Corrosion is a specific process in which solids break down over time. This can happen not only due to certain chemical reactions. Sometimes corrosion is the result of electrochemical processes. It often appears on the surface of a substance and indicates that its subsequent destruction has begun. Some chemical elements are capable of reacting with the environment, as a result of which corrosion can form on some surfaces, destroying even durable materials.

There is corrosion that occurs on various materials. However, the most common is metal corrosion. Due to this result of a chemical reaction, the economies of many countries suffer serious losses. The thing is that the most common type of corrosion is rust, which sometimes requires replacing the entire metal structure.

At the moment, pipes with anti-corrosion coating are becoming increasingly popular, making it possible to maintain the overall performance of the device of which they are part. Thanks to this development, most manufacturers of various goods breathed a sigh of relief. After all, now there is no need to dismantle and reinstall pipes that were damaged by metal corrosion after a few years.

About protecting metal from corrosion - why is this necessary?

As a rule, during pipe operation, corrosion inevitably appears upon contact with the external environment. Both the external and internal parts of the pipe are susceptible to it.

The reason for the destruction of the outer side is the interaction of soil and metal. The fact is that the soil contains dissolved salts, i.e. liquid electrolytes. They corrode the outer shell of the metal pipe.

Taking this provision into account, during the construction process a decision is made on what type of pipeline will be used and what protection it should have. There are two types of protection:

- active (electrochemical);

- passive (insulating).

It should be noted that pipes laid above ground must be coated with a layer of zinc or aluminum. Other weather-resistant materials may be used.

Important! Pipes that will be laid near the paths of electric vehicles will be subject to corrosion due to the action of stray currents.

Pipes with protective coating

Since at the moment oil and gas are becoming increasingly popular as universal types of fuel, it is worth thinking about how to provide high-quality transportation for them.

Therefore, it is important to create pipes at enterprises that would be protected with a special anti-corrosion coating that prevents the destruction of pipe walls or the occurrence of corrosion on their surface, which leads to their destruction.

Projects are being created that would be designed to improve energy security in a particular country. We can say that in our time the world is experiencing an industry boom in pipeline transport. Thus, a situation has been created that allows for the construction of pipeline systems that could become an alternative to the existing ones.

Russia is a rapidly developing country that is trying to invent and develop new and advanced types of protective coatings. Surprisingly, our specialists have already created pipes containing polyethylene insulation.

It is important to be aware of the fact that the installation of such pipes can only be carried out efficiently by a professional who understands such issues.

It is no secret that technologies that provide solutions to such problems were invented several decades ago. If the pipe has a 3-layer polymer insulation consisting of several layers, then the insulation of the pipe joints should be similar. The only type of this type of insulation will be heat-shrinkable cuffs.

Popular brands of anti-corrosion compounds

Today, there are many popular brands producing anti-corrosion compounds. Here are the most popular ones.

- “Nerzhamet” is a special anti-corrosion enamel that is applied not only to clean pipe surfaces, but also to surfaces already covered with rust.

- "Nerzhalux" - known for their high degree of adhesion. Applied to aluminum, titanium, brass, copper and other surfaces.

- “Tsikrol” is a specialized enamel that is used to treat galvanized steel pipes.

- “Phosphor soil” - used when processing pipes made of ferrous and non-ferrous metals.

Now you know about the types of anti-corrosion coatings for pipes. Tell us in the comments - do you have metal pipes and how do you protect them from rust?

Types of metal corrosion

There are two main types of corrosion, differing in the degree of damage that it can cause. A distinction is made between direct and indirect corrosion.

If corrosion has caused direct damage, in this case the metal coating cannot be restored. Therefore, you will have to change all equipment that consists of metal parts. If corrosion has already damaged the metal, it is best to provide anti-corrosion protection. It, in turn, costs a lot of money, but after treatment with special substances and chemical solutions, the renewed metal coating will no longer be subject to oxidation and destruction from corrosion.

For this reason it costs a lot of money. However, after treatment with special substances and chemical solutions, the renewed metal coating will no longer be subject to oxidation and destruction from corrosion.

If the damage was indirect, only some parts of the metal structure are replaced.

In this case, funds will be spent on:

- purchase of appropriate metal,

- reduction in equipment power if the metal structure consists of pipes and other similar equipment,

- improvement of products, the main element of which is a metal frame.

Corrosion protection is the main task of modern designers developing various metal parts. In order for a structure to last for several decades, it is necessary to create all the conditions to protect it from external factors and various atmospheric phenomena, and the ability to influence the structure of the metal.

