Pipeline fittings are used by enterprises in the energy industry, housing and communal services organizations, in the metallurgical, chemical, food and other industries.

Table of types and classifications of pipeline valves.

Shut-off, phase-separating, protective, distribution, high-pressure, shut-off and control valves act on the flow area, determine changes in the flow of substances, and actually control them. The task of shut-off valves is to start and stop the flow of the working medium. Timely diagnostics and high-quality repair of valves ensure efficient operation of the entire system and reliable fixation of the extreme positions of the unit (“closed”, “open”).

Engineering communications service Heating, water supply, drainage, sewerage systems

around the clock tel: 8

INSTALLATION, REPAIR, MAINTENANCE, MODERNIZATION, REPLACEMENT

For electrical cable

| Pipe diameter | Wall thickness | Price for 1 p.m. VAT included |

| TU 6-49-53883187-01-05 SDR 17.6 | ||

| 16 s | 2 | 9,43 |

| 20 s | 2 | 12,10 |

| 25 s | 2 | 15,48 |

| 32 s | 2 | 20,26 |

| 40 s | 2,3 | 27,71 |

| 50 s | 2,9 | 42,99 |

| 63 s | 3,6 | 63,88 |

| 110 s | 6,3 | 149,75 |

| 160 s | 9,1 | 315,88 |

| 225 s | 12,8 | 619,44 |

| 315 s | 17,9 | 1890,00 |

| 400 s | 22,7 | 3138,75 |

For electrical cable

Incomplete flow blocking

The cause of this malfunction may be:

- Scale on the contact surfaces of the valve and body

- Mechanical damage to contacting surfaces and housing in the form of scratches or corrosion pitting

- Wear of the contacting surfaces of the valve and body. This is especially true for rubberized structures

To repair the valve, the valve is dismantled, the valve - a solid or composite wedge or disk - is removed, and the contacting surfaces of the valve and the body seats are inspected. If scale or traces of rust are detected, they must be removed and their wear and the extent of mechanical or corrosion damage assessed using cleaned contact surfaces. If repair is possible for non-rubber-coated structures, it is necessary to mutually grind the contacting surfaces of the valve and seat with diamond-containing pastes. In case of damage to the rubberized sealing surfaces, it is advisable to replace parts, since high-quality repairs of such surfaces cannot be carried out by hand. Upon completion of the repair, the valve is reinstalled and the nuts of the rubber connections are tightened with the tightening torque recommended in the accompanying documentation.

Pressure water

| Pipe diameter | Wall thickness | Price for 1 p.m. VAT included |

| TU 6-49-53883187-01-05 SDR 17 | ||

| 16 t | 2 | 13,75 |

| 20 t | 2 | 16,82 |

| 25 s | 2 | 21,46 |

| 32 s | 2,3 | 31,61 |

| 40 s | 2,4 | 41,76 |

| 50 s | 3 | 65,25 |

| 63 s | 3,8 | 103,96 |

| 110 s | 6,6 | 291,82 |

| 160 s | 9,5 | 608,82 |

| 225 s | 13,4 | 1206,46 |

| 315 s | 18,7 | 2349,49 |

| 400 s | 24 | 4114,22 |

Pressure water

Manual rotation of the flywheel is difficult or impossible

Problems with the rotation of the flywheel most often arise due to jamming of the valve by scale formed as a result of irregular maintenance of the valve. To repair such a malfunction, it is necessary to remove the cover by unscrewing the fastening nuts, then remove the shutter and clean the contacting surfaces of the shutter and the body seat from scale to bare metal without damaging it. If necessary, grinding in of contacting surfaces is carried out. The repair is completed by reassembling the valve and tightening the nuts of the rubber connections with the recommended tightening torques.

PVC pipe

| PVC pipe 160x3.6x1,000m | PC | 264,37 |

| PVC pipe 160x3.6x2,000m | PC | 503,75 |

| PVC pipe 160x3.6x3,000m | PC | 775,41 |

| PVC pipe 50x3.2x0.500m | PC | 42,30 |

| PVC pipe 50x3.2x1,000m | PC | 70,68 |

| PVC pipe 50x3.2x2,000m | PC _ | 131,85 |

| PVC pipe 110x2.7x1,000m | PC | 104,87 |

| PVC pipe 110x2.7,000m | PC | 195,12 |

| PVC pipe 110x2.7,000m | PC | 298,25 |

PVC pipe

Gate valve and its varieties

The flow of gas, steam or liquid is regulated by the most common type of shut-off valve - a valve. Devices can be conditionally classified according to several characteristics.

