A do-it-yourself boat made from PVC pipes is a simple design.

Its production will cost very little, but you can get a lot of pleasure during the summer swimming season. You can make such a structure from plastic materials yourself. It's not a difficult job. PVC pipe is the most convenient option for constructing products with your own hands. These products are perfectly held together using glue or soldering.

Even if the boat gets damaged during use, there is no need to be upset. Such repairs on your own will not be difficult. Using the same glue, simply apply a patch to the damaged area.

To what has been said, it must be added that building such a boat with your own hands is a very interesting job.

It is recommended to start making a boat with the selection of a drawing. Based on them, the most convenient design is selected.

It’s a good idea to first make patterns of reduced sizes and glue such a structure from ordinary plastic bags. With this kind of work, you can “feel” the material, which means that working with full-scale sizes will be much easier.

After working out the patterns, they are increased proportionally. Craftsmen advise checking the compatibility of the workpieces by making the structure in natural dimensions from polyethylene.

This will, of course, take extra time, but it will be worth it. If any errors were made in the calculations, this will be clear at the initial stage, and there will be no need to spoil expensive materials.

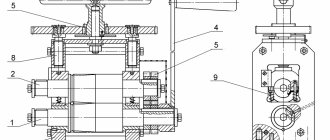

Connecting the edges of fiberglass sheets on stringers (a) and frames (b)

1 - fiberglass sheets; 2 - epoxy putty; 3 - stringer; 4 - nail; 5 - frame.

Then all irregularities are filled with epoxy putty and the body is allowed to stand for two to three days. After this, the body can be sanded, and then covered with additional layers of fiberglass to the desired thickness of the skin. When applying the last layer of fiberglass, a coloring pigment is added to the epoxy resin. Next, the skin is sanded, if necessary, it is painted, turned over and work begins on the inside of the body.

The boat I built in this way has been sailing for 8 navigations. Its length is 8.5 m, side height 1.2 m, width 2.6 m; engine - "ZMZ-53". During operation, there were several cases of collisions with driftwood, and although the set was damaged by strong impacts, there were no leaks. The kit does not lag behind the skin, and repairs after encountering a snag do not require much time. Now I’m finishing the construction of a ten-meter yacht using the same method. There is no doubt that the resulting structure will be light, strong, and durable.

L. Nefedov, Perm.

Share this page on social media. networks or add to bookmarks:

Materials for making a boat

The Internet is teeming with a variety of creative ideas that can easily be brought to life. By entering any query into a search engine, a person quickly receives the answer he is interested in.

And having decided to build a means of floating on the water, you will easily find a lot of ideas that, if desired, can be brought to life. So, what can you make a boat from? It can be made from:

Each listed material is difficult to use, because the density is different, and therefore the quality is different. But it is worth remembering that each material has its pros and cons. Therefore, the choice of material directly depends on the service life of the product:

- For example, the most durable material is wood. It is more suitable for long-term swimming on the water and can last for seven years. It is worth remembering that you need to take a durable tree. It is best to use oak. So there is a high probability of high-quality production.

- Plywood is no longer as reliable as wood. This will be determined in its subtlety. But, if you don’t go fishing very often and want to save money on manufacturing, then plywood is an excellent choice.

- As for bottles, many people ask a very logical question: how to make a boat out of bottles? Many will think that this is not real at all. But despite all the doubts, the result will be amazing. It will be easy. But in the case of manufacturing, you need to make every effort to ensure that the result of your work does not fall apart while climbing onto the water.

- Aluminum is also an excellent material. It is reliable and can last a long time. But production from such material will take a lot of time and effort. Therefore, many people prefer a wooden base.

The last material is very common. After all, all purchased swimming equipment is made from rubber. It floats well and can withstand a lot of weight.

But you need to be careful during production, because one puncture will ruin it. Time, effort, money will be wasted. The process requires complete concentration and maximum attention.

Cart

Unlike a boat, which will take a little time to create, a boat cart made from PVC pipes can be made quickly. It is intended for transporting a boat made of PVC pipes with an engine and adjacent cargo.

The presence of a trolley makes transporting the boat much easier. Having a do-it-yourself trolley, you can do the transportation without any outside help or stress.