Modern technologies make it possible to develop an anti-corrosion coating for steel pipes, which provides the metal structure with additional protection from chemical elements that often come into contact with its surface.

Advantages of the composition

The Urizol coating, unlike many other polymer mixtures that contain varying amounts of organic volatile solvents, is a composition that includes one hundred percent solid phase. Polyurea does not contain plasticizers, which tend to “bleed” over time. This process is accompanied by gradual shrinkage and increased fragility of the protective film. The mixture does not include tar and coal components, which are often added to reduce the cost of the material, but have a carcinogenic effect on the human body. In addition, the composition does not contain solid fillers that provoke abrasive wear of pumping equipment, nozzles in spray installations and mixing chambers. Due to their high reactivity, polyurea components have a high level of polymerization without catalysts. The increased reliability of the coating is also due to its relatively low sensitivity to temperature and humidity changes. For example, other polyurethane mixtures of similar action have a higher tendency to form a porous film under the influence of moisture, which, in turn, is always present in the initial components of the raw material. It should, however, be noted that the reliability of polyurea is ensured only with careful compliance with the requirements for the preparation process of the structures and elements being processed.

Pipes and pipeline parts with internal anti-corrosion epoxy coating

This standard applies to steel pipes and shaped products with thermal insulation made of polyurethane foam, intended for underground laying of heating networks (in a polyethylene shell - in a ductless way, with a steel protective shell - in passage channels and tunnels) and above-ground laying of heating networks (for pipes with steel protective coating) with the following design parameters of the coolant: operating pressure no more than 1.6 MPa and temperature no more than 140°C. By agreement with the design organization, the use of insulated pipes in a polyethylene sheath in non-passable channels is allowed. It is also possible to use insulated pipes for pipelines transporting other substances (oil, gas, etc.).

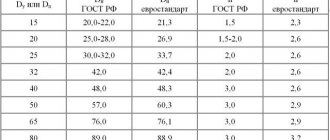

Product diameter from 32 to 1220 mm

Characteristics As a protective shell for thermal insulation of pipes, polyethylene shell pipes and shells made of thin-sheet galvanized steel with a rolled sealed seam (external and internal) are used. To increase the durability of a galvanized steel shell, it is allowed to apply an additional coating (paint, polymer, etc.) to its outer surface, which can be periodically renewed during operation. The outer diameter of steel pipes can be from 32 to 1220 mm. The length of steel pipes with a diameter of no more than 219 mm should be from 8 to 12 m, with a diameter of 273 mm and above - from 10 to 12 m. Pipes and fittings with a polyethylene sheath can be of two types: type 1 - standard, type 2 - reinforced. The length of the uninsulated ends of steel pipes with a shell diameter up to 355 mm inclusive is 150±20 mm, for pipes with a shell diameter of more than 400 mm - 210±20 mm. The length of polyethylene and spiral shells made of galvanized sheet steel must be equal to the length of the thermal insulation layer with a possible tolerance of +50 mm on each side of the product in accordance with the manufacturing technology. The thickness of the thermal insulation of shaped products must be equal to the thickness of the thermal insulation of pipes. The dimensions of shaped products (except for the diameters of steel pipes and shells) are recommended and determined by the project. It is allowed to manufacture shaped products, including fixed and sliding supports, according to the regulatory and technical documents of the design organization and the manufacturer, agreed upon in the prescribed manner. Thermally insulated pipes and parts must be equipped with conductors-indicators of the operational remote control system (ODC), however, it is possible to perform without them if there are design justifications or at the request of the Customer. The thickness of the thermal insulation layer, diameter and thickness of the shell given in the tables are for reference and can be specified by calculation depending on the specific design conditions and feasibility study.

Dyeing process

In fact, there can be only two options for painting radiator heating pipes - when the paint is applied to new pipes or when the composition must be applied to previously painted batteries and pipes to them.

Option 1

Often you have to deal with new steel pipes immediately after purchasing an apartment in a new building. Often such radiators are not even coated with a primer, but simply cleaned. If there is rust on the surfaces of metal pipes, it must be cleaned mechanically. Otherwise, the paint on metal simply will not adhere properly.

In order to solve this problem with your own hands, you can use regular sandpaper. Also, do not forget about coating the pipes with a primer and degreasing compound.

Remains of slag on welds can be removed using a light hammer, after which the pipes should be wiped with white alcohol. If the pipe is made of copper, then the process of preparation for painting ends here. In the case of the steel version, rust must be removed.

Preparing for painting.

