We all have moments when we want to do nothing and just sit and enjoy our free time. A garden swing made from a profile pipe, which you can make yourself, is suitable for this. You can calmly sit on it, lie down or take a nap. There are two- and four-seater options. Some models are equipped with a canopy that can protect from rain or sun, and comfortable seats guarantee comfort.

Design and design of a rocking chair made of a profile pipe with a polycarbonate canopy

Peculiarities

If there are children in the family, having a swing is an excellent option for spending free time. There are a huge number of garden swings on sale. But assembling a structure with your own hands is always interesting and exciting. There are several types of metal garden swings that you can make with your own hands:

- for the whole family (a massive structure consisting of a large bench that can accommodate young and old);

- for children (small swings that consist of one or two seats, only a child can ride on them).

How to equip a swing on a tree?

The simplest type of garden swing is its installation on a tree branch. If there is a sufficiently mature tree in the garden at the dacha, the branch of which can be used to attach a rope, the issue of their arrangement is solved simply:

The classic version using a plank and a pair of nylon ropes for fastening

For these purposes, we pay attention to fastening the cables, using the safest knot. We drill holes in the board and pass a cable through them, which is attached to a tree branch. It is better to use oak for these purposes, if you have one.

If not, you need to take action: inspect the branch on which they will be attached; it should not have cracks or be diseased.

If chains are used for reliability, they must be wrapped in a plastic tube so that your fingers do not get caught in the chain links.

It is necessary to check the condition of the branch on which the gurney is attached weekly for safety. When kids want to ride them, check them out yourself first.

dd84985189385bccd404a41087ba3f90.jpe

Choosing a place to install a swing on the site

For portable and stationary models, it is recommended to choose a flat area. If the supports are not level, the wobbly supporting frame will bend or tip over. One side of the foundation will have to be buried too deep, which will lead to waste of material. If it is not possible to find a dry area, the ground is covered with crushed stone or tiles are laid.

It is best to place a hanging sofa for relaxation in a quiet place where there are no annoying noises. It is better to place a children's swing under the windows near the house - if the child falls, you will need to act urgently. The playground must be visible. It must be torn away from the roadway and fenced off from it. Don't set up your play space next to your garage or workshop.

The supports are mounted at a safe distance from the wall to prevent the possibility of impact. It is important to position the structure so that your gaze does not rest on an obstacle: a wall or a fence.

Racks should not be installed under pipes or power lines. If the wire breaks, they will be excited.

made of canvas on chains

Here, too, everything is simple - there is a chain + there is a metal triangle + there is a piece of thick tarpaulin.

We hang the iron triangles on a chain - we pass a piece of tarpaulin through the triangles - we bend its edge to the bottom and put 2 large rivets. Ready.

If there are no rivets, you can simply thread the bolts through and tighten them with nuts - and to prevent the bolt from breaking through the hole, then lay wide metal spacers on both edges. And with your own hands you quickly and easily made a soft garden swing from fabric.

MODEL FOUR – garden swing made from chairs.

There are three different ways to attach our rope to such a “chair-like” seat.

Method one (blue chair from the photo above) – under the seat of the chair, we place 2 thick metal rods (one under the seat of the chair from the back, the other from the front under the seat). We cut round holes in the corners of the chair - thread ropes into them - and tie the ends of the steel rods with these threaded ropes. Thus, we get a rigid structure of our swing

Method two (yellow swing from the photo above) - we nail 2 boards to the bottom of the chair - we drill holes in them - we thread ropes into the holes and secure them with a fastening knot.

Method three (pink swing-chair) – We knock together a small shield from planks. We drill holes in it. We put it under the seat of the chair. We drill grooves in the seat of the chair (not holes - but grooves, that is, vertical cuts along the edge of the seat) 2 through grooves from the front corners of the seat + 2 grooves from the back side of the seat.

The ropes pass through the front grooves - go under the seat towards the shield - there they enter the front holes on the shield - come out of the back holes on the shield - and pass into the rear grooves of the chair seat - and go up to the support on which they hang.

This grooved design is very durable - remember?.. we have already made such grooved fasteners for swings in the article “Swings for a summer house - 20 ways to make them yourself.”

Children under 6 years old

Children are lightweight, which allows you to create a swing that is simple in design. At the same time, do not forget about the correct level of security, which should be as high as possible. For such a swing, a pipe with a diameter of more than 50 mm is suitable. Before you begin assembly, you should take care to draw up a detailed drawing.

In this case, an L-shaped structure with a height of 1.5 to 2 m is quite appropriate. It is optimal if the swing is implemented in a portable version, which is achieved by welding a square base.

Next, a metal rod is used, which is bent so that it takes the shape of a hook. The length of such a segment should be about 1 m, taking into account the fact that about 50 cm of the rod will be underground. To ensure acceptable stability, it is enough to fix the swing at four points.

How to fix the seat

To install the seat, you will need to provide the ability to attach a suspension, which can be done as follows:

- use clamps of the appropriate profile, supplemented with a hook for the fastening element;

- make holes in the crossbar and install anchor bolts in them with a loop attached to the end;

- mount bearings, which are a reliable method of fixation, but require constant lubrication to avoid annoying squeaking.

The seat itself is suspended using a synthetic rope (climbing equipment), a chain or a metal cable (automotive). In this case, it is not recommended to use household appliances. If you choose the option with a chain, you must use a product made of galvanized steel. A simple design will rust, and painting it will be quite problematic.

The best material for a seat is wood. If you plan to install a large seat, then a metal frame is required.

