply (spout). A water release report is drawn up;

taps and locking mechanisms;

- pressure;

- water jet parameters;

- cabinets with equipment;

- annually:

- testing hoses for stability, rolling.

The results are recorded in reports, statements, protocols, and performance certificates. Read more about the frequency and methodology for checking ERW here.

Download: Form of ERW inspection report.doc Download: Sample of filling out ERW inspection report.doc

Routing of internal fire water pipes

Internal fire piping for buildings up to 5 floors (inclusive), as a rule, is carried out with bottom wiring. For buildings with more than 6 floors (inclusive) - top wiring.

If the total number of fire hydrants in a building is more than 12, then it is necessary to organize a ringing of the internal backbone network with two inputs.

If the internal fire-fighting water supply system is combined with a drinking or industrial water supply system, a water metering unit with a bypass line is installed at the inlet. An electric valve (or solenoid valve) is installed on the bypass line, which is disconnected from the fire signal.

Note: Water spent on fire fighting is not paid for in the Russian Federation. Therefore, there is no need to pass it through a water metering unit.

Repair shut-off devices are installed on ring and looped pipelines in such a way that during repairs no more than five fire hydrants (FH) in single-story buildings and no more than three risers in multi-story buildings can be excluded from operation.

For bottom wiring, if there are more than 5 fire hydrants on the distribution pipeline (riser or drop), then shut-off devices must be installed at the bottom or top, respectively. If there are 7 or more fire hydrant risers (drops), then it is necessary to install intermediate shut-off devices.

Kinds

The complex of fire extinguishing systems is divided into two types according to its functionality and principle of use:

- General purpose water supply with fire protection function. In fact, this is an ordinary plumbing system that is used to consume water for the needs of production and consumption of water for people (drinking, washing, etc.). It is connected to the fire safety pipe system. Note that in this case, the water supply for extinguishing fires can be general (scattered throughout the entire facility) or local (for a specific area or building).

- Separate internal fire water supply. This is a scheme with risers to the height of the entire building, intended only for fire safety measures.

Any of the above circuits can be a dead-end, otherwise end, or ring. The first option is used in small buildings, where a maximum of 12 fire hydrants will solve the problem of extinguishing the fire. The ring scheme is also universal, ideal for all types of objects. This is a looped water supply system into which fire extinguishing agent can be supplied from either side. Therefore, the failure of one of the sections does not affect the efficiency of the others; it is simply cut off by shut-off valves.

Water consumption, number of jets, pressure, fire extinguishing time

The number of fire nozzles and the minimum water consumption for internal fire extinguishing is determined according to table 1, 2 SP 10.13130.2009 depending on the type of building, number of floors, fire hazard category of the building, degree of fire resistance, and construction volume of the building.

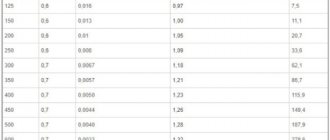

The water consumption for fire extinguishing from a fire hydrant is determined according to Table 3 SP10.13130.2009 and depends on the height of the compact part of the jet, the diameter of the fire hydrant, and the injection diameter.

According to clause 4.1.10 of SP 10.13130.2009, the operating time of fire hydrants should be 3 hours. When installing fire hydrants on automatic fire extinguishing systems, their operating time should be taken equal to the operating time of the automatic fire extinguishing systems.

According to clause 4.1.7 of SP 10.13130.2009, the hydrostatic pressure in the fire-fighting water supply system at the level of the lowest located sanitary fixture should not exceed 0.45 MPa.

The hydrostatic pressure in the separate fire-fighting water supply system at the level of the lowest located PC should not exceed 0.9 MPa.

When the design pressure in the fire-fighting water supply network exceeds 0.45 MPa, it is necessary to provide for the installation of a separate fire-fighting water supply network.

When the pressure at fire hydrants is more than 0.4 MPa, diaphragms should be installed between the PC and the connecting head to reduce excess pressure. It is allowed to install diaphragms with the same hole diameter on 3-4 floors of a building.

