So, the topic of our article today is again the well. Moreover, it was prepared as a continuation of the topic we started a little earlier. And it is addressed, in principle, to those who are planning to acquire their own source of water supply. In today's part, we will tell you, first of all, about what casing pipes are used in the construction of wells. We will also touch upon issues related to the selection of a team to carry out the work, the selection and installation of a pump, and piping the trunk of the water supply source being created.

You can read the first part of this material by clicking on this link.

Well and casing: popular sizes and technical characteristics

A well can be drilled, in principle, using various technologies. Therefore, the moment of installation of the casing pipe may vary. Installers can lower it into the shaft either during the drilling process, or after completing excavation work.

In fact, the body of the well is the casing pipe, usually made of metal or plastic. But let’s clarify right away: it’s best to buy only metal ones. Because with them the well is more reliable and durable. The pipes used consist of separate sections. And they are joined to each other using a threaded connection.

Plastic products are less suitable for use in the wellbore. Due to their light weight, installation is much easier. However, the strength of the walls is too weak to withstand the pressure and other influences of the surrounding soil. It is perhaps worth emphasizing that agreeing with the contractor and purchasing plastic casing pipes means acting at a loss.

In principle, there is a direct relationship between the diameter of the casing pipes and the cost of drilling a well. But of the several options offered to choose from, it’s not worth buying the smallest one. It may happen that it will not be possible to lift water through such a thin pipe. Because there are no pumps on sale with such a connecting diameter. Something average in size will cost more. But in the end, the consumer will win. Moreover, the larger the diameter, the greater the water consumption the well can provide.

Which casing pipe to choose

As a rule, customers are offered casing pipes of two diameters - 127 or 133 mm. It is best to choose the larger one. The advantages of such a solution are probably clear:

- the water supply will be sufficient so that the dynamic level does not drop to critical values;

- there is no need to buy only a specific category of pumps, because 3” and 4” models are suitable.

For pipes with a diameter of 127 mm, only 3” pumping equipment with a connecting diameter of 76 mm is suitable. Models of this group are less numerous on sale. Their technical characteristics are noticeably inferior to 4” pumps.

A domestic well most often requires the purchase of 2-3 pipes. It is important to consider the following:

- sections of smaller diameter are installed in large pipes;

- catalogs usually indicate the outer diameter of casing pipes;

- the walls are quite thick, the exact value should be clarified.

Rules for installing the surface version

It is not practical to install surface pumps on deep hydraulic structures. When diving below 8 m, such devices fail. In small wells, their installation is justified due to their lower price than submersible options.

The installation procedure consists of the following sequential steps:

- A separate room is prepared to house the equipment. You can allocate space in the caisson for a surface pump.

- A rubber sleeve is placed on the suction pipe. Its length should be sufficient to connect to the aquifer.

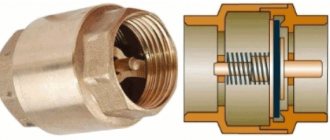

- A check valve is fixed on the opposite side of the hose. It performs the function of stopping the drainage of liquid when the mechanism is turned off.

- A strainer is mounted on top of the valve device. It sifts out silt fragments and sand granules.

- The end of the elastic sleeve is lowered into the water.

The process ends with a trial run.

Contracting team: rules for successfully choosing a contractor

It is perhaps impossible to give instructions in advance on how to successfully select a contractor. Moreover, there are a huge number of various offers on the market. It is very important not to end up associated with amateurs or incompetent people. The demand for drilling is huge, and therefore there are many who want to make quick money.

You can identify a truly serious company, so as not to get involved with a dummy, by a number of signs:

- there is an office where you can usually come or just call;

- the company has its own fleet of vehicles and equipment and does not borrow tools from third parties;

- the staff includes, in particular, hydrogeologists with higher education;

- services are provided to clients only on a contractual basis;

- before signing the contract, the consultant explains how the drilling will be carried out: technology, features, timing, etc.;

- the company is a member of the SRO (can present the appropriate permit);

- As a result, a technical passport will be issued for the well;

- the proposed options do not include plastic pipes with a diameter of less than 127 mm;

- if necessary, the well will be drilled to a depth of more than 50 m (that is, equipment of the appropriate capacity is available).