In the provided photos and videos, you can see various options for these mechanisms. After considering them, you can choose the most suitable option for building with your own hands.

The dimensions of the cart depend on the dimensions of the boat. And when calculating them, you need to keep in mind that the width of the cart should be such that the watercraft fits comfortably on it.

To create such a design with your own hands, you need to prepare a pipe with a volume of 32 mm. Experts recommend choosing products reinforced with fiberglass

You should also stock up on appropriate fasteners for the pipes (couplings and crosses). You will also need a pair of wheels and a steel rod.

First, an axle is made from tubes with an inserted steel rod. Wheels are inserted onto it and secured with brackets. Next, a frame is made from the tubes, which is placed on supports above the axle.

On the frame it is necessary to provide fastenings for a rope with which the floating device will be secured to the trolley. That, in fact, is all the work.

Some more details

Now it’s clear how to make a boat from PVC pipes. This work will require a lot of patience and will take quite a bit of time, but in the end result you can get great pleasure from such an addition to your vacation on the water as an excellent boat made by yourself.

For ease of swimming you will need oars. They are also not difficult to make with your own hands. A thin PVC pipe is perfect for this.

It will need about two meters. Holes must be drilled at each end of the pipe roll. Then two strips 0.4 m long are cut out of acrylic.

These strips are attached to plastic tubes with self-tapping screws. It is not recommended to tighten the screws very tightly, because the acrylic may burst. It is recommended that the lower part of the oar be slightly rounded.

For greater stability of the product, outriggers can be attached to its side parts. Their role can be played by two large plastic bottles on remote bars.

There are advantages to this addition, such as the creation of free space for storing catch or any other small items. But this solution also has its downsides; it is a little more difficult to row on such swimming structures due to lack of space.

A real fisherman does not give up fishing either in winter or in bad weather. When fishing in the summer, an awning can protect you from the scorching rays of the sun and from pouring rain while afloat. With such protection, the river trip will not be hopelessly ruined.

Summer is coming, and that means swimming season. It would be nice to make a simple boat using plastic pipes. It will take approximately one month to create such a boat, and a school swimming pool will be suitable for testing it.

Step 1. Materials needed

Wooden base

For many centuries, people have used wood as a means of transportation on the water surface. At first these were simple structures in the form of small platforms, later a boat appeared, the production of which took a long time.

After all, it must be of high quality for the safe transportation of cargo. Nowadays, if desired, anyone can reproduce the remedy at home.

A simple step-by-step plan will teach you how to make a wooden boat. It is necessary to prepare in advance long, wide boards that will serve as the sides of the shuttle. They must be dry, smooth, and free of cracks.

After preparing the base material, it needs to be processed for easy fastening. The edges of the boards must be cut evenly so that when assembled, the boards touch each other tightly. Next, we begin to make a vehicle. You need to start from the bow. We cut out an additional board that will hold the sides in the middle.

After finishing work on the sides, you need to build seats. The process is very simple, so it won't take much time. Wooden boards must be nailed to the sides. After this, the bottom should be installed. It may be iron.

We cut out the desired shape from a sheet of iron and, thanks to densely driven nails, fasten it to a wooden base. The boat is almost ready. All that remains is to attach the iron chain, which will serve as the basis for the anchor.

Making a boat from plywood

The construction plan for how to make a boat from plywood will be slightly different from the previous one. How to make a boat with your own hands, drawings and descriptions will become a reliable assistant during the process; complete information on the drawings can be found on the Internet.

Take a large sheet of plywood and draw the outlines of the product on it, relying only on the drawings. Then cut it out. The layout of the product is ready, all that remains is to secure everything correctly. The work needs to start from the sides in exactly the same way.

If you want to attach a motor, the tailgate must be strengthened. After fastening the bolts well, attach the bottom. You need to use glue and resin. You shouldn’t regret applying the listed products, but you shouldn’t overdo it either. After applying them, you need to wait until they dry completely. Here is the boat almost ready, you just need to paint it at your discretion.

Frame

The boat frame made of PVC pipe is the basis of the basics. The integrity of the structure will depend on its strength. You can learn how to build a frame correctly in the videos provided.

If you approach this issue irresponsibly, the constructed structure will fall apart the first time you try to launch it into the open water.