The main advantages of composite pipes:

- High corrosion and electrochemical resistance (service life 50 years or more);

- 3-4 times lighter than steel, with higher strength;

- High heat resistance, allowing to transport liquids with temperatures up to 1350 C;

- Low (an order of magnitude lower than steel) thermal conductivity (heat loss reduction by 30-50%, fuel savings up to 20%)

- Resistance to overloads, vacuum and other emergency situations

- No accumulation of deposits due to a perfectly smooth inner surface;

- Low hydraulic resistance (25-30% lower than steel);

- The internal, specially selected lining layer of the pipes provides resistance to almost any aggressive environment, abrasive, and also, due to its high elasticity, provides a high degree of tightness against impacts, bends, etc.;

- High degree of tightness and reliability of joints (more than 10 types of joints have been developed for specific operating conditions);

- High speed and ease of installation,

- Working pressure from vacuum to 250 Atm., diameters from 20 to 4000 mm.

The economic effect of using turnkey composite pipes (taking into account logistics, installation and service life) reaches 3-5 times compared to steel pipes and thermoplastic pipes.

As you can see, HELYX fiberglass pipes have a fairly wide range of applications and have a number of significant advantages. On our website you can fill out a questionnaire and order pipes and connecting parts for specific operating conditions.

HELYXPIPES divisions are ready to produce pipes and fittings from composite materials with high quality and on time according to your drawings and technical specifications

Pumping stations and reservoirs in internal fire water supply systems

If the pressure in the external network is not sufficient for ERW (i.e., the guaranteed pressure at the input to the ERW system is less than the required pressure in the ERW system), then it is necessary to install a fire extinguishing booster pumping station.

Note: If the fire water supply in the building is combined with technical or domestic drinking water supply, then it is necessary to design two groups of pumps:

- utility and drinking (technological) pumps to ensure the required water flow and pressure for drinking and drinking (technological) needs. These pumps are usually equipped with a frequency converter.

- Fire-fighting pumps to provide drinking water (technological) and fire-fighting needs of the designed facility (flow and pressure in case of fire). These pumps must have the appropriate certificate. And they do not have a frequency converter. Fire pumps are started from the “Fire” signal. After they are started, the pumping unit for utility and drinking (technological) purposes is automatically switched off.

If the pressure in the external network is less than 0.05 MPa or the water from the external water supply is not enough to meet the needs of internal fire extinguishing, then it is necessary to design fire-fighting tanks in which the necessary fire-fighting water supply will be stored.

Polypropylene pipes when organizing ERW

Basically, ERW piping is made from steel pipes. But in some areas where it is difficult to carry out installation work, polypropylene pipes are used, with only one caveat - they must have a fire safety certificate.

Polypropylene pipes have their own serious advantages:

- they are resistant to condensation;

- they have high wear resistance;

- complete absence of rust, which reduces the internal diameter of steel pipes;

- ease of installation;

- low specific gravity, which reduces the load on the entire pipe structure;

- polypropylene does not burn;

- no leaks at joints due to the absence of welding points;

- installation, repair and replacement can be carried out in any premises, because it does not involve hot work, that is, it is possible not to stop the technological process.

Fire cabinets, valves, hoses

The fire cabinet must comply with GOST R 51844-2009.

The requirements for a fire damper are set out in GOST R 53278-2009.

Requirements for fire hoses are given in GOST R 51049-2008.

Fire hydrants are located on staircases, corridors and other places along escape routes.

It is impossible to install a fire hydrant in smoke-free stairwells, as was regulated in MGSN 4.19-2005, because in this case, when laying a fire hose outside this stairwell, it will prevent the closing of the door isolating the smoke-free staircase from other rooms of the building. But if the door is not closed, then the smoke-free stairwell loses its functional purpose.

According to clause 4.1.13 SP 10.13130.2009, fire hydrants should be installed in such a way that the outlet on which it is located is at a height of 1.35 m (+/- 0.15 m) above the floor of the room. Paired PCs can be installed one above the other, with the second tap installed at a height of at least 1 m from the floor.

— Drawing of a fire cabinet.

What to remember

By tradition, we summarize, dear reader, our study of fire extinguishing pipelines.