Valves are distinguished by type:

The sealing surfaces of the parallel gate valve are parallel to each other.

- full bore;

- narrowed (the diameter of the pipeline exceeds the diameter of the hole in the seal ring).

According to the shape of the gate valves, valves are distinguished:

- wedge;

- parallel.

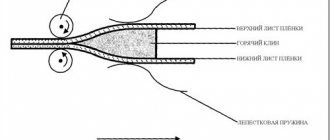

The peculiarity of wedge valves is to stop the movement of the flow of substances by progressively turning the valve perpendicular to the main flow of the transported substance. The sealing surfaces of the wedge valve are located at a certain angle relative to each other. All types of wedges are made of high-alloy steel. Application - transportation of ammonia (liquid and gaseous), water vapor and water, non-aggressive petroleum products.

The sealing surfaces of the parallel gate valve are parallel to each other. There are single-disc (gate) and double-disc valve valves.

Depending on the type of spindle movement, there are valves:

- with a rotating spindle (translational-rotational and translational movements);

- with retractable rod and spindle (rotational movements only).

Gate valves with a rotating spindle are used in pipelines where it is necessary to ensure frictional lubrication of the running nut and spindle and there is no threat of corrosion of the assembly. Valves with a rising stem are higher than rotating ones; due to their technical characteristics, they are used in all other systems.

A cast iron valve is used to start and completely stop the flow of substances. The maximum operating temperature is 225°C.

Valves are classified according to the type of material:

- steel;

- cast iron

A steel gate valve blocks movement in the pipeline. Permitted working substances are steam, water, non-aggressive petroleum products in gaseous and liquid form. They are used to work with various levels of pressure and passages in temperate climates along the entire length of the pipeline.

A cast iron valve is used to start and completely stop the flow of substances. The maximum operating temperature is 225°C. Allowed substances are steam, petroleum products, oil, water. Installation on horizontal and vertical pipelines is allowed, taking into account the installation features.

Both types of valves belong to the category of repairable valves with a forced service life.

Heat loss calculator

Calculator for the number of radiator sections

Heated floor calculator

A separate type is a hose valve, which consists of an elastic pipe placed in a flanged protective housing. There is completely no contact with the working environment. The principle of operation is one-sided or two-sided overlap of the elastic hose (pinching). Application: transportation of abrasive pulps, oil products, sludge, aggressive substances. The temperature of the medium should not exceed 110°C, and the pressure in the pipeline should not exceed 6 kgf/cm2.

How to adjust the balancing valve in a heating system

Setting up a mechanical balancer

Before setting up the balance of the radiator network, you need to study the instructions for the valve, which are included when purchasing it. It indicates an adjustment scheme; if the user installs everything correctly, he can actually reduce the cost of thermal energy. The valve can be adjusted in two ways.

The first way to adjust the valve

This is the simplest and most proven adjustment option, which is recommended by experienced thermal regulators in water heating networks. To do this, you will need to divide the number of valve revolutions by the number of batteries installed in the heating circuit around the perimeter of the room. This technique makes it possible to correctly determine the step of the tuning algorithm. The method consists of closing all the valves in the reverse order - from the outermost to the first battery in relation to the heating source.

For example, for a dead-end circuit with 4 radiators equipped with mechanical balancing valves and a 4.5-turn spindle adjustment:

4.5:4 = 1.1 turns

Opening diagram:

- The first balancing valve is 1.1 turns.

- Second balancing valve – 2.2 turns.

- Third balancing valve – 3.3 turns.

- The fourth balancing valve is 4.5 turns.

The second way to configure the balancer

There is another, very high-quality method of balancing. It runs much faster, and contains the ability to take into account some of the specific location of the battery. The only thing you need to do this is a contact thermometer.

The complete process goes like this:

- Open all the valves and allow the network to enter temperature equilibrium with the operating temperature, for example, 80 C.

- Measure the temperature of all heating devices.

- Eliminate the difference by shutting off the first and middle taps. The end valves are not adjustable.