It is important to note that upon completion of drilling, the team is usually required to pump a new well. They do this until clear water comes out of the pipe. It is best for the customer to oversee this work personally. After this, control measurements and test pumpings are performed. The results are entered into the technical passport and the warranty is filled out.

Drilling

Forming a well on the site is impossible without special equipment. In private households, a shock-rope device is more often used, which looks simple but works effectively. The working mechanism is a supporting tripod with a driving device. The tripod structure requires metal pipes that are connected to each other by welding. A device called a “glass” is connected by a winch to a cable. The height of the support is firmly linked to the length of the driving unit. Metal pipes connected to each other should be 1.5–2 m higher than the “glass”.

- Next, do-it-yourself drilling occurs using a winch.

- Drive the “glass” into the designated work area in a private yard. With its help, soil is removed from the site.

To determine the depth of the well, it is important to consider the following

- The level of occurrence of an aquifer in a specific area.

- Household needs and domestic water needs.

When choosing a casing, it is worth considering that it must withstand heavy loads. In addition to mechanical strength, the pipe must not be prone to corrosion. The material must withstand pressure. Asbestos cement pipes are the most famous and frequently used for wells. The catch with using such products is that if the well silts up, it can no longer be restored. Currently, manufacturers offer casing products from the following materials:

- steel;

- plastic;

- tree.

Steel products are expensive and leave a characteristic metallic aftertaste in the water. Plastic pipes appeared on the market not so long ago, but they already surpass their competitors in many characteristics. The taste of the water does not spoil; it is cheap compared to asbestos-cement options.

Wooden pipes for wells are little known even to specialists, as they are rarely used today. Variants of these pipes are not very durable.

Having selected and installed the casing pipe for the drilled well, you can proceed to the installation of equipment.

Well and pump: suitable pump modifications for well service

The reliability and efficiency of a well is largely, perhaps, determined by the correct selection of a pump. Such equipment operates, in principle, in difficult conditions throughout the year. Therefore, negligence in the selection of especially critical equipment results in losses for the owner.

Pumping stations and surface-type pumps are not suitable for operating domestic wells. That is, specialized models are required that differ in design complexity. The most important characteristics include, in particular:

- high resistance to sand;

- presence of an engine cooling system;

- hygienic design;

- long service life.

A model with a long service life usually has a well-known, trusted manufacturer who is ready to provide a guarantee. When purchasing a pump, all its characteristics are taken into account together, having written out the parameters of the well in advance. Some of them can be taken from the technical data sheet, but some will have to be measured with your own hands or calculated. In particular, these are:

- well productivity (flow rate);

At what dynamic level are pumps installed?

The equipment is lowered into the well based on its total depth and dynamic level height. The body of the device should be as high as possible, but without the risk of diving to the surface. When it is necessary to perform a deep dive, it is important not to exceed the depth allowed according to the data sheet of a given model.

As a rule, automation allows you to prevent the most common risks. An important addition to any model of well pump is a check valve. Some models already have a built-in one, but experts insist on installing an external one. The reason is simple: if the valve is built-in, then if a blockage occurs, there will be no choice but to remove the pump and send it for repair. If the valve is external, then it is easy to remove and clean it yourself. Its diameter is selected, in principle, equal to the adapter (connector) or the lumen of the pump outlet pipe.

On the section of the route from the pump to the entrance to the house, it is best to use HDPE plastic pipes. It is not only reliable, but also cheap. But when purchasing, it is important to make sure that the pipe is food grade and not technical. The technical specifications must indicate the marking - SDR 11. Such pipes comply with GOST 18599-2001 and can withstand pressures of up to 16 atmospheres.