- The fire water supply pipe is made of galvanized steel, brass, bronze, and copper. In some cases, the use of plastic pipes is allowed.

- The fire pipe is always painted red.

- When designing a fire extinguishing water supply system, be guided by GOST 14202-69, SP 5.13130.2009, SP 30.13330.2016, SP 8.13130.2009, GOST 8220-85, GOST 32569-2013 and other standards.

- The pipe may use welding to connect sections or have a seamless technology.

- For gas fire extinguishing, only galvanized steel pipes are used.

- The dry pipe is always installed from the end or rear side of the structure.

With that, dear readers, I would like to wish you all the best.

Subscribe to my blog and recommend it to your friends.

See you in the next article!

Indoor and primary fire extinguishing device

According to SP 54.13330.2016, clause 7.4.5, on the drinking water supply network in each apartment, a separate tap with a diameter of at least 15 mm should be provided for connecting a hose equipped with a sprayer for use as the primary fire extinguishing device in the apartment to eliminate the source of fire. The length of the hose should ensure that water can be supplied to any point in the apartment.

Currently, the domestic industry produces several types of UVP:

- indoor fire extinguishing devices “Rosa”, “Rosa-M” and “UPV”;

- household fire hydrant PK-B;

- KPK-Pulse indoor fire extinguishing devices.

Fire extinguishing pipelines

Any automatic fire extinguishing installation requires the presence of piping to deliver fire extinguishing agents to the source of the fire.

Without this, we will not be able to start putting out the fire.

But let's start, as always, with a definition.

According to the international standard GOST 32569-2013,

pipelines are a structure made of individual pipes, metal and other components,

securely connected to each other, designed for transporting liquid and gaseous materials.

In some cases, bulk materials are also delivered through pipelines.

But in firefighting we deal mainly with gas, water, foam or aerosol.

"FIREPROFF Flow"™

Services

To make a request

Find out the cost of products. Create a specification. Calculate the project for free.

Calculator

Hydraulic calculation of pipelines AUPT, TRV, ERV. Program for an engineer.

Quality control

Conducting incoming and acceptance inspections of Fireproff products.

Comparison of metal and plastic

Feasibility study of the use of materials for AUPT. Accurate calculation!

Laboratory

Testing of pipes for all fire safety indicators.

About production

High-tech production of pipes for water fire extinguishing.

Ecology

Environmental policy of the enterprise.

| Home |Products |Objects |Certificates |Dealers | © 2012-2020 "Fireproff". Use of site materials without a backlink is prohibited FREE CALLS IN RUSSIA 8 |

What is an external fire water supply

The purpose of the external fire-fighting water supply is to transport the extinguishing agent to the place where the fire is extinguished. The laying of the water pipeline takes into account the placement of points on it for water intake by fire equipment - hydrants (HG), taps (PK).

Basic concepts of NIP:

| Characteristic | Description |

| Concept | A set of measures and means to provide water through the external pipeline of fire-fighting devices in protected areas, special vehicles, and firefighting equipment. |

| How it works, what it consists of | Tasks:

Elements:

|

| Accommodation | Outside buildings, most often laid underground |

In what cases is it permissible not to provide NIP?

It is allowed not to provide water supply for external fire extinguishing in settlements and for objects:

- up to 50 people for buildings up to 2 floors;

- Separate fire hazard structures located outside the boundaries of populated areas:

- F3.1 – up to 150 m²;

F3.2 – up to 1 thousand m²;

- F1.2 – F4 and with I – IV type of fire resistance up to 250 m²;

- F5 with resistance levels I and II cat. D for explosion hazard up to 1 thousand m²;

- F5.2 – up to 50 m²;

- seasonal acceptance and procurement facilities for agricultural products up to 1 thousand m³.

NIP designation sign

The designation of the main element is used - “Fire hydrant” (number F09 according to GOST 12.4.026-2015) - a square (from 250x250 to 500x500 mm) white with a red rim (blue-white signs are outdated) with the following designations:

- required:

- "PG" (red);

arrows with distance in meters;

- recommended:

- device number;

type of external network: “T” – dead-end, “K” – ring;

- pipe diameter icon (crossed out circle) and value in mm (200, 250, etc.).