Drawings and photos of DIY garden swings made of metal: dimensions and technology

DIY garden swings can have different types of frames. Based on this feature, the following design options are distinguished:

- collapsible;

- welded

Welded rotary types require the use of a welding machine and other special equipment. As a result, you will have a strong and rigid supporting part that will allow you to operate the structure for many years without any risk to health.

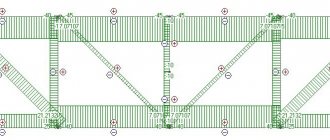

Installation dimensions of the garden swing frame in profile pipes

If you do not know how to handle a welding machine, choose a folding swing. The principle of assembling the frame is to twist all the elements of the product with bolts and nuts. Anyone can do this kind of work.

Note! Over time, in a handmade metal garden swing, the threads of the connections gradually weaken under the influence of weight and other loads. As a result, the game (free space) is displayed. It can cause structural failure, resulting in injury to a person. To prevent this from happening, secure the elements with grooves and locknuts. Do not forget to regularly tighten the joints with a wrench.

Modern design metal garden swing

Brief classification of DIY metal garden swings

The easiest way is to make a structure using ready-made drawings of a garden swing with your own hands from metal. Looking at the diagrams, it can be noted that the configuration of the supports is different.

The base of the A-frame consists of two beams connected at the top. The jumper is located approximately in the middle of their growth. It is designed to increase structural rigidity. There are supports without a platband, L-shaped.

Children's light swing made of metal with support pillars in the shape of the letter A

Another type of support is elements with a crossbar, forming a U-shaped base. Creating such a structure requires less effort, but the swing is less stable. Their operation will be strong and safe if the foundation supports are placed in deep holes in the ground and well cemented.

In addition, all metal products can be divided into two groups:

- stationary – the load-bearing part of the swing is securely cemented;

- portable - fixed with anchor bolts or bent reinforcement driven into the ground.

A metal swing located in the garden of a private house will become a favorite place to relax

Technology for creating a swing with your own hands from a profile pipe

The most common design options are hanging swings. They are convenient, practical and convenient. Equip the product with a canopy to protect it from direct sunlight. Thanks to this, the seat does not overheat and the driving process will become even more comfortable.

To make a canopy for a children's swing from metal with your own hands, you can use textiles, tarpaulin, wood with soft tiles in the form of a roof. But the most suitable material is cellular polycarbonate. Polycarbonate sheets are transparent, so it will not be dark under the canopy. At the same time, they perfectly transmit direct sunlight.

Drawing of a garden swing frame from a profile pipe

List of necessary tools and materials

Before you make a garden swing with your own hands, make sure you have the appropriate tools:

- building level and tape measure;

- electric drill;

- a series of drills designed for working with metal and wooden surfaces;

- welding machine and protective devices (for working with the machine);

- Bulgarians;

Mobile hanging rocking chair with metal frame

- set of wrenches;

- self-tapping screws designed for fastening polycarbonate sheets.

- screwdriver;

For work you will also need to purchase materials, namely:

- metal profile (pipes and corner);

- wooden planks or blocks for assembling the seat;

Metal swing of an original shape, suspended from a tree branch on a rope

- washers and nuts for bolts (for fastening the seat);

- fasteners made of stainless or galvanized steel (carabiners, support hooks, eye bolts, chains);

- long anchors or bent reinforcing bars (for attaching the structure to the base);

- bolts with semi-countersunk heads (for fastening to the seat);

Device diagram and installation dimensions of the metal rotating frame

- protective agents for the frame (primer with anti-corrosion properties and paint and varnish composition for metal surfaces);

- protective means for the wood from which the seat will be created (stain, varnish, set of brushes for surface treatment).

- sheet of cellular polycarbonate (roof canopy);

The choice of designs when creating a metal swing with your own hands is wide and limited only by your imagination

Drawings and photos of a do-it-yourself metal swing: preparatory stage

At this stage, a platform for attaching the swing is selected, and the dimensions of the structure are determined. The optimal size of a hanging bench is 1.5 m. This is enough for two people to sit on a swing or lie down.

Helpful advice! Make sure you create a gap between the post frame and the bench wall. Minimum size 300 mm.

Dimensions for making metal children's swings

According to the drawings of a do-it-yourself garden swing made from a profile, the structure consists of the following elements:

- side walls consisting of a pair of tubes welded together;

- horizontal bar for hanging a bench.

- rectangular support frame at the base;

The process of creating a swinging garden structure from metal pipes

This information will help with further assembly. Thanks to this design, the structure acquires the required level of rigidity. By choosing the right base width you can create a very stable product. Take the rule as a basis for your work: the larger the angle at the apex of the triangle between the base and the side walls, the more stable the structure will be.

Diagram of a metal rotating frame with A-shaped struts: 1 – flange; 2 – nut; 3 – crossbar; 4 – ring nut; 5 – support frame; 6 – subframe; 7 – bolt

General dimensional parameters are calculated individually. Indicators related to the polycarbonate canopy and hanging bench are adapted to them. Experts recommend that it is mandatory to prepare drawings indicating all dimensional parameters of the structure to make it more convenient to work with the material. Subsequently, this will save you from mistakes and save time.

Size of different metal rocking chairs. You can make similar drawings with your own hands

Do-it-yourself assembly of a swing from a profile pipe according to drawings: frame part

It is recommended to start installing the frame from the side parts. To do this, based on the drawings, you need to mark the pipes and cut them with a grinder. Please check the dimensions for accuracy before installation. All four side wall elements should be similar to each other. They need to be connected in pairs by soldering. As a result, you should have two identical L-shaped parts.