After detailed development and verification of the drawing, practical work on creating the frame can begin. You can secure the frame using the methods already suggested above, or you can use a soldering iron for plastic products.

Working with such tools is not difficult. Even a person who has no experience in this field can cope with these works. Soldering irons come with instructions that describe the entire procedure in detail.

It is not recommended to buy this tool for a one-time job to weld a frame, justifying it as economically unprofitable.

It is better to use a rented device to attach a frame made of plastic pipes. This service is offered by stores that sell soldering irons.

A frame made from blanks soldered with a soldering iron will last a long time. In this case, each joint of the frame will be highly durable. This way you can make a very durable structure with your own hands.

If any difficulties arise during work, video materials will help you solve the problem of how to properly make a frame from PVC pipes.

Rubber dinghy

The answer to the question: how to make a boat with your own hands, drawings will be the first answer. Thanks to them, the product will turn out to be the correct shape. Therefore, the first thing you should do is draw drawings, calculating the smallest details.

After this, we cut out a boat of the specified dimensions from a sheet of plywood. Additionally, we will need boards to securely fasten the bottom and a tarpaulin for covering. These materials must be connected to each other using the same glue and resin. Be sure to give the glue time to set, otherwise the structure will turn out flimsy. And your efforts will be wasted.

After this, cover the product with a tarpaulin, tightly attaching it to the boards. Remember, the design must be wide. This way you will get a homemade boat. It will not be very similar to the rubber one that is sold, but it will provide you with softness and comfort.

For a better understanding of the manufacturing process, you can see how to make a PVC boat with your own hands. There they will explain the principle of operation using a clear example. After all, reading and seeing an example, repeating actions, are completely different things.

But to be effective, it’s worth reading the detailed description and watching the video tutorial. This way you can quickly understand how to make a rubber boat correctly, which can serve for many years.

Airboat

Having seen photographs on the Internet of how a boat is made from bottles, many are surprised, asking a natural question: how to make a homemade boat from plastic bottles or how long can it be used?

The manufacturing principle is so simple that even a ten-year-old child can construct it. For production you will need a lot of plastic bottles. They must be in perfect condition, without cracks or holes, so as not to allow water to pass through.

The quantity depends on the desired size of the vessel. Also, the bottles must have lids to prevent water from entering inside and making them heavier. The plastic material must be laid out in the shape of a vessel, carefully secured together with glue.

Here is the swimming aid ready. It is very cheap to produce, but not very high quality. There is a high probability that if you catch on a branch you can pierce the bottle, thus damaging the structure.

Design selection

From plastic pipes you can make:

- a regular single or double boat (picture above);

- a catamaran-type boat that can be propelled by an oar, small motor, or pedal drive.

Catamaran boat with oars

The advantages of a catamaran over a regular boat are:

- minimum amount of materials. A catamaran made of PVC pipes may not be sheathed, equipped with a keel or other structures that ensure comfortable use;

- light weight, which makes transportation easier;

- strength and reliability achieved through the balance of the craft;

- the ability to develop high speed;

- possibility of installing several seats.

Aluminum ship

Having learned the principle of production of previous boats, it is not difficult to guess how to make an aluminum boat. The only difference is in the material from which the vessel will be made. In terms of strength, it can easily be placed in second place after wood.

And if done well, it can last a lifetime. When doing this, remember that you need to attach the materials efficiently and firmly. Because life depends on the quality of work.

DIY anchor

The anchor is the main element of a floating craft. After all, it helps to stay in one place for a long time, not allowing the current to carry the ship away. In order to attach an anchor, you need to drill a hole in the back of the boat, stretching an iron chain, which will become the basis for the anchor.

Next you need to attach the load itself. It must be a large piece of iron that can stop the boat. It will need to be attached to the chain by welding. Ten minutes - the anchor is ready. This is the easiest way to make a boat anchor with your own hands.

Assembly of the finished product

The weight of the finished product will depend on the initially selected length and width. The more people the boat has to support, the heavier it will be, but at any size one person should be able to handle the assembly themselves. When folded, it will look approximately as shown in the photo below:

The process of assembling it is simple and takes no more than ten minutes, you can do it alone, you may need a spacer and a little skill for convenience. In the photo below you can clearly see the mounts for the cans.