The second NIP sign is “Fire water source” (F04) - a red square with a white designation of a fire engine hose lowered into the water with an arrow to the water intake point and distance meters.

Main menu

Hello! Internal fire water supply is the name given to a set of pipelines and technical means (pumping stations that increase the pressure in the network, control units, water tanks) that ensure timely supply of water to the internal fire hydrants of buildings. Internal fire water supply (IFP) is intended for prompt, timely extinguishing of fires, fires at the initial stage of development in the premises of buildings by employees of enterprises, personnel of institutions, organizations, members of voluntary fire brigades (VFD). This allows you to quickly extinguish the fire and prevent further development of the fire before the arrival of the Ministry of Emergency Situations.

It is often used by fire department guards during reconnaissance of the location of a fire during fire extinguishing. The presence of ERW in buildings, its proper maintenance and use makes it possible to save people’s lives and preserve material values.

You can find red boxes with sleeves and trunks in many administrative institutions, medical, trade, educational institutions, manufacturing, as well as in high-rise residential buildings. The mandatory presence of ERW at certain facilities is dictated by state regulations and codes of practice (SP) in the field of fire safety.

Device requirements

Currently, several official documents are in force - the Federal Law “On Fire Safety” (No. 69-FZ dated December 21, 1994, as amended on January 10, 2016), as well as SP, national standards (GOST), regulating all issues regarding the design of ERW, terms, test methods, markings, maintenance of system elements in working condition:

• SP 10.13130.2009 “Fire protection systems. Internal fire water supply. Fire safety requirements" (as amended by the Ministry of Emergency Situations of Russia dated December 9, 2010). This is the main document that determines the need for the device and the technical characteristics of the ERW.

• SP 118.13330.2012* “Public buildings and structures. Updated version of SNiP 06/31/2009.”

• SP 54. 13330.2011 “Residential multi-apartment buildings. Updated version of SNiP 31-01-2003.”

• GOST R 51049-2008 “Fire fighting equipment. Firefighting pressure hoses. General technical requirements. Test methods".

• GOST R 53279-2009 “Fire fighting equipment. Fire connecting heads. General technical requirements. Test methods".

• GOST R 51844-2009 “Fire fighting equipment. Fire cabinets. General technical requirements. Test methods".

• GOST R 12.4.026-2001 SSBT. “Signal colors, safety signs and signal markings. Purpose and rules of use. General technical requirements and characteristics. Test methods".

• “Fire regulations in the Russian Federation”, approved by Resolution No. 390 of the Government of the Russian Federation dated 04/25/2012 (as amended on 04/06/2016).

In addition, there are industry standards, departmental rules for organizing ERW, which take into account the specifics of enterprises, the physical and chemical properties of substances, materials, equipment involved in the technological process of production, finished products. As an example, we can cite the ban on extinguishing substances that react with it by releasing heat with water, as well as the fact that extinguishing burning flammable and combustible liquids is carried out with mechanical foam, but not with water, to prevent the spread of the fire area. Accordingly, the installation of ERW in such industries is impractical.

Where needed

According to table. 1 SP 10.13130.2009 for public, residential buildings, administrative and amenity blocks of industrial enterprises, it is necessary to install an ERW with the number of fire trunks, the minimum water consumption for fire extinguishing, depending on the purpose, number of floors, construction volume:

• Residential buildings with a height of 12 to 16 floors. Requires 1 barrel with a minimum flow rate of 2.5 l/s.

• The same, with a corridor length of over 10 m - 2 barrels of 2.5 l/s per stream.

• Residential buildings 16–25 floors. Requires 2 barrels of 2.5 l/s.

• The same, with a corridor length of more than 10 m – 3 x 2.5 l/s.

• Office buildings from 6 to 10 floors, with a volume of up to 25 thousand cubic meters. m. – 1 trunk x 2.5 l/s.

• The same, with a volume of more than 25 thousand cubic meters. m. or a height of over 10 floors, a volume of less than 25 thousand cubic meters. m. – 2 x 2.5 l/s.