Diagram of the frame structure with dimensions for a metal garden swing

Next, the sharp end located at the top of each part is sawed off at one level. This procedure is carried out in such a way that a small supporting platform is formed for fixing the horizontal bar.

Helpful advice! Use a pre-prepared template to work with.

A metal swing of an unusual shape can become the main attraction of a personal plot.

The width of the support frame (short side) must correspond to the distance that is formed between the connected pipes of the side parts of the structure. The welder welded the side walls to the rectangular support frame, then the horizontal cross member (above the side posts).

All stages of assembling the frame part must strictly obey the laws of geometry: the side posts have a vertical type arrangement, the horizontal crossbar (beam), intended for hanging the bench, runs parallel to the base. Use the building level to control build parameters.

Diagram of the frame of a children's swing made from a profile pipe

Wooden swing seat assembly technology

Assembling the bench is an important stage of construction. Especially if you make a metal children's swing with your own hands according to the drawings. At the base of the seat there should be a support frame consisting of a steel angle. To get a bench with a comfortable backrest, place it at a certain angle to the seat. The optimal angle is 120°.

Family type garden swing with metal frame and wooden seat

To get the correct angular bend, cut a triangle (60°) into the shelf. The seat frame is a rectangular metal profile made by welding. The side parts must be connected along the edge sections using horizontal jumpers. The connection point should also be where the structure folds.

Three different versions of the rocking seat with a metal base to which wooden slats are attached

Helpful advice! If desired, the design can be improved by adding armrests to the seat. They will improve comfort and safety.

Regardless of whether you are making a children's swing with your own hands or a product for adults, the back and seat must be absolutely smooth. For these purposes, wooden blocks or boards carefully processed with sandpaper (first with coarse grain, then with fine grain) are suitable.

An unusual type of hanging swing with a metal frame

The boards are cut to the required size and attached to the frame through pre-drilled holes with bolts so that their heads are recessed. Before final assembly of the structure, wooden elements are treated with antiseptic and paint, and metal elements are treated with primer and paint.

Eye bolts are attached to the corners of the frame part of the bench. The chains will be attached to the ears of these bolts using carabiners or threaded connections. To hang the bench, you will also need to install eye bolts at the corners of the product or along the edges of the seat.

The procedure for making a garden swing with a metal frame

Making a canopy for the structure

The process of making a visor is optional. But if you are creating a swing for children with your own hands, you should think about comfort and protection from the scorching sun, as well as from rain.

To do this, you need to make a rectangular structure, which will be based on a metal frame, reinforced with jumpers. A sheet of cellular polycarbonate is fixed on top of the structure. The canopy is installed at a slight angle, so that precipitation will drain freely.

Metal swing such as a sofa with a canopy, installed in the courtyard of a private house

To complete the frame part of the visor, take several metal profiles of a small square section. All these elements are fixed by welding, after which the visor can be attached to the top of the rotating frame. This is also done using a welding machine.

When all installation work is completed, the structure is subject to final processing. The surface of the swing is coated with a primer and then painted in any desired color.

Various options for creating a polycarbonate canopy over a swing

The final stage of construction

When the paint is completely dry, a polycarbonate sheet is attached to the frame of the visor. To do this, use self-tapping screws with sealing washers.

Helpful advice! Cover the ends of the sheets with a polymer profile. It will protect the hollow polycarbonate structure from insects and dust, maintaining its beauty and cleanliness.

A wide range of colors is one of the advantages of polycarbonate. You can choose the color of the visor to match the color of the swing or, conversely, make it contrasting. In addition, the color of the material directly affects the level of sunlight dispersion.

A wooden pergola serves as a base for hanging a metal swing

The finished product must be securely fixed on a concrete platform. If the structure is being built on dense soil, several clamps made of reinforcing bars can be used to secure the frame. Firstly, the ends of the clamps must be sharp, which will allow you to drive the rods into the ground 0.5 m without any problems.

It is best to use anchor bolts as fasteners on a concrete platform. They are pre-installed in appropriate locations. After tightening the nuts, cut off the excess wire with a grinder. At this point, construction of the facility is completed.

Sofa swing for a summer residence

Country sofa swings are in great demand. If it is not possible to buy them, then they try to make them themselves. Metal options are highly durable. And if it is also properly processed, it will not be afraid of moisture.

Tools and materials for manufacturing

For production you will need metal profiles, a welding machine and seating material. Typically, wood is used for such purposes. In addition, you will also need material for the roof. Those who plan to use polycarbonate should know that it is quite hot under it in sunny weather, and it is not practical during hail (the material begins to crack). It is ideal to take a tension awning.

How to make a garden swing with your own hands from metal: instructions with photos

Let's start following the instructions for assembling the garden swing.

| Illustration | Description of action |

| We weld the frame. You can take your own sizes. It all depends on how much material you have. As a result, you should get a base like the one in the photo. | |

| We weld the frame for the swing to which the sofa will be attached. Next, we bend the arcs from the metal profile. They will play the role of armrests | |

| We hang the finished part on carabiners. Next we prepare the tree | |

| The finished version should look like this. The swing folds out into a sofa. The upper part of the frame is attached to the frame using strong chains. All metal parts must be primed and then painted |

To make the bed soft, it can be covered with a special fabric or periodically laid on top of a mattress and pillows for relaxation.