Banks not only serve as seats, but also provide rigidity to the boat, so special attention must be paid to the quality of their fastening:

The nose is closed with a special pad that will protect against splashes of water inside. vessel:

Now we insert the oars into the oarlocks or install the motor and the boat is ready to sail!

Types of boats based on materials of manufacture

The following materials are used in the construction of boats:

- Rubberized fabric;

- Plastic construction parts;

- Steel structural elements;

- Wooden structure;

- Plywood construction.

Inflatable boat

Rubberized fabric is used in the manufacture of inflatable boats. Rubber or polymer boats have poor stability and do not withstand low temperatures and physical impact, so damage in deep water results in major troubles. But there are also advantages - they are convenient to store and easy to transport due to their compactness when folded.

Inflatable boat

Plastic boats

These are visually attractive watercraft. They are produced in various color options. Proper operation of a plastic boat will repay the owner with durability.

Plastic boats

Catamaran project

There are real projects available that can be implemented in a small apartment, using only hand tools, ensuring high mobility of the product (no parts longer than one and a half meters - can be transported for free in any public transport and on an airplane), its low weight, ease of assembly and disassembly designs, the necessary strength and reliability.

So, if you have finally decided to make a collapsible sailing type, then you should look in the specialized literature for drawings of sailing catamarans that correspond to your choice. Believe me, it's not that difficult.

Let's consider a sailing catamaran based on two inflatable rubberized bags, which when inflated form two “cigars” with a diameter of 40 cm and a length of 280 cm, weighing 12 kg with sails and oars, which can easily support four crew members, providing them with sufficient comfort for work and rest and fishing. Each crew member accounts for only 3 kg of boat weight, and the ship’s unsinkability, convenience and excellent navigability have been tested in practice by dozens of short and long trips along the rivers and lakes of the central part of European Russia. These trips have shown that a catamaran design based on bag-type floats, which easily change their shape, overcomes obstacles and shallows much more safely, where kayak-type structures based on a rigid frame often damage the rubberized fabric, forcing repairs in the field.

Wooden boats

The service life of wooden boats is shorter than that of plastic ones. Wooden boards are used in production. For this type of boat, constant care using a moisture-repellent composition is important. Before launching, the boats are kept in the water for some time to maintain geometric parameters.

Wooden boats

Plywood boats

Due to its moisture resistance, great strength and resistance to stress, plywood is the most optimal of all wood materials for building a boat. The only difficulty that manufacturers face is the poor bending flexibility of plywood. As a result, smooth lines in the designs of plywood boats are very rare.

Plywood boats

Metal boats

Such boats are built using duralumin as the main building material. This material is wear-resistant and durable in use. You can use stainless steel in construction, but this makes the boat very heavy and makes its transportation problematic.

Metal boats

Building a plywood boat

Before starting work, it is worth deciding on the size of the future watercraft.

When purchasing material for building a boat (in this case, plywood), preference should be given to moisture-resistant options. They have a long service life and the boat will need to be repaired much less often. For the bottom, choose 12 mm plywood, for the sides - 10 mm.

Pattern and cutting out parts

Having prepared the basic material, we begin the production of parts. We do this using cutting. Large sheets of paper are suitable for the pattern (wallpaper will come in handy here). The dimensions of the pattern must be identical to the actual dimensions of the parts. A jigsaw is ideal for cutting plywood.

Pattern and cutting out parts

Bottom gluing

Standards for plywood sheets will not allow for a solid bottom. You will have to glue it together from several components. The cream used for these purposes must have moisture-repellent properties. The gluing operation itself takes place using specially prepared strips of plywood 100 mm wide.

Connecting boat parts

The stiffening ribs are made from birch beams. They are glued inside the boat at a certain angle. The parts are connected to each other with steel wire or nylon thread, which are threaded through specially made holes. Without exception, all joints are glued with fiberglass using epoxy resin (or moisture-resistant glue). Tape all joints both inside and outside the structure.

Connecting parts

Assembly order

Assembly begins with the side parts (stern, bow and sides). In this case, it is necessary to ensure the correct spacing, the correct location of parts and corner connections. The stiffeners can be strengthened with self-tapping screws.

By analogy, we attach the bottom to the body. The mooring beams are glued to the outer upper side parts. It will prevent the destruction of the sides during the mooring process.