• The same, with a height of over 10 floors, a volume of more than 25 thousand cubic meters. m. – 3 x 2.5 l/s.

• Cinemas, theaters, clubs with a stage, assembly and conference halls with a stage, equipped with film equipment - in accordance with the requirements of SP 118.13330.2012* “Public buildings and structures”.

• Dormitories and public buildings (except for administrative buildings) up to 10 floors inclusive, with a volume of 5–25 thousand cubic meters. m. – 1 trunk x 2.5 l/s.

• The same, with a volume of more than 25 thousand cubic meters. m., as well as a height of over 10 floors, a volume of less than 25 thousand cubic meters. m. – 2 x 2.5 l/s.

• The same, with a height of over 10 floors, a volume of more than 25 thousand cubic meters. m. – 3 x 2.5 l/s.

• Administrative buildings of industrial enterprises with a volume of 5–25 thousand cubic meters. m. – 1 trunk x 2.5 l/s.

• The same, with a volume of more than 25 thousand cubic meters. m. – 2 x 2.5 l/s.

For industrial and warehouse buildings up to 50 m high, the need for an ERW device is determined according to Table. 2 SP 10.13130.2009 depending on the degree of fire resistance, fire hazard category of buildings, construction volume:

• I, II degree of fire resistance, category A, B, C, volume from 0.5 to 5 thousand cubic meters. m. inclusive - 2 x 2.5 l/s.

• The same, with a volume of over 5 to 200 thousand cubic meters. m. inclusive - 2 x 5 l/s.

• The same, with a volume of over 200 to 400 thousand cubic meters. m. inclusive - 3 x 5 l/s.

• The same, with a volume of over 400 to 800 thousand cubic meters. m. inclusive - 4 x 5 l/s.

• III degree of fire resistance, category B, volume from 0.5 to 5 thousand cubic meters. m. inclusive - 2 x 2.5 l/s.

• The same, with a volume of over 5 to 200 thousand cubic meters. m. inclusive - 2 x 5 l/s.

• III degree of fire resistance, category G, D, volume from 5 to 200 thousand cubic meters. m. inclusive - 2 x 2.5 l/s.

• IV, V degree of fire resistance, category B, volume from 0.5 to 5 thousand cubic meters. m. inclusive - 2 x 2.5 l/s.

• The same, with a volume of over 5 to 50 thousand cubic meters. m. inclusive - 2 x 5 l/s.

• IV, V degree of fire resistance, category G, D, volume over 5 to 50 thousand cubic meters. m. inclusive - 2 x 2.5 l/s.

These requirements apply to designed and reconstructed ERW systems of buildings.

In addition, in accordance with clause 7.4.5 of SP 54. 13330.2011 “Residential multi-apartment buildings”, each apartment should be provided with a separate tap with a diameter of at least 15 mm for connecting a hose equipped with a sprayer for use as the primary device for internal fire extinguishing to eliminate the source fire. The length of the hose should ensure that water can be supplied to any point in the apartment.

Water consumption for fire extinguishing

It depends on the height of the compact jet and the spray diameter of the fire nozzle tip. Water consumption should be determined according to the table. 3 SP 10.13130.2009, which provides the standard parameters of a fire hydrant (FH):

• Valves DN 50 and DN 65, where the numbers indicate the nominal diameter in mm.

• Fire hose length – 10, 15, 20 m.

• The spray diameter of the fire nozzle tip is 13, 16, 19 mm.

• The height of the compact part of the jet is from 6 to 20 m.

To obtain a jet with a flow rate of up to 4 l/s, a firebox is designed with a DN 50 valve, and to obtain greater fire nozzle performance - with DN 65 components.

Design of ERW

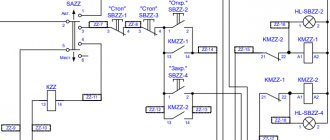

At the first stage, the PC is placed on the floor plans of the building, ensuring the supply of the required number of jets to any point in the premises. Then a hydraulic calculation of the system is performed in fire extinguishing mode, and the estimated water flow rates in all areas are determined. The final design of the circuit, selection of pipe diameters, pump power, shut-off, instrumentation, and starting valves are being carried out.