Dear readers, if you do not understand enough about the question of how to make a garden swing with your own hands, do not hesitate to ask questions and share your opinion. Our team will definitely contact you as soon as possible.

df229d53ba1e4c70efa4a4ca0e2d3f45.jpe 4e6b3aed843bfeb2b8188c66d060b0a7.jpe

Basic requirements

Before starting work, you need to familiarize yourself with a number of requirements, compliance with which will allow you to create a high-quality product. Since garden swings are considered quite dangerous, care must be taken to ensure that no curious situation overshadows everything else. All elements must be reliable. And during operation, it is impossible for there to be objects nearby that could become an obstacle to the maximum swing of the swing.

As a rule, children love to swing. But sometimes adults don’t mind relaxing after a hard day at work. When deciding how to perform a swing, it is imperative to provide for a large load capacity and maximum dynamic load. A strong swing frame is important for safety.

Depending on where the swing will be installed, you choose what to do with it. Most often they are used in the garden, outdoors. Therefore, building materials must have weather resistance characteristics. Then they will last a long time. We must not forget the appearance. To make a handmade garden swing look neat, you need to choose materials that are easy to care for.

After analyzing all the requirements and deciding on the parameters, you can choose the type of product. According to the installation method, they are distinguished:

- Mobile. If there is no exact place for their installation, then it is better to opt for a portable model for the garden. Then the swing can be moved to any convenient place.

- Stationary. When creating a swing with your own hands, the installation location is determined once, it remains unchanged for the entire period of operation.

According to the principle of the device, they are distinguished:

- Suspended. The seat is attached to the frame using hangers.

- Frame. They are characterized by a solid frame welded from pipes or obtained from wooden beams.

Among the building materials, the most popular are garden swings made by hand from metal, wood or a combination of both. All of the above projects meet the requirements in one way or another. However, if you put safety above all else, a swing with a fixed metal frame is the best option. Compared to other options, they have greater stability and load capacity.

Useful tips

Both the back and the seat should be made as smooth as possible - it does not matter whether the swing is used by an adult or a child. Therefore, the ideal choice would be bars or boards that have been sanded with emery. Initially, processing is carried out with large grains, then its caliber is reduced. Pre-prepared recesses are used to secure the cut boards. Bolts are screwed into them, trying to drown the heads.

Before assembly is completed, the entire tree is impregnated with antiseptic and varnish. Metal parts must be primed and painted. Eye bolts are placed at the corners of the frame. To attach chains to the ears of such bolts, either threaded couplings or mounting carabiners are used. Benches must also be suspended using eye bolts. DIYers have the choice of whether to mount them on corners or over edges.

It would be useful to add a visor to the swing. Effective protection from precipitation and sunlight is very important not only for children, but also for adults. The canopy is a rectangular steel frame reinforced with lintels. A polycarbonate sheet is mounted on top of the frame.

The cross-section of the profiles for the visor is usually small. They are welded together and fixed to the top of the swing frame, also using welding machines. You can install the polycarbonate sheet only after the paint has dried on the metal. It is fixed with self-tapping screws supplemented with sealing washers. It is recommended to cover the end of the visor with a polymer profile, which will not allow insects or dust particles to penetrate inside.

Pros and cons of products

First of all, let’s look at the positive aspects of homemade products:

- designs can be made unique, which will add harmony and comfort to your summer cottage,

- a handmade product costs much less than in a store.

- metal swings are durable,

However, there are also disadvantages:

- the metal frame is quite rigid, so you should be wary of possible injuries and bruises;

- To avoid corrosion, special treatment of the material is required.

One of the most reliable materials is a metal profile pipe.

It has the following advantages:

- high resistance to mechanical damage;

- the quality corresponds to the profile of the casting, while this material is much more affordable;

- not subject to corrosion after special treatment.

- long-term use;

These are the main advantages of a metal profile pipe, but there are no ideal materials, so there are also disadvantages:

- difficult to fold;

- it is mandatory to use paints and varnishes or galvanization; without this, ferrous metal is susceptible to rust and destruction.

Selection of profile pipe

To build swings welded from metal, corners, round pipes, and brands are used. But more often they choose profile pipes, since they, compared to other types of rolled metal, have the following advantages:

- convenient form for work;

- the walls form stiffening ribs, which increases strength;

- resistance to mechanical damage.

Among the disadvantages it should be noted:

- the complexity of bending, you can’t do without a special machine;

- the need for high-quality corrosion protection.

Profiles of various shapes are used to manufacture swing elements:

- Bent parts are made from oval pipes, such as seats, arches, armrests;

- square and rectangular profiles are used for the manufacture of elements with heavy loads - racks and spacers;

- auxiliary parts are made from flat pipes.

Variety of models by type of fastening

Garden swings differ not only in shape and size, but also in the type of fastening.

Stationary

Fixed swings are equipped with two wooden supports (or pipes with a cross-section of 150-200 mm), which are installed in the ground and concreted.

The advantage is that they can be placed anywhere. This design itself is durable, its service life is estimated at many tens of years. It can withstand significant loads.

A fixed swing can accommodate up to four people, often with a canopy or canopy for protection from the elements.

To install beams in the ground, two small holes 1.4 meters deep and 45 cm in diameter are dug, fine crushed stone is poured (40 cm layer), it is well crushed. One end of the beam is primed, wrapped with waterproofing, and placed in a hole. Then you should prepare the concrete:

- 4 pieces of sand;

- 1 part cement.

- 5 pieces of small crushed stone up to 20 mm;

The rods are placed in a hole, centered at a two-meter level, fixed and filled with concrete. You should wait 2-3 weeks before subjecting such a support to any stress.

This construction is best done in the fall; according to the technology, the concrete is “good” for another five months, that is, this process will stretch throughout the entire winter period.