- Typically, the first valve turns no more than 1.5 revs, and the middle ones - 2.5 revs.

- Allow the system to reach temperature equilibrium for 20 minutes

- Temperatures are measured and valves are adjusted further if necessary.

Use, repair and diagnostics of valves

Installation and maintenance of devices must be performed by highly qualified specialists.

The use of valve valves in technological and transport pipelines at key and auxiliary enterprises of various types of industry, in energy systems, in gas, oil and water pipelines is due to the following technical characteristics:

- long service life under adverse conditions;

- low hydraulic resistance;

- resistance to significant loads.

Installation and maintenance of devices must be carried out by highly qualified specialists with a sufficient level of knowledge, permission to carry out a specific operation, and have the skills to use a specific type of valve.

The main cause of valve malfunction is damage to the surface of the sealing rings due to the ingress of foreign small particles (sand, scale, etc.), which disrupts the tightness of the structure and causes leakage of the transported substance. In addition to significant material losses, when transporting hazardous or corrosive substances through a pipeline with faulty components, damage to the environment can occur, and in the most difficult situations there is a threat to the lives of workers involved in the process.

At the end of the work, specialists test the components for tightness of seals and test the functionality of the device.

Timely diagnosis and repair of the technical condition of the unit affects the quality and efficiency of the system.

To troubleshoot, depending on the location of the damaged unit, observing safety rules, the valves are disassembled and, upon completion of work, assembled with standard tools in specially equipped workshops or directly in the pipeline system. The worker responsible for carrying out the work is obliged to ensure adequate protection of the threaded and sealing elements from damage and to prevent foreign particles from entering the cavities of the assembly. At the end of the work, specialists test the components for tightness of seals, valves, gasket connections, and test the functionality of the device.

Repair and dismantling of valves is prohibited if:

- there is pressure in the cavity of the valve or system;

- the medium remains in the device.

It is unacceptable to use knots to regulate flow.

LLC DESIGN PRESTIGE

When is the best time to replace batteries?

So, let's start, first let's look at the simplest case when the batteries need to be replaced during apartment renovation.

It is best to replace batteries at the stage of finishing the rough finishing, that is, when the walls have been plastered and the screed has been poured. It often happens that an old heating device (convector or cast iron radiator) prevents you from plastering the wall behind it; in this case, you need to plaster wherever possible around the old radiator, so that the radiator installer understands what level the wall is at and installs the radiator as the required distance from the wall and parallel to it. Plaster the space behind the radiator by removing the new radiator after installation. You should also understand the technological process that first the radiator is installed on the brackets, blanks of new bends are attached to it on the union nut of the ball valve, and only then the bends are welded to the riser. And not vice versa. The reason is the need for clear alignment of the radiator outlets and collectors. An example of a job I reworked that did not follow the required workflow.

Boiler room maintenance cost

Technical (service) maintenance of the boiler room

| Name of works | Volume | Price |

| Service contract for floor-standing boiler (gas, diesel) up to 60 kW | with 1st scheduled departure | from 14 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) from 60 to 170 kW | with 1st scheduled departure | from 20 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) up to 60 kW | with 2 scheduled trips | from 22 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) from 60 to 170 kW | with 2 scheduled trips | from 30 000 ₽ |

| Service contract for wall-mounted gas boiler | with 1st scheduled departure | from 10 000 ₽ |

| Service contract for wall-mounted gas boiler | with 2 scheduled trips | from 15 000 ₽ |

| The exact cost is calculated after check-out | engineer |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Boiler room repair, diagnostics and prevention

| Name of works | Volume | Price |

| On-site inspection and diagnostics (without repair) | up to 50 km from MKAD | from 3,500 ₽ |

| On-site inspection and diagnostics (without repair) | from 50 to 100 km from MKAD | from 5,500 ₽ |

| Cleaning the burner (atmospheric) | power up to 60 kW | from 2,000 ₽ |

| Cleaning the burner (supercharged) | power up to 60 kW | from 3,500 ₽ |

| Cleaning the burner (atmospheric) | power from 60 to 170 kW | from 8,500 ₽ |

| Cleaning the boiler combustion chamber | power up to 60 kW | from 4,000 ₽ |

| Cleaning the boiler combustion chamber | power from 60 to 170 kW | from 6,000 ₽ |