ERW composition, requirements

The internal fire water supply system of buildings consists of the following elements:

• Shut-off, control and measuring valves at the inlet. The fire-fighting water supply system, as a rule, is combined with a drinking water supply or industrial water supply system with sufficient pressure in the network under conditions of the maximum possible flow rate.

• Fire pump (station with control unit) ERW. Provided for insufficient pressure in the external water supply network. Placed on the 1st or basement floor of protected buildings in water distribution, heating points, boiler rooms, boiler rooms, and separately designated premises.

• Water pressure, hydropneumatic tanks. They contain an emergency fire-fighting water supply for the initial stage of extinguishing before starting the pumps. If the automatic switching on of fire pumps is guaranteed, the reserve may not be provided.

• Vertical risers, horizontal ERV networks. They are designed and laid taking into account the optimal placement of PCs in the building. In buildings with a height of 6 floors or more, fire risers with a combined system of utility and fire water supply are looped at the top. Made from welded steel pipes. It is permissible to use polymer pipes that have a fire safety certificate in integrated water supply systems. The autonomous ERW of the building must be made of steel pipes.

• Buttons for manual start of the fire pump (station) near each PC or blocking of the ERV electric valve with the building's automatic fire alarm system to ensure timely rise of water in the system. Both starting options are also used to increase starting reliability.

• Internal PCs. Installed at entrances, in lobbies, halls, on landings of staircases, corridors, passages, and other most accessible places based on the possibility of irrigating each point of the premises with 1 or more jets, depending on the requirements of SP 10.13130.2009 for the building. The PC is installed at a height of 1.35 m from the floor. It is allowed to install paired taps - side by side or one above the other on the same riser.

• Manual fire nozzle with connecting head, fire hose with 2 connected heads. Placed in locked boxes, adapted for visual inspection without opening or sealing near the PC.

The building's ERW system must be in working, complete condition, ensuring readiness for use to extinguish a fire at any time. During the period of repair work, it is necessary to take additional fire safety measures and strengthen the fire safety regime.

Usage

When a fire occurs, the first priority is to evacuate people from the building. At the same time, some of the enterprise’s employees, institution, and organization personnel begin to extinguish the fire using a manual fire nozzle from the fire station closest to the fire site. As a rule, extinguishing is carried out by members of the voluntary fire brigade (VFD), for which it is necessary:

• Training in the necessary techniques and skills of working with a manual fire nozzle.

• Availability of personal protective equipment against dangerous fire factors.

• Studying, passing tests on site instructions on fire safety, on actions in case of a fire, taking into account the features and specifics of buildings.

Creating a DPD at a facility is the prerogative of the head of an enterprise, organization, or building owner. From the statistics of the Ministry of Emergency Situations: unprepared people, no matter how much they want, cannot quickly and correctly lay a fire hose with a barrel to the location of the fire, supply water, or work effectively with the barrel.

Content requirements, checks, responsibility

The “Fire Regulations in the Russian Federation” (issued in 2012 to replace PPB-01-93) require strict compliance with the following requirements related to the content of ERW:

• From paragraph 23 “e”. It is prohibited to make changes to space-planning solutions and placement of utilities and equipment, as a result of which access to fire hydrants is limited. Typical examples: installing a partition to highlight a new office, an office that isolates a PC in the room, or a warehouse of unnecessary furniture near it.

• From clause 55. The head of the organization ensures the serviceability of the ERW and organizes performance checks at least 2 times a year (spring and autumn) with the preparation of relevant reports.

• From clause 57. The head of the organization ensures that the ERW PC is equipped with fire hoses, manual fire nozzles and valves, and organizes the rolling of fire hoses (at least once a year). The fire hose must be connected to the PC and the fire nozzle, placed in wall-mounted, built-in or attached cabinets made of non-combustible materials, having elements to ensure their sealing and fixation in the closed position. The fire cabinet must allow doors to open at least 90 degrees.

• From clause 59. The head of the organization ensures the good condition and performance checks of electric valves (at least 2 times a year), fire pumping units (monthly), with the date of checking the technical condition of the equipment recorded in the log.