An important part of the boat is the keel, which is responsible for the stability of the vessel and its correct cornering. It is fixed in the center of the bottom, and consists of several slats to increase the strength of the boat and stability afloat. The rear part of the stern is reinforced using special impregnations.

Having lowered the boat into the water, check the absence of leaks and the carrying capacity. After removing the problems (if any), the boat is painted in several layers with oil paint.

How to build a boat at home. Plywood boat Charon construction history

How to make a PVC boat with your own hands

The dream of any avid fisherman is a light, maneuverable boat that can be easily transported to your favorite lake and go fishing for your own pleasure. In principle, you can make such a compact folding PVC boat with your own hands and enjoy fishing.

The boat is assembled from polypropylene or PVC, so it weighs only 40 kilograms. The height of the boat sides is approximately 50 centimeters, and the width reaches 1.2 m, and the total length of the boat is 3 meters 75 centimeters. Can be easily transported in the trunk of a car.

You can install a motor on the boat, and then it reaches speeds of up to 12 km/h (with a motor power of 3.5 hp). It takes about 10 minutes to assemble the boat on the shore. If the engine suddenly stalls, which happens often, the boat glides easily on the oars.

Polypropylene

| Weight, kg): | 120 |

| Side height (cm): | 60 |

| Length(cm): | 375 |

| Max. load capacity (kg): | 300 |

| Max. motor power (l/s): | 15 |

| Material: | polypropylene |

| Passenger capacity: | 3 |

| Width(cm): | 148 |

The boat is intended for hunting, recreational fishing and boat trips on rivers, lakes and in coastal areas of reservoirs at a distance from the shore of no more than 1.6 km, with waves no more than 0.6 m high.

It differs from 370.01 in chrome plated cleats and handrails.

| Brand: | Technopolymer |

| Weight, kg): | 120 |

| Side height (cm): | 60 |

| Length(cm): | 375 |

| Max. load capacity (kg): | 300 |

| Max. motor power (l/s): | 15 |

| Material: | polypropylene |

| Passenger capacity: | 3 |

| Width(cm): | 148 |

| Brand: | Technopolymer |

| Weight, kg): | 280 |

| Side height (cm): | 73 |

| Length(cm): | 480 |

| Max. load capacity (kg): | 400 |

| Max. motor power (l/s): | 50 |

| Material: | polypropylene |

| Passenger capacity: | 4 |

| Width(cm): | 180 |

| Brand: | Technopolymer |

| Weight, kg): | 280 |

| Side height (cm): | 73 |

| Length(cm): | 490 |

| Max. load capacity (kg): | 450 |

| Max. motor power (l/s): | 60 |

| Material: | polypropylene |

| Passenger capacity: | 5 |

| Width(cm): | 180 |

Swimmer 450 is easy to control and easy to plan. Excellent for both fishing and family recreation. A boat of this size is very convenient for storage and transportation.

It differs from 450.01 mainly in better technical equipment.

| Brand: | Technopolymer |

| Weight, kg): | 280 |

| Side height (cm): | 73 |

| Length(cm): | 480 |

| Max. load capacity (kg): | 400 |

| Max. motor power (l/s): | 50 |

| Material: | polypropylene |

| Passenger capacity: | 4 |

| Width(cm): | 180 |

Swimmer 490 is easy to control and goes on planing easily. Excellent for both fishing and family recreation. A boat of this size is very convenient for storage and transportation.

The difference with 490.01 is better technical equipment.

| Brand: | Technopolymer |

| Weight, kg): | 280 |

| Side height (cm): | 73 |

| Length(cm): | 490 |

| Max. load capacity (kg): | 450 |

| Max. motor power (l/s): | 60 |

| Material: | polypropylene |

| Passenger capacity: | 5 |

| Width(cm): | 180 |

| Brand: | Technopolymer |

| Weight, kg): | 340 |

| Side height (cm): | 93 |

| Length(cm): | 550 |

| Max. load capacity (kg): | 500 |

| Max. motor power (l/s): | 90 |

| Material: | polypropylene |

| Passenger capacity: | 5 |

| Width(cm): | 227 |

Swimmer 550 is a light and easy-to-handle boat with a spacious cockpit for passengers and the captain. In the bow, the boat is equipped with a folding ladder for convenient boarding of passengers from an unequipped shore.

It stands out against the background of 550.01 due to its improved technical filling.

| Brand: | Technopolymer |

| Weight, kg): | 340 |

| Side height (cm): | 93 |

| Length(cm): | 550 |

| Max. load capacity (kg): | 500 |

| Max. motor power (l/s): | 90 |

| Material: | polypropylene |

| Passenger capacity: | 5 |

| Width(cm): | 227 |

Polypropylene is a very strong yet lightweight polymer material that offers an innovative weight-to-strength ratio. This level of strength allows the vessel to be unpretentious to operating conditions (for example, mooring to any shore or pier without fear of being left without sides or bottom), unpretentious to storage conditions and maintenance.

You can learn more about the manufacturing technology of the boats presented in this section here.

Necessary materials for a PVC boat

In order to make such a boat with your own hands, you will need polypropylene sheets, three boards, several hundred bolts, a bottle of silicone sealant, a jigsaw and a screwdriver. It takes about a week to assemble the model, but the result is worth it.

Polypropylene is a sheet material used for 5mm swimming pools. They are sold by companies involved in the construction of swimming pools and water tanks - the price for 1 m2 is about 750 rubles and more. This boat took 8m2 + wood for seats, fastenings and a transom for the motor.

The dimensions of the boat may be smaller if solo fishing is planned.

Approximate cost calculation

Now, as always, the most pressing question is: how much will such a boat cost? Below is an approximate calculation of the cost of the materials used:

A folding boat made of polypropylene, made by yourself, will cost much less than the same industrially manufactured one. A good mood, excellent fishing, hunting or travel are guaranteed.

Source

From experience in making PVC boats

When assembling a boat, you can use welding rather than bolts, but then if it breaks, it will be difficult to replace the damaged part of the boat.

If bolts will be used in assembling the boat, then it is necessary to make a edging. Polypropylene is a fairly strong material, and it is simply impossible to bend it, but if you make a edging, it will be easy to bend. It is enough to use a regular cutter to make indentations of about 3 millimeters.

You need to step back from the edge so that there is enough space to place a 15 mm bolt with a washer.

When working with a cutter, you must be careful, especially when the sheet is just starting to be cut or at the end. These areas are critical, because the cutter can slip and cut right through the sheet.

The cut sheet can be easily bent and its shape changed; no deformation of the material will occur. True, it is not advisable to use glue to attach boat seams; it will leak anyway. Either bolting or welding will be required.

When you have made the boat, you can start making an anchor for a PVC boat with your own hands. But more on that in the next article.

We wish you a pleasant time with your fishing rod. We are waiting for your feedback.

Production process

To make a regular boat from large-diameter HDPE pipes or other types of pipes, you need:

- make a boat frame;

- sheathe the pipe frame with any waterproof material;

- make your own from pipes and plastic or buy oars.

- make and install a keel for the boat, facilitating the steering process;

- make a cart for transporting watercraft. A boat trolley made of pipes is made in accordance with its overall dimensions.

Means of transportation

Frame assembly

To make a frame from sewer pipes, at the first stage you will need to develop a drawing of the future structure. The shape and dimensions are not of fundamental importance, therefore they can be determined by the user independently, based on the level of comfort during use.

The boat can be equipped with one or more seats. To give the structure additional strength and stability, it is more advisable to equip the bottom with a rigid base, for example, a wooden flooring, fastened with clamps (ties).

When assembling the frame you can use:

- welding method, characterized by a large margin of strength and tightness;

- duct tape. The least durable design, characterized by speed of production.

Boat base

After the frame is completely assembled, you can begin installing the seats. You can also make your own boat seat from PVC pipes. Most often used:

- chair seats;

- wooden boards;

- metal plates.

Sheathing

To cover the frame you can use:

- tarpaulin. The material is more durable and durable, but also more expensive;

- transparent polyethylene film. The material is less durable, but the finished boat looks more original.

To fasten the selected cladding material, the following are used:

- adhesive tape;

- plastic clips;

- plastic rings.

Boat ready for use

You can build other designs of homemade boats, which will be based on pipes. It all depends on the builder’s imagination and his ability to work with these materials.