| Checking and pumping up pressure in the expansion tank | without dismantling work | from 2,500 ₽ |

| Checking and pumping up pressure on the expansion tank | with dismantling and installation | from 4 500 ₽ |

| Refilling the heating system with a pump | system volume up to 200 liters | from 3 000 ₽ |

| Replacement of heating element, pump, heat exchanger, with coolant drain | for a unit | from 3 000 ₽ |

| Conversion of a gas boiler to liquefied gas | for a unit | from 3 000 ₽ |

| Burner settings | gas / diesel | from 2 500 ₽ |

| The exact cost is calculated after check-out | engineer |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices.

The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity. One of the conditions for the uninterrupted and long-term operation of modern equipment is timely professional maintenance. Heating equipment is no exception. Moreover, being subject to constantly changing weather conditions, the operating mode of the heating system is dynamic, therefore, some components (for example, circulation pumps) are constantly switching, which leads to additional loads.

To eliminate or minimize emergency shutdowns, it is necessary to regularly service the heating system.

This is usually done once a year before the start of the heating season..

Due to the complexity of the heating system, servicing should be carried out by experienced professionals.

Heat consumption for ventilation

To find out how much heat a private house loses as a whole, you need to add up the losses of all its rooms. But that’s not all, because we must also take into account the heating of the ventilation air, which is also provided by the heating system. In order not to go into the jungle of complex calculations, it is proposed to find out this heat consumption using a simple formula:

Qair = cm (tв – tн), where:

- Qair – required amount of heat for ventilation, W;

- m – amount of air by mass, defined as the internal volume of the building multiplied by the density of the air mixture, kg;

- (tв – tн) – as in the previous formula;

- с – heat capacity of air masses, is taken equal to 0.28 W / (kg ºС).

To determine the heat demand for the entire building, it remains to add the value of QTP for the house as a whole with the value of Qair. The boiler power is taken with a reserve for the optimal operating mode, that is, with a coefficient of 1.3. Here you need to take into account an important point: if you plan to use a heat generator not only for heating, but also for heating water for domestic hot water supply, then the power reserve must be increased. The boiler must operate effectively in 2 directions at once, and therefore the safety factor must be taken at least 1.5.

Repair technology for shut-off valves (gate valves)

- Disassembly, cleaning, detection of defects.

- Restoration of the body. Anti-corrosion treatment is carried out, grooves are machined under the sealing elements, and surfacing is performed.

- Elimination of defects in the cover and body by sampling metal.

- Restoring the tightness of the unit. Sealing elements are fixed in various combinations, depending on the type of valve. Used seats and gates are removed and new ones are installed.

- The spindle is restored by surfacing, and the threads are calibrated.

- Complete restoration of the stuffing box assembly by replacing the sealing elements (bearings, seals, cuffs, pressure and support rings).

- New disc springs, O-rings, shields and discharge valve are installed.

- A new steering wheel is being restored or machined.

- Tests (hydraulic or pneumatic) and diagnostics for tightness and strength of the unit are carried out.

- The product is preserved and painted.

Each of the repaired products undergoes several stages of control: visual, technical and instrumental, in accordance with the legislative acts of the Russian Federation and the requirements of manufacturing enterprises.

The cost of repair work to restore valve valves in most cases ranges from 30 to 50% of the original cost of the product. At the same time, technical and operational characteristics are maintained, service life is extended, and the efficiency of the pipeline system is increased.

Types

Shut-off valves for heating make the operation of all equipment included in the system efficient and significantly save energy and material resources. It is installed between radiators or pipes and comes in several types:

- ball valves with different threads;

- shut-off valves;

- butterfly valves;

- flanges and fittings;

- check valves;

- valves

Ball valves

For ease of connection of heating system radiators, ball valves made of brass are chosen. A similar shut-off and control design is available with an internal thread, a union nut, an air release device and a plug. The last two are used in cases where it is necessary to remove air from the system or, conversely, to introduce air into it. Ball valves are also used when installing a pressure gauge.

Such devices are equipped with full bore balls. Each of them has a special system installed that protects the housing from damage when water freezes and prevents the spread of bacteria that appear as a result of stagnation of liquid in the pipeline.