Mobile, hanging

This product is self-contained and does not require additional suspension. In addition, this model can also be moved to any location. The configuration may vary. The swing, which is fixed with chains, is durable. You can hang a more massive structure on them (withstand loads of up to 300 kg).

Among the disadvantages are the following nuances:

- large links can cause injury: if you pick up the chains while swinging, your fingers may get caught between the links;

- Use is only possible in cold weather because the joints are heated by the sun.

Garden swings that are attached to a rope are very popular in use because the price of such material is low, and the design with such a stand is very simple.

Professionals:

- safe use;

- does not require special support in case of suspension;

- easy to repair.

- affordable price;

Flaws:

- in the near future;

- Do not hang heavy structures.

How to make it for the street?

If you are interested in how to make an outdoor swing for children, then first you should choose a location, material and design. After you have prepared the drawing, calculate the number of materials and tools needed. Below, for your consideration, several swing options will be offered for installation on the street, in the yard or in the country.

Tire swing

The simplest design is a car tire suspended on a rope. The frame is a tree. The suspension means can be a chain secured with a bolt and nut. The second variation of this swing is done as follows:

- place the old tire horizontally;

- cut 3-4 holes in the upper part, insert metal hooks into them and secure them with washers and nuts;

- Thread chains or twine into the loops of the hooks and hang them on a thick branch.

Wooden swing

The classic and simplest option is a swing made from a board on ropes. Four holes along the edges and twine threaded into them are enough. You can also use a wooden lattice, a cut log, or an old chair without legs as a seat.

From scrap materials

Even an unnecessary hoop can serve as the basis for the seat. It is braided with rope so that you can sit quietly in the middle. The hoop is additionally wrapped in foam rubber, batting or other similar material for softness, then covered with fabric. At four or more points of the hoop, fasteners in the form of metal rings are fixed, ropes or chains are passed through them - all that remains is to choose the tree to hang the finished structure.

Canvas swing

Take two large metal triangles, rivets and a piece of tarpaulin. Fold the fabric several times and sew around the perimeter. Then insert the triangles and secure with rivets. Next, secure it to a tree branch using ropes.

Wooden swing on supports

The following materials should be prepared:

- strong rope;

- bars;

- plywood and slats for the seat;

- galvanized bolts for fastenings.

Dig two holes 1 m deep to secure the support beams. Treat the bottom of the supports with bitumen to protect against rotting. Install them vertically in the pits, cover them with a 30-centimeter layer of a mixture of crushed stone and sand, then fill them with concrete. Attach a cross beam to the upper ends of the posts. Make a seat out of plywood and a picket fence, or in the form of a bench. Secure to the support structure with strong ropes.

Metal swing on supports

You can also make a metal swing yourself. To do this you will need metal pipes and beams, hooks, a metal cutter, and a welding machine. The manufacturing process includes the following steps:

- cut the pipes into pieces of the required length - make 7 pieces of 2 m each and another 2 of 1–1.5 m each, 4 of the 2-meter ones are for the supporting sidewalls, 1 for the crossbar, and the remaining ones for the base of the frame;

- weld the rectangular base of the structure;

- weld the support posts to the base, then weld the crossbar to the upper ends of the supports;

- dig 4 holes to a depth of 80–100 cm;

- install beams in the finished pits; they should look slightly above the surface of the ground along the edges of the pits;

- fill the pits with beams with concrete;

- weld the hooks to the cross pipe;

- now weld the finished structure to the metal beams;

- attach the seat to the hooks.

Pendulum swing

To make this simple swing you will need 1 wide long board 5–7 cm thick, a cut log up to 70–80 cm high, 4 U-shaped fasteners made of reinforcement, 2 seats. First of all, dig a hole about half a meter deep. Install a vertically cut log into it and fill it with concrete for reliability. Next, cut four (two on each edge) holes in the middle of the board, 1 cm wide and 2–3 cm long. They should be located from each other at a distance equal to the width of the fastener. Cut two more similar holes closer to the edges of the board, leaving space for seats.

Attach 2 seats to the edges of the board. In front of them, thread them through the prepared holes and secure one U-shaped fastener so that the child can hold onto them with his hands. Lay the board horizontally on the log. Place the bottom ends of the two fasteners into the cut holes. Drive the fasteners into the log so that a few centimeters remain above the surface of the board, and most of it is securely seated in the log. Rock the board. Each edge should be able to touch the ground. If you did everything correctly, the pendulum swing is ready.

Choosing a site for construction

Before installing a garden swing, you need to decide on the place where it will be placed. A few tips to remember:

- do not install iron swings near communications (power lines, water supply);

- If there is a road nearby, you need to install a fence.

- It is better to place the swing near the house;

It is important that groundwater does not come close to the surface and that the ground is not swampy. A swing on a small slide would be an ideal option.

Garden swing in the form of a bench

When drawing up drawings of such a design, it should be assumed that the width of the seat for a person should be at least 0.5 m. The height of the bench from the ground is selected so that it is convenient to push with your feet while swinging. It can swing sideways, therefore, in order to avoid a collision of the bench with the supports, the distance between them for the cable is selected at least 0.35 m, for chains - 0.25 m. The height of the supports from the ground is selected 1.7 - 2.5 m, depending on swing method: sitting or standing. A separate drawing is made for the bench indicating the dimensions and angle of the backrest.