If the case is too advanced, then you can use a grinder to process the seams on the pipes. For steel pipes, a rust converter can be applied to the surface, which can easily convert the too loose layer of the pipe into a smooth film. Applying paint to the film is not difficult. But it is preferable to first treat this area with a primer.

It is very convenient to use alkyd primers, which often contain a rust converter. As a result, when applying the primer, you can immediately achieve the desired effect. Usually information about this is indicated directly on the packaging.

The final stage in this option is painting the surface of the pipes in two or three layers with the selected coloring composition.

Option 2

If you need to paint radiator pipes that have already been painted previously, it is advisable to completely remove the previous composition from their surface. This need can be explained by two factors:

- The first of them is an exclusively aesthetic nuance, because if you apply new paint on top of an old one that has deformed over time, you won’t be able to get a beautiful, even layer;

- The second is that it is difficult to repair or replace pipes if necessary, since the fasteners are literally welded over time under several layers of paint.

Removing old paint will not be difficult if you use a remover for this purpose that can soften the paint layer. Next, all that remains is to clean off the melted old paint with a spatula. It is preferable to use a universal type of wash, as shown in the photo, since in this case you will not have to think about the composition of the old paint.

The procedure for carrying out work on anti-corrosion protection of pipelines

When laying, reconstructing and repairing pipelines, work is carried out on anti-corrosion treatment of the surface of the pipes. At the same time, the quality of processing must guarantee trouble-free operation of the pipeline throughout the entire period of operation.

Types of work to ensure anti-corrosion protection

To prevent damage to pipes by corrosion, active and passive protection is used. The active method of protection is electrochemical. Passive protection is protection using special insulating coatings. Where pipes are laid above ground, weather-resistant materials are used.

Protective materials

Underground, above-ground and above-ground methods of laying pipelines have their own characteristics, therefore, different materials are used for each laying method. To protect the surface of pipes, paints and varnishes are used, which are applied in a thick layer using airless installations at high temperatures. The following materials are used:

- “Protegol” from the German company Goldschmidt TIB GmbH is a group of protective materials based on epoxy and polyurethane for pipes and individual elements.

- “Permacor” from the Swiss company Sika AG is a group of materials for the protection of above-ground and underground pipelines.

- “FRUCS-1OOOA” from the Japanese company Kawakami Paint is a material for protecting individual connecting parts and shut-off valves.

All mentioned materials reliably protect pipelines for 15-30 years. The protection period depends on the operating conditions.

To cover above-ground pipelines, thin-layer coatings (up to 300 microns) are used, which reliably protect against atmospheric influences for 10-30 years. Such protection is provided by materials from INTERNATIONAL PAINT (Sweden), HEMPEL (Denmark), JOTUN (Norway), STEEL PAINT (Germany), as well as the Russian Morozov Chemical Plant.

Procedure for carrying out work to protect pipelines from corrosion

Surface preparation

The surface of the pipes is cleaned using the abrasive blast cleaning method according to the international standard ISO 8501-1 to a cleaning degree of SA-2.5. This removes the old coating and all contaminants, and also creates a rough surface (50-110 microns) for better adhesion of the anti-corrosion material. After cleaning, the surface is dusted using an industrial vacuum cleaner or blowing with compressed air.

The quality of cleaning is monitored visually, as well as with measuring instruments:

- The degree of purification is controlled by comparison with photo standards according to ISO 8501-1.

- The result of dust removal is controlled with adhesive tape according to the requirements of ISO 8502-3.

- Roughness is measured with an electronic comparator or profilometer and compared with the standard ISO 8503-1.

Coating with anti-corrosion materials

- Two-component coatings, forming a thick layer 1-3 mm thick, are applied in airless installations for applying high-viscosity materials with additional heating and separate feeding.

- Thin-layer one- and two-component coatings are applied in installations for medium- and low-viscosity materials with continuous or separate feed.

- Paints and varnishes undergo additional control and preparation before application.

- Climatic parameters (temperature, air humidity, dew point and others) during work are monitored by Elcometer 319 multifunction devices.

- The quality of work and film thickness after coating is controlled by quality inspectors using visual inspection and special instruments.

What should the paint be like?

Do you know which open communications have the greatest length in our apartments? Of course, heating systems, and since heating pipes are a special type of surface, the painting composition must therefore meet certain requirements.

Captain Obvious informs: it is not recommended to use ordinary paint on batteries and supply pipes, since, most likely, it will not live up to expectations and will quickly become unusable.

So, what paint should you use to paint heating pipes? Among the requirements, the most important are the following:

- Lack of water permeability . It is important that the paint functions as an anti-corrosion coating. Even if heating pipes are located in a dry room, there is a risk of rust on black steel. Properly selected paint will avoid this;

- The aesthetic point is no less important , since the color of the paint should not only not disturb the external aesthetics of the room, but also complement it. In principle, if the pipes are located in niches that will be closed in the future, then only protective properties will be required from the paint.

However, you should not hide any communication pipes with any insulating materials, as this will make it difficult to access them in the event of a breakdown;

Pipeline paint can be any color.

- Since the surface of the battery is often subject to heat, one of the most important points among the paint requirements is its resistance to high temperatures . Otherwise, the coating may become yellow in the future, and cracks and delaminations may appear on the painted surface.

- It is preferable to choose paints with good adhesion to metal , otherwise you will have to treat the surface to be painted with a primer.

How to get rid of corrosion

In order for a metal structure to last longer, it is necessary to treat the coating with special substances to prevent the formation of corrosion on the surface of the material.

The most common are pipes with an internal anti-corrosion coating, because thanks to the protective layer, they last longer. Special chemicals, which will subsequently protect metal pipes, are applied to their inside. Moreover, if corrosion provokes rust on the outer surface of the pipe, preventing its spread will be more difficult. In this case, manufacturers try to worry about the safety of the entire surface of the pipe in advance.

Therefore, the cost of such equipment, consisting of several metal parts, will be significantly higher. Manufacturers indicate on the accompanying instructions for the product that special protective substances are applied to the metal.

If there is no such protection, the pipe can last for several years until external factors acting on its surface lead to partial or complete destruction of the metal.

In this case, it does not matter where the pipe is located indoors or outdoors. Even if it is part of communications and is located in sea water, its surface is exposed to various chemicals.

The following are especially in need of corrosion protection:

- various types of pipelines located not only in the open air, but also in water,

- equipment, the main part of which is metal,

- metal frames of various residential premises and industrial buildings,

- all kinds of tanks,

- construction cranes,

- bridges,

- heat exchangers.

There are also pipes with an external anti-corrosion coating, created specifically for subsequent installation in enterprises and industrial workshops, where most of the basic chemical reactions and processes that speed up the production of goods often occur.

External protection of pipes from corrosion is as important as internal protection. However, if the manufacturer does not have additional financial resources to purchase the appropriate equipment, you can save significant financial resources by purchasing this type of pipe. Russia is currently investing heavily in the development and subsequent production of special substances that protect pipes from rust and other signs of corrosion on their surface.

Some regions of Russia have a humid climate. This is an ideal place for not only rust to appear on the walls of metal coatings, but also as a result of corrosion, which completely destroys metal coatings of any thickness and shape. If we take into account all the above factors, at the moment corrosion is the main problem that does not allow our country to develop fully. When our specialists are able to establish the production of special substances designed for anti-corrosion protection of metal surfaces, the state will save significant financial resources, which are spent annually on the purchase of such chemical compounds abroad.

In addition, there is no need to replace pipes and other metal coatings over time, the service life of which expires due to rust and corrosion that destroys their surface.

The use of anti-corrosion protection products can significantly reduce material losses in most developed countries of the world.

At the same time, Russia needs to take its place among producers of such goods. This will allow our country to take a leading position not only in the production of necessary goods and chemical elements that prevent the destruction of metal surfaces. In this way, it will be possible to conclude a sense of mutually beneficial contracts that will allow Russia to cooperate with other states.

There are several ways to apply an anti-corrosion protective coating to a metal surface. The most common is the barrier method of processing metal surfaces. That is, the substance is applied directly to the coating surface itself. Even if it contains additional chemicals, the anti-corrosion protection will fulfill all the functional characteristics and properties assigned to it. For example, if a metal surface is painted with some kind of paint and varnish material or contains impurities of other substances and materials such as nylon, the substance will not enter into various chemical reactions with them, but will retain a strong structure.

Just as paint and varnish materials create a protective film on the surface of the material, anti-corrosion substances form an additional coating, which in turn is not washed off with water. Over time, even such anti-corrosion substances lose their properties. Therefore, over time it is necessary to repeat the processing procedure.

However, before choosing certain means to protect a metal surface, it is also necessary to take into account the characteristics of the metal itself. Even the conditions under which the process of applying a substance to metal occurs plays an important role for its further operation and performance.

Therefore, Russian manufacturers are seriously thinking about creating an effective, inexpensive product for protecting metal surfaces from damage and all sorts of consequences of corrosion.

Technologists have already achieved certain results by developing several universal compositions that interact with most metals. But they still need to be refined and further improved. Subsequently, these compositions and substances will provide complete protection to pipes and other metal structures.