To suspend the pump in the well, use a stainless steel cable and clamps (clamps). To avoid chafing of the cable at the attachment point, it is allowed to use thimbles. Particular care is taken to ensure that the weight of the pump is distributed along the cable. For safety reasons, it is prohibited to hang it on a pipe or cable.

Film on water in a well ↑

The film on the water is the result of contamination with petroleum products. Oil products enter the well in three ways (the first and second are clearly preferable to the third):

- oil leaked from a depressurized pump - one of the elements (dry running protection, for example) of some models is filled with oil, when the pump fails for one reason or another, oil can get into the water;

- accident - Annushka poured oil (and not vegetable oil) in the wrong place;

- pollution of the aquifer with petroleum products - runoff from gas stations, industrial wastewater containing petroleum products mixed with flood, storm or melt water and penetrated into the formation through infiltration.

If the water in the well smells of kerosene, you need to understand that there is nowhere for it to come from, and most likely the aquifer is polluted.

Film on water in a well

Sorbents are used to clean a well from oil products. The use of detergents is strictly prohibited (this will simply replace one pollutant with another). The water from the well must be pumped out, the walls of the shaft must be washed, and the bottom must be cleared of sediment consisting of the remains of a large fraction of petroleum product and sorbent. Please note that when mixed with water, petroleum products form light, medium and heavy fractions, which makes it difficult to visually assess the effectiveness of cleaning: the film on the surface will disappear, but the contamination will remain. A chemical analysis of the water is required.

These measures will help get rid of accidental contamination, including that caused by a pump malfunction. If the aquifer is contaminated, a one-time cleaning will not help - you will need a water purification system or the source will have to be closed (analysis will show the degree of contamination) and an alternative will be found. It takes a very long time for aquifers to be cleaned naturally.

If an oil film is detected on the surface of the water, you must (without delay):

- establish the cause of contamination;

- if the problem is in the pump, replace the equipment;

- limit water consumption to the maximum, without reducing the water level in the well until cleaning activities are carried out;

- clean the well;

- pump the well several times and flush the entire water treatment/water supply system.

To clean a well from oil products, we recommend contacting specialists - it’s inexpensive, but much more effective than trying it on your own.

Domestic well and rules for mounting a pump in its trunk

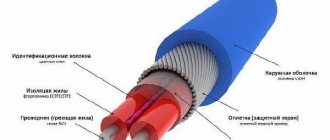

As a rule, a protective centering guide is installed every linear meter of casing pipes. Such a simple but effective element prevents abrasion of the electrical cable and damage to the pipe by the metal cable. Moreover, with the correct positioning of the cable, there is no critical cable tension. These elements do not rub against each other and always remain strictly in the center of the well.

The cable is attached from above to the well head. The pump's electrical cable will have to be connected to an extension cord. Because most of the models on sale have a standard cord about 1.5 m long. When buying an extension cord, take into account that not every model will fit. It is best to consult with the pump seller regarding the selection of a suitable cross-section (a popular cross-sectional area is usually 2.5 mm2). The power cable itself will only work if it is specifically designed for use in water.

You can connect the power cable to the power cord using a heat shrink kit. Filled couplings are also suitable for this purpose because they are considered more reliable. If the connection point does not go too deep, you can use IP68 detachable couplings. These are also convenient for fixing connection points along the entire power supply path to the house. The advantage of IP68 couplings is especially in their waterproofness, heat resistance and suitability for outdoor use. If the system has to be repaired or dismantled, a detachable connection turns out to be much more practical than a permanent one.

When for some reason there are no centering guides in the internal cavity of the casing pipes, you will have to press the electric cable to the water main. For this purpose, as a rule, plastic clamps are purchased. They are used along the entire length of the power cable, fixed at intervals of 100 cm. It is important to ensure that no sagging occurs anywhere along the entire length. The installation on the way from the well to the house is carried out in a HDPE pipe of a smaller diameter than was purchased for water.