The seat width for one person must be at least 0.5 m

Preparation of materials

To ensure that swings for several people are durable but not bulky, they are made from profile pipes. For assembly you will need:

- wooden blocks 30 × 30 mm for covering the bench, but 20 × 50 or 30 × 70 are also suitable;

- rope, chain or other suspension capable of supporting 250 - 300 kg;

- 6 eye bolts with engraved nuts and washers for hanging the seat;

- metal paint and wood block paint.

- rectangular pipes with a cross-section of 15 - 20 mm for the manufacture of lintels and a frame for a bench;

- profile with a wall width of 40-70 mm and a thickness of 1-2 mm (depending on the number of people) for racks and traverses;

To avoid a collision between the bench and the supports, the distance between them is chosen to be at least 0.35 m for ropes and 0.25 m for chains

Step-by-step instruction

Assembly of a swing with front posts is carried out as follows:

- For the racks, 4 pipes are cut 2.5 m long, for the crossbar between them - 2.1 m.

- The ends of the pipes are cut at an angle of 30⁰ and welded in pairs in the form of isosceles triangles.

- Moving 2 m from above, a horizontal jumper measuring 1038 m is welded.

- A crossbar is welded to the top of the posts at a distance of 2 m from each other. Its ends protrude 50 mm on both sides.

- For the bench, wooden blocks 1.5 m long are cut, sanded and painted.

- On the prepared bench frame with welded fasteners for hanging, they are secured with bolts with a pitch of 20-25 mm. The distance between the rods can be increased or decreased depending on their size.

- The finished seat is suspended from the crossbar using eye bolts in the holes drilled on it.

- In the cleared area, 4 holes are dug 0.45 - 0.5 m deep.

- For pouring, a concrete mixture of cement, sand and water is prepared in a ratio of 1: 2: 3.

- The bottom of the pits is covered with a 10 cm layer of sand, and supports are installed. The free space is filled with stones and filled with concrete.

- Vibrations are tested in action after 3-4 days, when the concrete has completely hardened.

- If no defects are found, the structure is painted.

Swing drawings

Currently, on the Internet you can find a large number of design drawings for metal swings.

You can make a metal swing portable or stationary.

For children's games, you can equip a special playground at your summer cottage.

Portable swing

When mounting and installing a portable swing, 4 reinforcement pins are used to secure the legs. The ends of the pins can be easily bent with a vice to ensure that the swing is stable and prevents it from tipping over.

When installing such a swing, the pins are driven into the ground, and if they need to be moved to another place, they are simply pulled out of the ground.

Garden swings are welded for safety, and gussets are welded at the joints. Gussets are metal triangles that are welded at the corners of the connection between the crossbar and the supports.

They ensure the rigidity and reliability of the swing design. Portable swings are also very convenient because they can be put away for the winter so that they do not rust from the snow.

Stationary swing

They are convenient to use on areas that have a large area.

According to safety rules, when operating a swing, there should be about two to three meters of space behind and in front of the structure.

22fc6df727a5bdcf5ec654080abc2ba2.jpe

Helpful advice! After you install the swing, you must paint it with any metal paint. This will make your swing more attractive and protect it from rust.

Design

Before you start designing, it is advisable to decide on the type of frame, which can be folding/prefabricated (using bolts and nuts) or welded. If we talk about the first type, the assembly principle is to make parts of the appropriate length and calculate the correct pipe diameter for the bolts and nuts.

The welded structure is stronger and more stable; welding equipment is required for its manufacture. If you do not want to make an original, but completely standard product, drawings are not needed; you can use a ready-made diagram on the Internet as a basis.

To draw a sketch of a swing, you will need to consider the following dimensions:

- the seat height should be about 60 cm;

- for a mobile structure, it is necessary to maintain a distance between the support posts along the edge of the seat from 16 to 42 cm, it all depends on the type of fastening (cable, chain).

- square seat 55 cm;

Step-by-step instructions on how to make it at home

You can make a hammock chair in different ways. Each individual option is unique in its own way. It could be:

- wicker product on a rigid frame;

- designs with a cover;

- textile hanging item.

Tools

To make a hammock chair you will need the following tools:

- knife and scissors;

- sewing machine;

- hacksaw;

- awl and needle;

- paint brush;

- Ruler and pencil;

- hammer;

- pliers;

- screwdriver.

How to weave hanging macrame step by step?

To make it you will need the following materials:

- two metal hoops of different diameters;

- 900 meters of cord;

- 12 meters of slings;

- 2 thick cords;

- 2 wooden rods;

- work gloves.

Attention: metal hoops must have a cross-section of 3.5 cm. Then they will provide the product with maximum strength and reliability

As for choosing a cord for braiding, it is better to use a cord with a thickness of 4 mm. The manufacturing process is as follows:

- The frame is being wound. Any pattern can be chosen: checkerboard, macrame, with a flat knot.

- Next is the weaving of the seat. To do this, a thread is attached to a smaller hoop and a pattern is made.

- After this, the structure is assembled. The hoops are fastened together with a strong cord.

- Next, weaving the back is done. Its pattern should match the pattern of the seat. It is necessary to weave the back from above, gradually descending to the lower hoop.

- At the end of the weaving, there will be free edges of the threads from which the fringe is formed.

- The remaining ropes are used to weave strong cords for hanging the product.

Tip: It is recommended to work with gloves to prevent the formation of calluses and wounds on your hands when weaving.

The result should be a functional, durable and attractive chair that can be hung in your home, garden or terrace.

To hang the product in the garden, you need to hang it from a wooden beam using a durable carabiner. If the product is to be used indoors, a hole is made in the ceiling and filled with a special chemical made from polymers.

Next, a hook is mounted to the ceiling, onto which a chain for the hammock is attached.