Routine work on the maintenance of ERW can be carried out both by employees of the relevant technical services of the enterprise, the owner of the building, and by third-party organizations providing services in the field of fire safety, on the basis of contractual obligations.

In accordance with the Federal Law “On Fire Safety”, heads of organizations are obliged to: comply with fire safety requirements, as well as comply with orders, regulations and other legal requirements of fire officials. Employees of the federal fire supervision of the Ministry of Emergency Situations of the Russian Federation, during inspections of the fire safety condition of buildings, are required to evaluate the staffing and performance of the ERV. In case of gross violations, the manager, persons responsible for fire safety, and operation of ERW may be held administratively liable.

Water supply sources for external fire extinguishing system

The fire external water supply system takes extinguishing resources from artificial and natural sources:

- natural objects:

- seas;

rivers;

- lakes;

- ponds;

- fire storage facilities - underground metal and concrete containers buried to a depth below the freezing point;

- reservoirs – tanks, structures inside and outside premises;

- other water supply systems: technical, drinking.

When a reservoir becomes polluted, a well with filters is built into which water flows by gravity.

Requirements for fireproof external water supply system:

- total minimum volume of water and number of storages: 2 pcs. for 1 water supply unit, 50% of the norm in each;

- the supply should ensure extinguishing for 3 hours;

- water intake structures, piers for fire engines (minimum 12x12), receiving wells, and coarse filters are installed near the sources;

- must have frost protection.

Connection price

| Pipeline diameter, mm | price per m. | price for shut-off and control component |

| 15 | from 90 rub. | from 450 rub. |

| 20 | from 90 rub. | from 585 rub. |

| 25 | from 90 rub. | from 585 rub. |

| 32 | from 135 rub. | from 675 rub. |

| 40 | from 135 rub. | from 675 rub. |

| 50 | from 225 rub. | from 900 rub. |

| 65 | from 270 rub. | from 2250 rub. |

| 80 | from 315 rub. | from 2700 rub. |

| 100 | from 360 rub. | from 4050 rub. |

| 125 | from 450 rub. | from 5850 rub. |

| 150 | from 495 rub. | from 6750 rub. |

| 200 | from 630 rub. | from 7650 rub. |

| 250 | from 765 rub. | from 8550 rub. |

Fire water supply pipes

The effectiveness and reliability of a fire suppression system is equally dependent on the quality and technical characteristics of each component, including the external and internal piping network. The material of pipes for internal fire water supply systems in modern systems can be very diverse, and the choice of a specific option is made at the design stage, taking into account the specifics of the facility and the operating features of the system:

- traditional hot-formed and electric-welded steel pipes have proven themselves well, but require additional protection from corrosive factors;

- galvanized pipes are in demand in gas fire extinguishing systems, as well as in systems that include sprinklers and deluge sprinklers;

- Fire-fighting water supply pipes made of a special type of polypropylene (for example, fusiolen FS) are becoming increasingly common in the construction of stationary fire extinguishing systems.

Polymer materials (polyethylene, PVC, polypropylene) are also included in metal and fiberglass pipes, which today are used in conventional water installations and in fire extinguishing systems with finely sprayed water. Stainless steel pipes, for all their excellent qualities, are too expensive and are almost never used in the process of creating an AUPT.

In general, the choice of materials and characteristics of fire extinguishing system pipes is regulated by the provisions of clause 11.20 of SP 31.13330.2012, which are carried out on a voluntary basis.

Inspection and maintenance of NPV

The service life of underground hydrants for external fire-fighting supply is 10 years, trouble-free operation must be guaranteed for 200 opening/closing cycles.

Check (GOST 12.4.009-83, R 53961-2010, Guidelines for organizing control over NSPV):

- 2 times a year (spring and summer) – test (for water loss) and for performance;

- every 6 months – technical inspection (a certificate of serviceability is issued).

The results are displayed according to Form 21 (GOST 2.601, 12.3.006), and a performance certificate is drawn up. The responsible person must ensure free access, cleaning of the area, covers of water intake points, vertical arrangement of hydrants in wells, and unhindered opening.