Most ball valve models have O-rings that contact each other rather than the body surface. This increases the wear resistance of the entire crane. This type of shut-off and control part contains important information on the body regarding its installation.

Shut-off valves

To connect or disconnect a separate radiator (for the purpose of dismantling it or preventing it) in the heating system without emptying it, shut-off valves are used. They come in two types: straight and angular. Such devices are made of brass coated with nickel.

Some models are equipped with a drain valve (also made of brass), which is used to remove water from the radiator or fill it with liquid.

A hose nozzle of this design can be rotated in any direction.

Butterfly valves

This is a shut-off and control valve made in the form of a disk. The element rotates around an axis located perpendicularly or at an angle to the direction of movement of the coolant. Butterfly valves are used not only in heating systems, but also for water supply.

Check valves

Such devices are used to protect the system from unexpected loads and regulate the coolant flow in the pipeline. They can be mounted in different places. Coupled valves made of brass have threads and a gasket located on the inlet side. The entire structure operates on a spring that holds the rod. It, in turn, is recessed at a certain pressure, thereby allowing the coolant to pass through. Such equipment lasts a long time and is inexpensive.

To connect the heating system, check valves made of brass, with a stainless steel spring and a plastic rod are used. They are installed in the circuit after the circulation pump. The maximum permissible temperature for such mechanisms is 120 °C.

Also, such elements can be installed on high-pressure tanks.

Flanges

These connecting parts are used to connect fittings to pipes, connect individual parts of the pipeline, and install additional equipment. They are produced in the form of a disk or ring with holes. They are flat or collar-shaped (with a protrusion, depression, tenon, groove).

Made from steel. They are characterized by durability, a wide temperature range, and excellent anti-corrosion properties.

Fitting

Fittings are connecting elements for the heating system pipeline. These include:

- couplings (do not change the direction of the pipeline, have different outlet diameters);

- squares (change direction by 45-90°);

- tees (designs with 3 outlets for combining pipes of different diameters at different angles);

- crosses (for 4 pipes perpendicular to each other or located at a certain angle);

- plugs (put on the end of the pipe).

Valves

The design of this part includes a metal body, a control lever, and a butterfly valve. Such a mechanism is equipped with a locking element located perpendicular to the coolant flow. The regulating function of this element is not provided. It operates in 2 positions: “open” or “closed”.

The cross-section of the valves almost coincides with the diameter of the pipes. Such elements are distinguished by their simplicity of design and low level of hydraulic resistance. It is especially advantageous to use them in main pipelines.

Today, plastic and metal-plastic pipes are increasingly being chosen for heating systems; accordingly, polypropylene fittings for heating radiators are used with them.

It is placed on each element of the system separately. Date: September 25, 2021

Water supply heating installation services

LLC DESIGN PRESTIGE 8(495)744-67-74

In addition to fast and high-quality repair of heating pipes, we provide professional installation of turnkey heating systems. On our heating page > resant.ru/otoplenie-doma < you can view and get acquainted with examples of our work. But to be more precise, it is better to check with an engineer about the cost of work and equipment.

To contact us, use the contact number of DESIGN PRESTIGE LLC 8(495) 744-67-74 , which you can call around the clock.

Heating from DESIGN PRESTIGE LLC Type: water here > /otoplenie-dachi.html

note

Our company DESIGN PRESTIGE LLC is part of the non-profit organization ANO INTERREGIONAL BOARD OF FORENSIC EXPERTS. We also provide independent construction technical expertise services.

Heating cost calculation

The cost of repairing heating systems

Cost of installation of water supply

Similar services:

- Welding metal heating pipes When installing heating pipes, you often have to connect them by welding. Of course, in some cases a threaded connection may be suitable, however...

- Pipeline welding The method of electric arc welding of pipelines is often used in the installation or manufacture of technological lines. They are produced on direct or alternating current. Economical,…

- Welding gas pipes Welding gas pipes requires real professionalism, which is quite dangerous. You need to work quickly and efficiently. Before starting the connection, the edges of the pipes are processed:...

- Welding profile pipes The main method of welding profile pipes is the usual butt joint of the ends. It is performed using the arc or gas method, but due to its simplicity and…

- Welding galvanized pipes Special technology for welding galvanized pipes allows you to connect them without disturbing the zinc coating. Flux is applied to the joint area, which provides...