Hoop swing

If you don’t know how to work with the macrame technique, you can make a hammock chair from fabric. This is a simpler and more convenient option. To do this you will need to use:

- gymnastic hoop with a diameter of 90 cm;

- durable fabric (about 3 meters) of any shade;

- padding polyester;

- 4 buckles and a ring for hanging;

- 3 meters of braid;

- 9 meters of tape;

- centimeter, thread.

The manufacturing process will look like this:

- We prepare a thick piece of fabric and cut out two circles, each 1.5 meters in diameter.

- According to a pre-made drawing, we mark holes for the slings at an angle of 45 degrees and cut them.

- Let's straighten out the circles. We sew a zipper into one of the circles in the middle of the product and leave it open.

- Sew two circles together with right sides together, leaving a margin of 1 cm from the edge.

- Turn the cover inside out and iron it.

- Using padding polyester, we wrap the hoop and tightly wrap the fabric on top, securing it with threads. This will make the frame of the product softer and easier to use.

- The hoop is placed in a sewn cover through an open zipper, after which we close the zipper.

To hang such a product in the garden or house, we prepare 9 meters of belt tape. We divide them into 4 equal parts and thread them into the cells that we left for the slings. We wrap the hoop with ribbon, fasten it and sew it with strong threads.

Advice: to prevent the belts from unraveling during operation, it is recommended to melt them with fire.

To make the product easily adjustable in height and tilt, we thread metal buckles into the free ends of the tape. The slings are assembled into a special iron ring and attached with a carabiner to the crossbar or ceiling.

Master class on fabric cocoon

Beginners are advised to start making a hammock chair with a simple and frameless design. The manufacturing process is as follows:

- We take a rectangular piece of fabric measuring 1.5 by 1.2 meters.

- We make slits on the sides of the cut every 8 cm. They should be rectangular with a width of 5 cm.

- Each cutout is covered with braid to prevent the fabric from unraveling.

- There should be 12-14 darts in total. They are all wrapped tightly and secured with strong rope.

- We close the free ends on both sides into one knot and make a loop.

The product is hung on two durable carabiners or on a wooden plank in the garden or in the house.

Tip: for outdoor use, you can also make an Adirondack garden chair, a folding chair, or unusual options from tires and pallets. And next to it you can put a folding picnic table or a convenient table for a laptop.

Preparation of materials and tools

To prepare a tool for manufacturing a product, you need to understand what the material and fasteners will be. Basic tools you will need:

- hammer;

- screwdriver;

- bent reinforcement (for attaching the structure to the base);

- stainless steel fastening parts;

- electric drill (if you are fastening the posts with concrete, you will need a mixing attachment);

- special coatings for metal that protect it from corrosion.

- measuring tool;

- welding machine (if necessary for connection);

- a hacksaw (if there are wooden elements), as well as a grinding tool;

- screwdriver;

- waterproof roofing fabric;

- angle grinder for cutting parts to the required length;

A model in the shape of the letter “A” would be practical; the load-bearing fasteners do not need to be filled with concrete. The crossbar is most often a metal pipe with a cable attached to it. The supports consist of channels or pipes. The work is based on the presence of gravity.

To create such a design you will need:

- copper wire;

- reinforcement 10 mm;

- cable or chain;

- handrails and seat slats;

- bolts and nuts “10”;

- pipe with a cross section of 60 mm.

- metal profiles with a section of 12x12 mm;

- two-inch pipes;

- corner "4";

Assemble the swing by placing and securing the supports. Metal plates are fixed at the top points, the crossbars are made of profiles. Consequently, the structure will have acceptable rigidity. The two bearing supports are connected by a welded plate. The slab must have a minimum thickness of 5 mm to withstand the required load.

The seat can be single or double. It is made of strips (40-70 mm thick) and rods, the units are fixed with bolts.

They have proven themselves well as load-bearing supports for PVC pipes. The pipes can withstand significant loads and are also easy to install.

The second option for making a swing

Pillars

For greater reliability, the sidewalls of the structure are recommended to be made in the form of the letter A. But the frame can also be assembled from single products that serve for support, and the required stability is given to it by the corners installed at the bottom. The most common option is when they first weld a base made of pipes in the form of a rectangle, to which two triangles installed vertically and a jumper are attached, thereby achieving visual compliance with the letter A. If we exclude the metal base, which turns the swinging device into a mobile structure, care must be taken about concreting racks.

Crossbar

The installed triangles are complemented by a crossbar. The structure created in this way is fixed using prepared trenches or holes, maintaining alignment in both planes. Then the recesses are filled with concrete, which needs to be given some time to completely harden.

Seat

Swings aimed at adults mostly look like a standard bench without legs. If such a device is intended for children, it is recommended to install a single or double seat.

Chains

Despite the fact that arranging suspensions from chains is an expensive pleasure, this must be done, since such structures are characterized by maximum strength, promote swinging and are caused by pronounced signs of wear, which allows you to notice critical wear in time. If the swing is aimed at children, small-gauge chains should be suspended to avoid the possibility of pinching fingers.

Painting

The final assembly of the structure must be completed by applying a special composition. This makes the assembled device more attractive and protects it from corrosion.

Rust converter

To prevent the destruction of metals, a rust converter is used, the application of which ensures the formation of a barrier film against aggressive environmental influences. Typically this composition is applied to the metal before painting.

Manufacturing and assembly of the structure

To make a garden or children's swing with your own hands, you need to choose a suitable design and decide what materials the structure will be made from. Then you should prepare the place where the swing will be located:

- level the site;

- add a “cushion” of gravel.

You will need to have the necessary tools and materials in advance. The support for a fixed swing can be made of the following materials:

- wooden beams;

- metal pipes.

- PVC pipes;

The latter will need to be welded in some places, so a special apparatus will be required.

From a metal profile

To create a structure from a profile you will need:

- side wall of the letter “A” configuration, consisting of two pipes secured by welding;

- a pipe that will be horizontal and will be used to hang the bench.

- quadrangular support frame;

Metal profiles today are a reliable material. It is also suitable for creating a profile pipe with a cross-section of approximately 200 mm, while the wall thickness should be 1 or 2 mm. The base of the seat can be made of a pipe with a cross section of approximately 20 mm. This will affect the smooth swing.

Fastenings are usually made in chains, so the length of the swing can be easily adjusted. The seat is also wooden, this material is quite functional.

Installation process:

- we connect the necessary parts by welding or special bolts;

- we connect the posts to the base of the swing, then screw the crossbars;

- for stationary garden swings you need to dig 4 holes;

- beams must be inserted into these holes and filled with concrete.

- sand the wooden elements (these will be seat parts);

- we cut out the elements consisting of a pipe (side posts, crosses, base);

Made from polypropylene pipe

Children's swings must withstand a load of at least two hundred kilograms. A cross-section of 50x50 mm is allowed, wall thickness is at least 1 mm. Swings for adults are made of tubes with a cross-section of 75 mm. The seat consists of rods and slats. Comprises:

- 8 metal corners;

- reinforcement with a cross-section of 16 mm and a length of 26 cm;

- wooden canvases.

- from a pipe 6.2 m long;

To make good supports, you will need two meters of pieces that will serve as cross supports, and you will also need a top crossbar. In addition, to assemble the fasteners, it is necessary to prepare four sections of 2.3 meters each. And two additional sections of one and a half meters to obtain the side nodes of the base.

Construction should begin with the supports; they bear the main load. Before starting work, the pipes must be cleared of dents. The two structures are welded in the shape of the letter “L”, they must be completely identical. The nodes are welded at an angle of 45 degrees, and the crossbar is fixed perpendicularly. Two basins are dug (up to 1 meter), the bottom is sprinkled with sand. Welded structures are placed in niches and filled with concrete. Wait three weeks for the concrete to “harden”.

Then fasteners or hooks are screwed to the crossbar, and the seat will hang on them. After installation is completed, the new structure should be painted. The seat consists of a metal structure, wooden or plastic beams and slats.

To make the “seat” soft, foam rubber can be placed under the upholstery.

Types of swings made of profiled pipes

Swing in the form of a sofa

The structure is designed for children's games and adult gatherings. In the first case, free-standing products are installed and placed in the playground area. The seat is equipped with a protective bar to protect the child.

There are models that have an extended seat. This option is more suitable for older children and adults. For relaxation of children and parents, a seat is made in the form of a sofa. This type does not involve swinging at high altitudes; families and children relax here after a hard day.

There is a swing-bed, which is made in the form of an ottoman on chains. They are usually made with a roof, sometimes covered with a mosquito net. Here you can put your child to bed after lunch, and sleep will come faster due to uniform rocking.

Portable swing

The design does not require a foundation, since it can be rearranged as needed. The area of the lower support is increased by welding a square base from the same profile pipe. Small-sized children's swings are made from a thin-walled profile to reduce the weight of the structure.

Portable outdoor models provide a seat for one child. Such structures are made folding, for example, the frame is rearranged separately, then a saddle with cables is hung. Often hangers are made with soft chain hangers, sometimes they use hard steel cables or are made of pipes.

Stationary swing

Swings with fixed legs

Fixed swings made from pipes are made with your own hands if you need large structures for constant use in one place.

In these options, all parts are made from professional pipes:

- vertical supports, horizontal beam;

- saddle hangers;

- seat frame, a wooden cover is placed on it.

The swing posts are placed at an angle to increase the force of resistance to the load. For several people, double racks are installed for the same reason. They are welded along the entire length on both sides of the profile; not a continuous, but an intermittent seam is allowed.

Care Tips

Before we talk about caring for swings, it is worth dwelling on the operating conditions of these structures. It was said above that such products are not recommended to be placed near communication lines. You will also need to make sure that there are no sharp protruding corners that can be easily trimmed.

As for the start, it does not cause much trouble; you just need to follow a few rules.

- If you treat the structure with enamel or varnish, this will extend its service life, but it is worth remembering that the varnish will only last a few years.

- Check the fasteners from time to time as the material wears out over the years.

- If the structure is made of metal, then such material must be protected from corrosion by special means. It is easy to find a rust converter in stores, thanks to which a protective film is formed.

Preparing the boards

After you have successfully welded the seat of a swing for two children (or adults), all that remains is to trim the joints and check the quality of the seam

When making a children's swing, attention to the quality of the seam should be increased. It is inspected and, if necessary, covered again

Boards are cut to the size of the base, the edges of which are rounded with a hand router or a simple plane and a hog file. The front board is also processed in this way from the outside.

Holes are made in the base for fastening the boards. They can be drilled with a drill or burned through by welding. It is necessary to burn from the inside. Metal deposits from the outside are cleaned by welding. The same operations must be performed to secure the boards to the back of the swing.

The boards are adjusted and secured using wood screws and checked to see if they fit well. Then they are removed, treated with impregnation and a layer of stain or paint is applied.

It is necessary to process parts from all sides so that the swing seats last longer. After applying the impregnation, you must clean them with sandpaper.