Casing diameter

For the Moscow region, where the depth of aquiferous limestone ranges from 80 to 140 meters, the optimal option for casing a well is considered to be a steel column with a diameter of 159 mm with a plastic production pipe of 125 mm (internal diameter 111 mm).

The advantages of such a system: the ability to install a standard 4-inch pump, and most importantly, maintainability. When the pipe reaches the end of its service life, there is no need to drill the well again. It will be enough to install a pipe of smaller diameter inside the old “waste” pipe.

In other words, a wide diameter potentially doubles the life of the well!

Well and its trunk piping

The strapping parameters are selected in advance, taking into account the climate of the area and operating conditions. The main difficulty is usually the need to protect equipment and water pipes from freezing in winter. But this is not a problem if you follow the rule: the water main must be laid below the freezing point of the soil. In the Moscow region, for example, the recommended minimum depth is 1.5 m.

Caisson pipe exit method

Caissons are hermetically sealed containers that are dug into the ground below the freezing point (known for the area). They are built around wells and made of sufficient volume so that any necessary work can be carried out without hindrance: installation, repair, service, etc.

For the construction of a caisson, metal and concrete are probably suitable. Welded metal and monolithic concrete are considered more durable and reliable than plastic ones. But their cost is much higher. The water pipe exits the caisson below the freezing point. To ensure ease of operation, lighting is installed inside the tank, a ladder is installed, and pump controls are installed.

Moreover, great attention is paid to ensuring dryness inside. To do this, a cap is mounted on top to prevent not only precipitation, but also debris and dust from getting inside. The pump cable is also attached to the head.

Connection Features

Installation of pipes involves a strong and reliable connection of all parts.

There are three main connection methods:

- by welding;

- bells;

- threads or fittings.

If we are talking about asbestos-cement pipes, then in this case only couplings are used.

Installation also requires compliance with certain requirements:

- the edge of the pipe should not reach the bottom by about 50 centimeters - this will ensure the free passage of water at any time;

- the diameter should not decrease when deepening, as this will lead to loss of water permeability;

- each link should be attached as firmly as possible, depending on the characteristics of the material - for example, at least four staples and strips of stainless steel.

Well and effective measures to protect it

Every time the pump is lowered or raised, impacts on the adapter are inevitable. It is important to provide special protection against them. Because each blow inevitably leads to an increase in play between the parts of detachable connections. Because of this, leaks are possible. You can protect against this by using a starting torque compensator.

To protect against the entry of foreign objects and dust into the well, a cover is usually installed on top. Moreover, a terminal box is additionally integrated into it. In this way, the power supply to the pump is turned off before dismantling it. Moreover, a detachable coupling performs a similar function.

It is often impossible to install a water pipe into a house at a depth below the freezing point of the soil. If this happens, then the critical section of the main line is covered with a heating cable. For those owners who visit the house only from time to time in winter, it is useful to take care of comprehensive protection against freezing of the water supply. To do this, water is drained from the pipes. This is not difficult if the pipeline is laid at the required slope. As a rule, a drain valve is installed at its lowest point.

In all other cases, you will have to purge the pipeline with a compressor. A more convenient way to solve this problem is to install an automatic or manual drain valve. Then the water from the main will flow back into the well when drained.

After completing the piping, you can start using the well. Moreover, the basis for simplifying the operation process is the installation of automation equipment. We’ll talk about them in more detail in the final part of our article.

The end of this material can be found at this link.

If dismantling is necessary

If you are interested in the question of how to remove the casing from a well, then it is extremely important to understand why you should bother with this process at all.

There are at least two reasons:

- restore an abandoned source;

- repair the existing one.

You have decided that replacing the casing pipe in a well is necessary, then in this case this process can be performed in several basic ways.