- Welding pipes using manual arc welding When welding pipes using manual arc welding, professionals advise making a triple seam - it will be more reliable than a single one. It is most convenient for a welder to work...

- When welding a fixed pipe When welding a rigidly fixed pipe, a different technique is used: the first seam is made from the bottom up to half the diameter of the pipe, and then lowered...

- Welding of steel pipes The welding of steel pipes remains the most popular - both in production and in everyday life. The qualifications of the welder play a significant role here...

- Burner repair consists of: • Cleaning the fuel filter. • Cleaning the burner from soot. • If necessary, replace the nozzle. • Cleaning the heater from soot •…

- Features and types of welding of steel pipes One of the most popular types of work on the market is welding of steel pipes. This work can be carried out not only in large…

- Pipe welding The success of such a complex connection largely depends on the correct choice of pipe welding method, which is chosen for a particular type of metal. IN…

- Features of manual arc welding It is performed in several passes, after each it is necessary to remove the slag. Each subsequent seam is made overlapping the previous one. This method allows you to achieve...

- Welding vertical pipes In some cases, welding is very difficult. For example, it is difficult to weld pipes that are in a vertical position. This kind of welding...

- Automatic pipe welding and preparation for welding Modern welding technologies have made great strides forward. One of the areas is automatic pipe welding. With the use of automatic welding, it became possible to eliminate…

- Welding vertical pipes The second and third seams are performed with slow movements. The beginning and end of the seam are shifted by 3 centimeters. The last seam is made straight and...

- Heating repair at the dacha Repair of the boiler room, boiler equipment Installation and replacement of heating radiators Installation and repair of heating systems Repair of heating pipes at the dacha We will…

- Welding process You should start welding heating pipes with tacks. This is the technology of butt connection. They are part of the seam. To perform them, electrodes are used...

- Repair and adjustment of automation systems Modern boiler houses are equipped with automated systems with varying degrees of complexity, designed to ensure the normal functioning of the boiler without the constant presence of a person. Boiler room…

- Repair and maintenance of boiler rooms This boiler room needs repair! There is nothing to serve here. The concepts of boiler room repair and maintenance have subtle but significant differences for the uninitiated:…

- Welding of components and parts After this stage, having ensured that the joints are aligned correctly, the seam is welded. Before the first pass, use electrodes of a smaller diameter, for example...

THE LATCH IS FULLY ADJUSTABLE FROM 0 TO 100.

The whole spectrum and without narrowing. considering very dirty risers - the best choice for durability.

The first time it was installed during installation in Berdsk - to the system administrator Kenguryakh.

Initial data: riser 1 inch And the customer's desire

kenguraha

: When installing a new radiator, I would like to preserve the flow area as much as possible.

There are several methods without narrowing the riser:

Kangaroo is not Australia!

This is not an ordinary Berd sysadmin: he worked for a long time at the Institute of Mathematics in the Academy, in short, an Associate Professor - and very jumpy! What are they doing there? Are they calculating the correct equipment for heating installation? This kangaroo quickly and briskly jumped over the smoked one: at 3/4 of the tap there is also a narrowing - let’s set the tap to 1 inch!

kenguraha:

I would like to be able to regulate the heat output of the radiator. What options are there for this, given the diameter of the riser? Okay, I think: now we’ll quickly break down this mathematician: a narrowing always occurs on the thermostatic control valve:

purely structurally - additional hydraulic resistance:

When fully open, it allows 3 times less water to pass through than a full-flow faucet.

And the old woman has a problem: it turns out there is a wedge valve on sale - full bore. Full adjustment from 100% to 0% (the entire range and without narrowing).

Summary: The Australian jumping kangaroo is better at:

Photo of the actual installation: Minsk cast iron radiator - a classic. The order was made in the style of nostalgia: “a boiler room made from a scoop” - we are all made in the USSR. Taps and valves, pipe bends and no modern bimetal: everything is specially selected according to the design of that era.

An alien battery from another galaxy - a heavenly, cosmic hue.

Blatnoy, elite radiator of “blue bloods” - fans of acrylic bathtubs do not understand this.

And those who like polypropylene (cellophane layers) for heating will generally spit.

Kenguryakha's review: